Auftragsfertigung der Extraklasse

C 22 UP | Zollner Elektronik AG | Electrical engineering

In prototype construction, sample series production, and tool making, the system solutions specialist of the mechatronics service providers - the Bavarian family business Zollner Elektronik AG - already relies on CNC machining centres from Hermle and their high level of automation.

"Zollner - Solutions for your ideas" - solution expertise for complex mechatronic systems from the development stage to after-sales services: As a globally active partner of major corporations as well as for small and medium-sized businesses, Zollner AG offers its customers complete cross-sector solutions for the entire life cycle of products. Founded by Manfred Zollner in Zandt, Bavaria, in 1965, this one-man operation has developed into a globally active contract manufacturer and service provider that is now one of the top 15 providers of electronic manufacturing services (EMS). Around 8700 people are employed by the company at 17 production locations in Germany, Hungary, Romania, China, Tunisia, the US, Switzerland, and Costa Rica. More than 50% of these are based in Germany, with a good 2500 at the main Zandt plant alone. The Zollner Group is active in the fields of industrial electronics, railway technology, automotives, medical technology, aeronautics and defence, measurement technology, office electronics and data technology, other consumer goods, and telecommunications. It relies upon long-standing, sustainable partnerships. Based on a philosophy of a high, largely self-sufficient level of in-house production, the products and services offered by Zollner are characterized by their high quality and optimum price-performance ratio. Technological advantage and a best-cost country strategy along the entire value creation chain go without saying and are demonstrated at all plants, in the interests of the customer and the services tailored in accordance with the customer's wishes. In the end, the customer decides about the used process depth, whether the products are individual parts, modules, devices, or complex systems. As an established service specialist without its own products, Zollner's focus is on performance and service for the customer in all regards, which requires application, a command of all relevant disciplines, and the consistent use of the latest technologies.

-

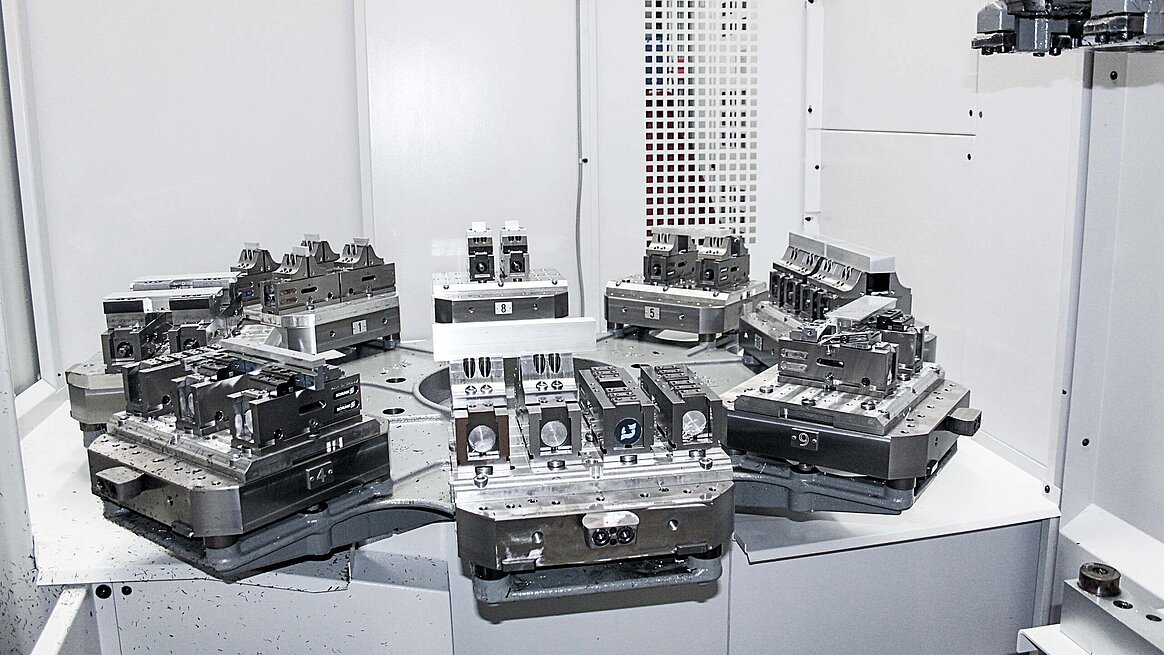

The pallet magazine with eight 320 x 320 mm pallets and - above right - the gripper system of the gantry handling device for handling the interchangeable pallets; in total, the system contains 11 320 x 320 mm interchangeable pallets, which can have different or the same clamping fixtures as required -

The setup station for (in this case) 320 x 320 mm pallets for the process-simultaneous setup of pallets with clamping technology or workpieces -

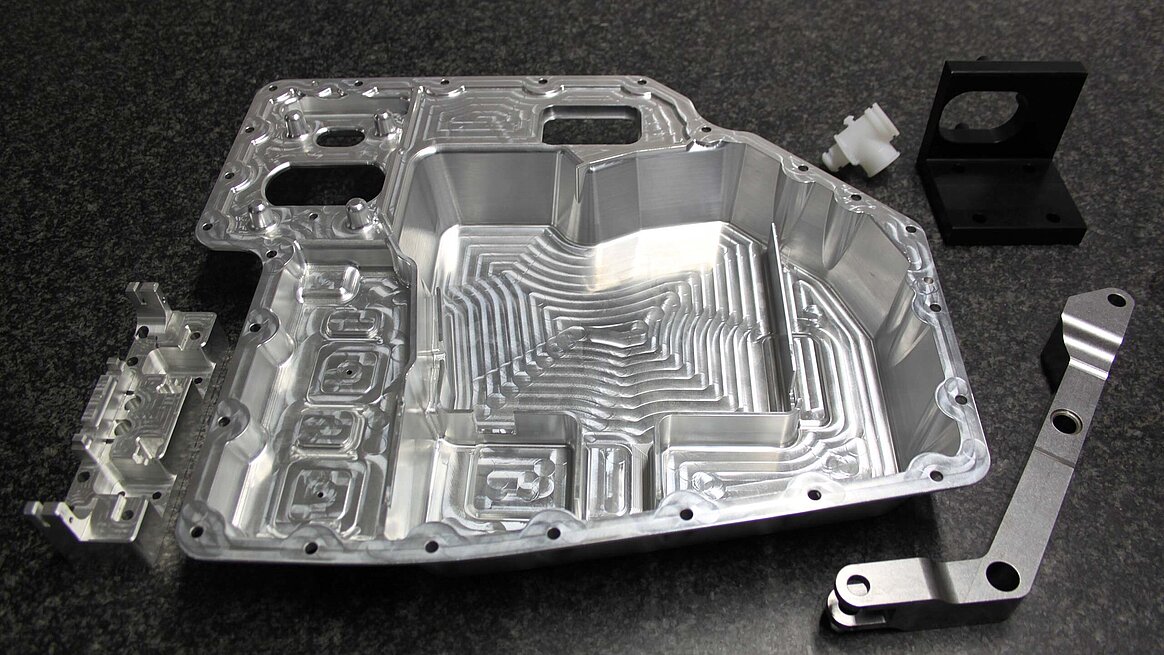

A small selection of milled workpieces manufactured from diverse materials, some of which were produced using 5-axis technology from solid blanks

Universally flexible 5-axis equipment for a faster time to market

Factors of success that cannot be ignored include the creativity to make developments and the flexibility to realise traditional simultaneous engineering (SE) projects as well as the usage and capacity-oriented availability of production technology equipment for the prompt production of prototypes, sample series, and complex production parts. Johann Dietl, Head of the Mechanics Division of Zollner Elektronik AG at the main Zandt plant, explains: "We are industrial service providers, and manufacture extremely complex parts, subassemblies, and devices in accordance with customer requirements. This means that for a fast time-to-market, we really need to produce functional prototypes and sample series in the first instance.

In 2009, we therefore started an investment project with the aim of rationalising manufacturing in the areas of prototype construction, sample series, and tool making, carrying out comprehensive evaluations with regard to 5-axis machining centres. Following intensive, challenging milling tests, Hermle AG emerged as the victor, because we were convinced by the overall package of three tool axes and two workpiece axes, high dynamics for all conceivable milling and complete machining operations, individual set-up possibilities, cost-benefit ratio, and the service concept, which has attracted all-round praise." Initially, a 5-axis CNC high-performance C 40 U machining centre from the Berthold Hermle AG machine factory, 78559 Gosheim, Germany was installed. Over the last few years, this has been joined by a further nine Hermle machining centres with varying frame sizes and output capacities. The first machining centre was equipped with an enhanced level of automation in comparison with the standard scope of delivery. This took the form of an additional tool magazine with 87 spaces, a swivelling rotary table with a diameter of 420 mm, a zero point clamping system, a touch probe, and a tool breakage control system.

3-shift usability and application flexibility

Today, the Hermle machining centres that have been gradually installed over the last few years cover a wide application range from 3-axis to 5-axis/5-side simultaneous/complete machining for workpiece dimensions of up to 800 x 800 x 550 mm and workpiece weights of up to 1400 kg. Johann Dietl says the following about the requirements and corresponding usage strategy for the Hermle machining centres: "Depending on the complexity of the workpieces, cycles of a few minutes to several hours must be taken into account. We manufacture batches of between 1 piece and 200 pieces in size, often producing families of milled components as a set in order to enable the optimum organisation of the logistical link to downstream production. Thanks to the high process depth that we use for manufacturing sheet metal, plastic parts, and turned or milled components - with a good 3000 of these seeing changes each year - we require a really high level of usage, application, and usability flexibility. This is why all of our 5-axis machining centres have an additional magazine with 87 tool pockets, so that we are able to machine even complex workpieces in our well-established 3-shift schedule without retrofitting or refitting tools. Normally, all of our machines are running at all times. Our last installed machines - 5-axis high-performance CNC machining centres of type C 22 UP - have been equipped with an 11-compartment pallet magazine, too. This means that we benefit from highly flexible, 24/7, self-sufficient manufacturing in automatic mode as well as technician-operated work as is required occasionally due to priority changes." Separate programming stations are assigned to the Hermle machining centres in order to enable their features to be used optimally and as fully as possible. Thanks to the integrated 11-compartment pallet magazines and tool breakage monitoring function on the machining centres, this enables long machine cycles to be achieved, as permitted, too, by multiple-machine assignment and simultaneous workshop programming. For the 5-axis machining centres, the universally identically equipment philosophy using HSK-A63 tool holding fixtures, spindle speeds of up to 18000 rpm, a zero point clamping system, and/or pallet holding fixtures, additional tool magazines, and similar accessories becomes important here.

The final case in favour of automated single part manufacturing

Hans-Werner Hoppe, an authorised representative of Hermle + Partner Vertriebs GmbH and responsible for the company's major customer Zollner Elektronik AG, has the following to say about the features of the two further automated 5-axis high-performance C 22 UP machining centres at the Zollner Mechanics-Mechatronics Department in Zandt (MZ3): "With a working range of X = 450 x Y = 600 x Z = 330 mm, the C 22 UP machining centres are compatible with the majority of the workpieces of Zollner's customers. The standard machining centres are equipped with 55 tools, and the additional magazines with 87 pockets expand the application areas to an extremely wide spectrum of parts and component families without any need for retrofitting. With spindle speeds of 18000 rpm and the HSK-A63 tool holding fixture, we can use optimum tools for highly productive roughing and precision finishing. Equipped with swivelling rotary tables with a diameter of 320 mm and holding fixtures for 320 x 320 mm interchangeable pallets, these machining centres enable fully automated 5-axis milling on workpieces of all levels of complexity - for both single parts and series components. A further advantage of the C 22 UP machining centres with their additional pallet magazine and gantry handling device is their extremely compact design, which meets customers' wishes for as small a footprint as possible and in one case at Zollner even allowed a "shoehorn" installation.