Available on demand

The subcontractor CNC-Welcker specialises in medical technology, aerospace, the optical industry, gas and microscanning technology, as well as mechanical and plant engineering. Its promise: To deliver perfect quality, even when significant time elapses between orders. Thanks to the RS 2 robot system from HERMLE and the two adapted C 32 U 5-axis machining centres, the company now achieves its goal with ease.

Changing the clocks or sales – some things are rare but recur regularly. “It’s the same with some of our customers,” says managing director Torsten Welcker. “We manufacture components for them on our machines in small to medium quantities, often recurring over several years, complex and sometimes just a few dozen workpieces.” The graduate engineer has been managing CNC-Zerspanungstechnik Welcker GmbH in Reichelsheim, Wetterau, with over 20 employees since 1995. The company was founded in 1973 by his father, Erich, who brought his dream to life with a master craftsman’s certificate and a lathe in his basement workshop.

Always a priority, even back then: Precision and repeat accuracy. “We focus on quality. Our customers can count on us to fulfil follow-up orders with the highest level of precision,” claims operations manager Bernd Schuff. However, machining rarely produced components involves a great deal of effort. Knowledge of specific requirements is not always readily accessible to employees, thus increasing the likelihood of errors.

“That’s why we now rely on automation,” say Torsten Welcker and Bernd Schuff in unison. The goal: In the mornings, qualified employees program and set up the systems to prepare everything for the unmanned shift. “That works very well. It allows us to achieve significantly longer machine runtimes and unprecedented reproducibility,” explains managing director Welcker, who then also gives an example: “We produced a complex component for a customer on our fully automated system according to a three-page test plan precisely to a hundredth of a millimetre. When the follow-up order arrived a year later, we initiated machining at the push of a button, and the first workpiece was already flawless. That’s really fun.”

When it comes to the crunch

CNC-Welcker has been relying on precision from Gosheim for 20 years. “In 2005, we entered the field of 5-axis machining with the C 600 U from HERMLE,” explains the managing director. “I was completely convinced of its possibilities.” Since then, this machine tool has been a cornerstone of the technology park. “It’s one of the systems that fails the least,” says Bernd Schuff. “And if anything wears out or breaks, the HERMLE service is excellent. I’ve seen nothing comparable on the market. That has gotten us out of a tight spot more than once.” In the following years, two C 20 U machines were added to further leverage the benefits of 5-axis machining.

In 2015, the company took its first step towards automated milling with a C 22 UP fitted with an adapted PW 150 pallet changer. “The HERMLE machine fits our component sizes perfectly,” says Torsten Welcker. Thanks to the pallet changer with eleven pockets, the company can produce complex aluminium precision parts in medium series overnight without any personnel on-site. “The system makes it easier to maintain the required quality in the long term. Because even the best worker cannot achieve this high level of reproducibility,” remarks Bernd Schuff. Torsten Welcker adds: “Still, the system is only as good as the operator behind it. They simply have to match each other.”

That is why the company consistently prioritises ongoing training. “In the first three months of this year alone, our CNC millers have attended four CAM training courses. We like to surround ourselves with people who are truly passionate about machining, eager to experiment and committed to personal growth,” emphasises Torsten Welcker.

-

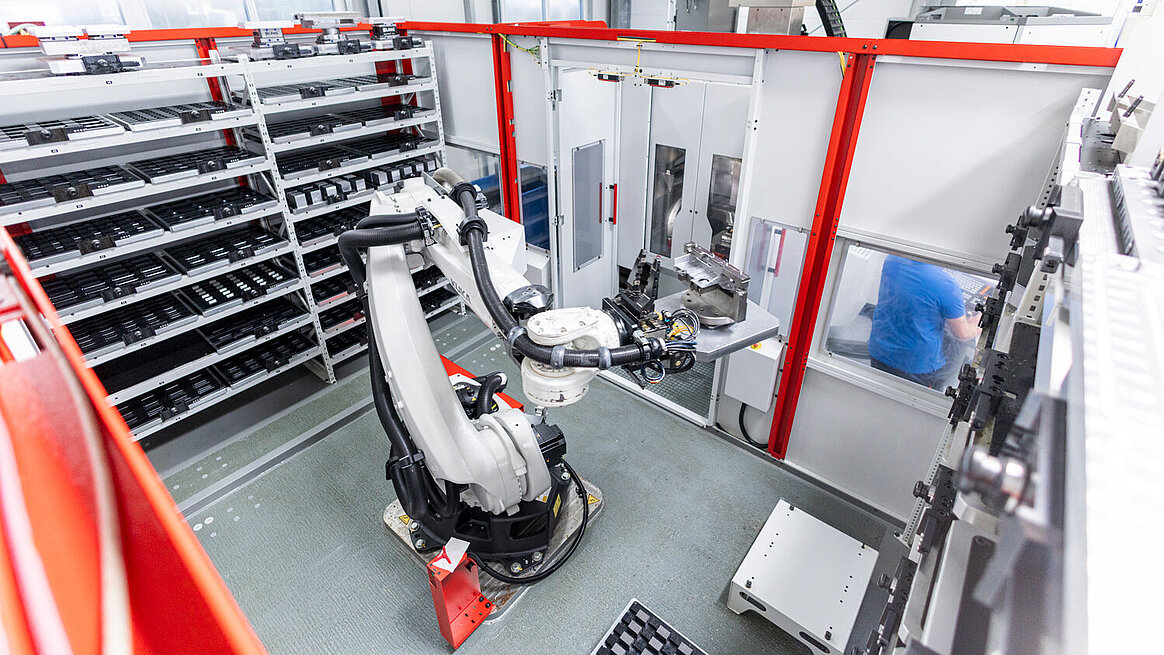

CNC-Welcker built a new workshop for the RS 2 robot system with two adapted C 32 U machines from HERMLE. -

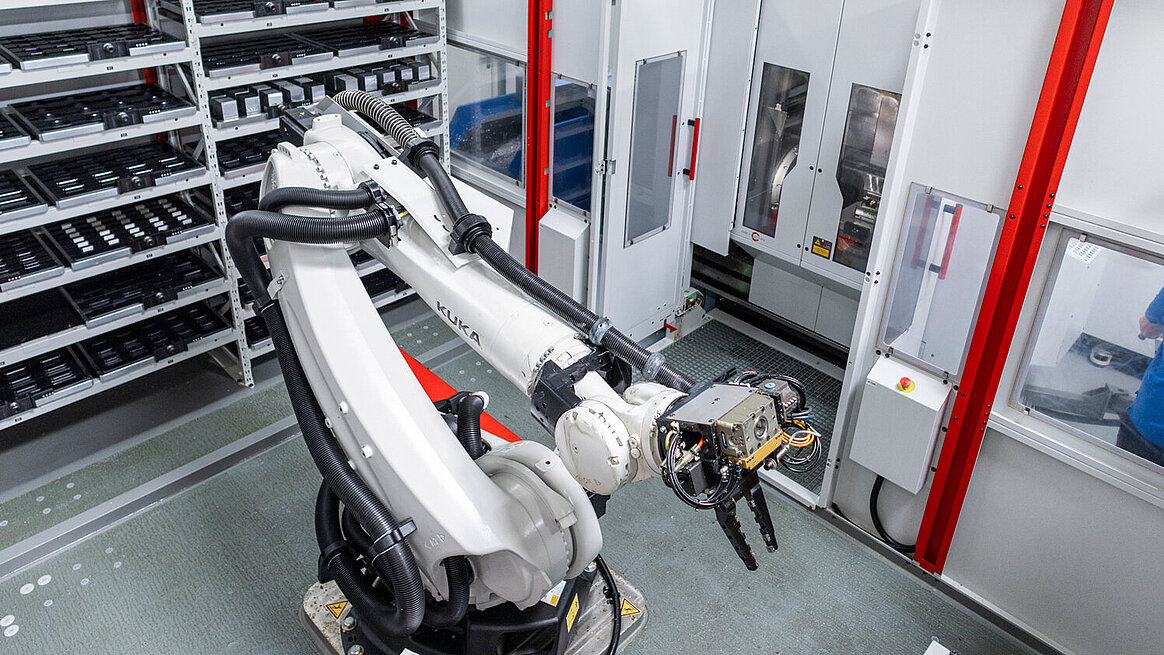

47 dies and eight pallets in the robot system, 750 tools in the machining centres – the possibilities are virtually unlimited. -

47 dies and eight pallets in the robot system, 750 tools in the machining centres – the possibilities are virtually unlimited. -

The C 32 U 5-axis machining centre from HERMLE is characterised by maximum precision and reproducibility. -

The experts from CNC-Welcker: Timo Stock and Rami Sonntag with operations manager Bernd Schuff and managing director Torsten Welcker (from left) -

CNC-Welcker entered the field of automation in 2015 with a C 22 UP and its PW 150 pallet changer.

Chicken or the egg

The shift to individual part handling with the RS 2 robot system from HERMLE was inevitable. Torsten Welcker asks: “Do I wait for the order to come in and then buy a machine, or do I make the upfront investment and provide the capacity?” and then answers the question himself: “We decided to invest.” In 2019, the company built a new workshop to house the robot system and two adapted C 32 U 5-axis machining centres. Welcker started out with one machine tool. Eighteen months before the COVID-19 pandemic began, the company secured a major customer in the ventilator sector and has since been producing the components fully automatically on the system.

“With the onset of the pandemic, we had to ramp up capacity significantly and wanted to procure a second C 32 U as quickly as possible,” says Bernd Schuff, looking back. The system from Gosheim was installed in just two months. “And only six weeks later, it was running at full capacity – just like our first C 32 U. The machines were running around the clock,” recalls Torsten Welcker.

Around 750 tools are stored in the two double additional magazines ZM462. “This enables us to handle every task reliably,” emphasises the operations manager. The RS 2 robot system accommodates 47 dies and eight pallets, with gripping and clamping technology engineered for fully automatic 24/7 production – handling both individual parts and pallets. “We can pre-set over 100 different orders and start them at the push of a button, that’s more than enough to cover the weekend,” says the managing director with satisfaction. “We’re thus perfectly prepared for the future.”