News

Contact: Maschinenfabrik Berthold HERMLE AG / Marketing Department / Email: marketing@hermle.de

HERMLE continues to sense an uncertain environment in 2025

02.07.2025

HERMLE continues to sense an uncertain environment in 2025. Incoming orders decline by 7% to €193.3 million by the end of May Group turnover down 6% to €178.6 million

HERMLE continues to sense an uncertain environment in 2025. Incoming orders decline by 7% to €193.3 million by the end of May Group turnover down 6% to €178.6 million

Generation 2 from HERMLE – a new era of machining centres and automation solutions – live at EMO 2025

28.06.2025

With three fully automated systems and a mill-turn machining centre, HERMLE relies on proven tradition – coupled with the latest innovation. All models will be exhibited in GEN2 design, each with interesting machining examples.

With three fully automated systems and a mill-turn machining centre, HERMLE relies on proven tradition – coupled with the latest innovation. All models will be exhibited in GEN2 design, each with interesting machining examples.

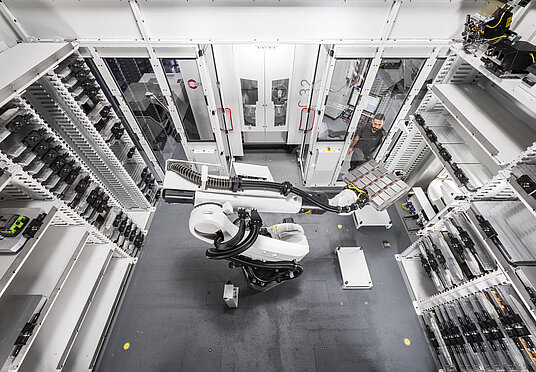

The handling system HS flex hybrid– the logical further development for easy entry into automation

14.05.2025

Our handling systems HS flex and HS flex heavy demonstrate their efficiency daily in numerous companies and a multitude of applications for the automated production of a wide variety of parts.

Our handling systems HS flex and HS flex heavy demonstrate their efficiency daily in numerous companies and a multitude of applications for the automated production of a wide variety of parts.

As expected, HERMLE reports downturns in Q1 2025

14.05.2025

As expected, HERMLE reports downturns in Q1 2025

As expected, HERMLE reports downturns in Q1 2025

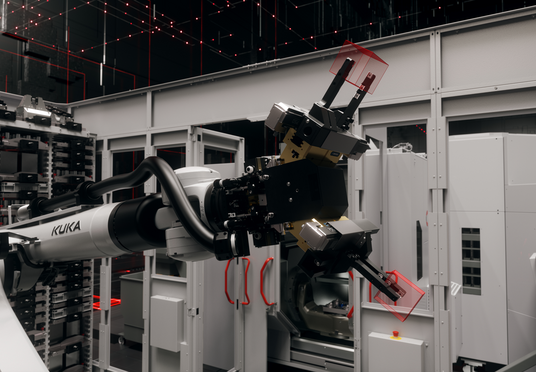

Robot system on a new level – GEN2 version of the robot system RS 2

13.05.2025

With the GEN2 version of the robot system RS 2, HERMLE AG is again taking automation to a new level. Nearly all areas of the previous RS 2 system have been enhanced and optimised to better meet customer needs.

With the GEN2 version of the robot system RS 2, HERMLE AG is again taking automation to a new level. Nearly all areas of the previous RS 2 system have been enhanced and optimised to better meet customer needs.

Annual financial statements: HERMLE challenged by an uncertain en-vironment in 2024

30.04.2025

Annual financial statements: HERMLE challenged by an uncertain en-vironment in 2024 decline in orders received, turnover and earnings

Annual financial statements: HERMLE challenged by an uncertain en-vironment in 2024 decline in orders received, turnover and earnings

As expected, turnover and earnings down on the previous year

19.03.2025

As expected, the business activities of Maschinenfabrik Berthold HERMLE AG were affected by the sluggish machine tool industry in 2024.

As expected, the business activities of Maschinenfabrik Berthold HERMLE AG were affected by the sluggish machine tool industry in 2024.

Automation at the next level – live at the HERMLE Open House 2025

12.02.2025

For more than 25 years, HERMLE AG has been providing innovative automation solutions for a wide range of parts. With the release of the RS 2 GEN2 robot system, HERMLE is taking its elite class of automation to a whole new level. A robot system featuring double hybrid gripper, automatic clamping jaw change, universal die and completely new rack modules all adapted to a C 32 five-axis machining centre (also GEN2) for economical and fully automatic pallet and parts handling.

For more than 25 years, HERMLE AG has been providing innovative automation solutions for a wide range of parts. With the release of the RS 2 GEN2 robot system, HERMLE is taking its elite class of automation to a whole new level. A robot system featuring double hybrid gripper, automatic clamping jaw change, universal die and completely new rack modules all adapted to a C 32 five-axis machining centre (also GEN2) for economical and fully automatic pallet and parts handling.

HERMLE bucks a challenging environment

19.11.2024

HERMLE bucks a challenging environment and invests in the future. Group-wide turnover after nine months down 4.5% year on year. New orders decreased by 10% to €m 337.

HERMLE bucks a challenging environment and invests in the future. Group-wide turnover after nine months down 4.5% year on year. New orders decreased by 10% to €m 337.

HERMLE observes an expected a reluctance by industry

29.08.2024

HERMLE observes an expected a reluctance by industry to invest. Incoming orders for the first six months of 2024 fell by 6% to €251 million.

HERMLE observes an expected a reluctance by industry to invest. Incoming orders for the first six months of 2024 fell by 6% to €251 million.

HERMLE impacted by the economy in the first five months of 2024

03/07/24

HERMLE impacted by the economy in the first five months of 2024 Automation solutions and internationalisation stabilise demand Forecast for the year as a whole unchanged Shareholders’ meeting approves increased distribution of €15.05 per preference share (previous year € 11.05).

HERMLE impacted by the economy in the first five months of 2024 Automation solutions and internationalisation stabilise demand Forecast for the year as a whole unchanged Shareholders’ meeting approves increased distribution of €15.05 per preference share (previous year € 11.05).

HERMLE showcasing five machining centres at AMB 2024

01/07/2024

Precision and reliability combined with automation

HERMLE is set to present five machining centres from the Performance Line and the High Performance Line series at this year’s AMB in Stuttgart, Germany. Two machining centres are automated, and one machining centre demonstrates 13 technology solutions on a single component.

Precision and reliability combined with automation

HERMLE is set to present five machining centres from the Performance Line and the High Performance Line series at this year’s AMB in Stuttgart, Germany. Two machining centres are automated, and one machining centre demonstrates 13 technology solutions on a single component.

HERMLE impacted by reluctance to invest during the first quarter of 2024

15/05/24

Maschinenfabrik Berthold HERMLE AG felt the impact of the industry’s expected reluctance to invest during the first quarter of 2024: The number of incoming orders during this period fell throughout the Group by 11.9% to €127 m compared to the corresponding period in the previous year (previous year: €144.2 m).

Maschinenfabrik Berthold HERMLE AG felt the impact of the industry’s expected reluctance to invest during the first quarter of 2024: The number of incoming orders during this period fell throughout the Group by 11.9% to €127 m compared to the corresponding period in the previous year (previous year: €144.2 m).

HERMLE Group sales rise 12% in 2023

30/04/24

Maschinenfabrik Berthold HERMLE AG reached new record levels in sales and profit in 2023. Starting with a large backlog of orders from the previous year and good demand that still continued through the beginning of the year under review, Group sales rose 12.3% in 2023 to €532.3 m (prev. year €474.1 m).

Maschinenfabrik Berthold HERMLE AG reached new record levels in sales and profit in 2023. Starting with a large backlog of orders from the previous year and good demand that still continued through the beginning of the year under review, Group sales rose 12.3% in 2023 to €532.3 m (prev. year €474.1 m).

What was good is about to get even better HERMLE GEN2

24/04/2024

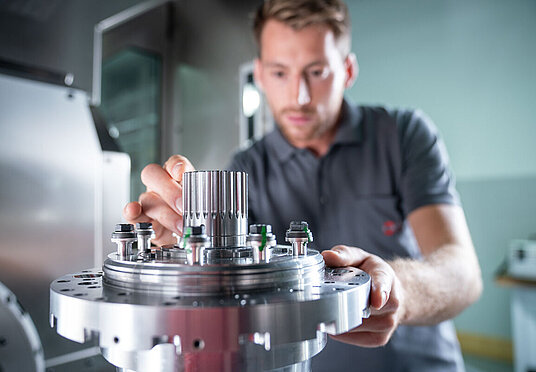

HERMLE is set to present the first three models of the new Generation 2 at this year’s Open House. Three models, namely the C 650, C 32 and C 42, were chosen and represent the medium machining segment due to their size and working area. Over the next 18 months, all machine models will be converted to the GEN2 architecture as part of a defined development process.

HERMLE is set to present the first three models of the new Generation 2 at this year’s Open House. Three models, namely the C 650, C 32 and C 42, were chosen and represent the medium machining segment due to their size and working area. Over the next 18 months, all machine models will be converted to the GEN2 architecture as part of a defined development process.

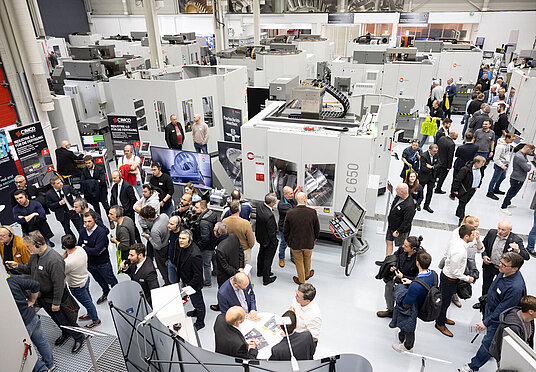

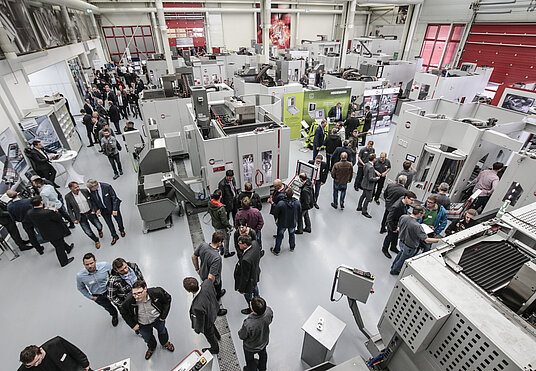

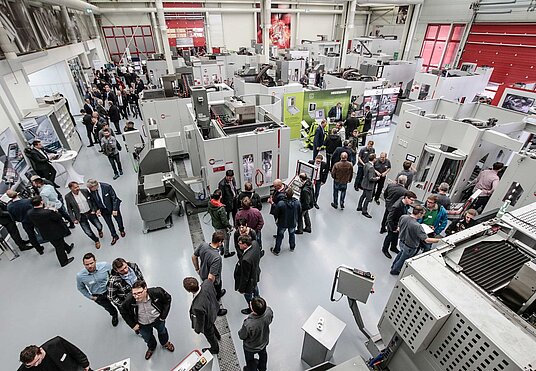

Review Open House 2024

22/04/2024

Presented as a “sector get-together with technology transfer”, the latest edition of HERMLE AG’s traditional Open House proved to be a resounding success. This year’s HERMLE Open House closed its doors at 5:00 p.m. on Friday after welcoming more than 1,100 companies and 2,550 visitors, including 750 international guests.

Presented as a “sector get-together with technology transfer”, the latest edition of HERMLE AG’s traditional Open House proved to be a resounding success. This year’s HERMLE Open House closed its doors at 5:00 p.m. on Friday after welcoming more than 1,100 companies and 2,550 visitors, including 750 international guests.

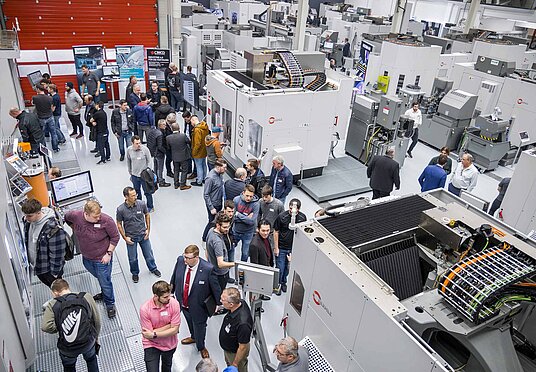

HEIDENHAIN CORP., Others Partner with HERMLE, USA, Inc. to Launch CONNECT Manufacturing Innovation Hub in Silicon Valley

Ribbon Cutting Ceremony Represents Beginning of Long-Term Collaborative Approach to Manufacturing Education

HERMLE achieved new record highs in 2023

20/03/24

According to unaudited provisional figures, Maschinenfabrik Berthold HERMLE AG achieved new record highs in turnover and result in the 2023 financial year and performed slightly better than expected overall. Compared to the previous year, the Group turn-over of the Swabian machine tool and automation specialist thus rose by around 12% to roughly €532 m (previous year: €474 m).

According to unaudited provisional figures, Maschinenfabrik Berthold HERMLE AG achieved new record highs in turnover and result in the 2023 financial year and performed slightly better than expected overall. Compared to the previous year, the Group turn-over of the Swabian machine tool and automation specialist thus rose by around 12% to roughly €532 m (previous year: €474 m).

Sector get-together with technology transfer – at the HERMLE OPEN House 2024

This year, too, HERMLE AG extends a warm welcome to its traditional Open House at Gosheim. From 16 to 19 April 2024, the factory gates open daily for visitors between 9 am and 5 pm. A comprehensive supporting programme includes technical talks, guided tours of the company, a special exhibition with over 40 exhibitors from the fields of clamping technology, CAD/CAM and hardware / software, and of course HERMLE’s proprietory manufacturing process using MPA technology.

HERMLE’s business performance in the third quarter of 2023

14/11/23

Maschinenfabrik Berthold HERMLE AG showed steady develop-ment in the third quarter of 2023. Based on the good business per-formance in the first half of the year, Group turnover of the Swa-bian automation and machine tool specialist increased by 20.3% to €m 380.9 in the first nine months compared to the corresponding period in the previous year (previous year: €m 316.7).

Maschinenfabrik Berthold HERMLE AG showed steady develop-ment in the third quarter of 2023. Based on the good business per-formance in the first half of the year, Group turnover of the Swa-bian automation and machine tool specialist increased by 20.3% to €m 380.9 in the first nine months compared to the corresponding period in the previous year (previous year: €m 316.7).

HERMLE at the EMO 2023

From 18.09.23 to 23.09.23 Maschinenfabrik Berthold HERMLE AG will be exhibiting on 560 m2 in Hall 12, Stand C30, true to its motto – everything from one source – three fully equipped automation solutions and a milling/turning machining centre. All machines showcase the technological advantages of HERMLE products with interesting machining operations.

Visitors to Hermle Open House almost back to pre-COVID levels

For four days, Maschinenfabrik Berthold Hermle AG once again opened the doors to its traditional Open House exhibition. Over 1100 companies and 2500 visitors, including 800 international guests, gained a comprehensive understanding of products, automation solutions, digitalisation, Industry 4.0 solutions and Hermle services, such as service competence, additive manufacturing and the Hermle User College.

“Original with cult status” – Hermle Open House 2023 in Gosheim

Our annual Open House has also long since enjoyed a cult-like following. Not only due to the tasty traditional Swabian Maultaschen on offer, but also because of the machining ideas that we come up with to guarantee our extensive range of machines can be experienced live.

HERMLE turnover increased by 24% to €m 261

31/08/23

Maschinenfabrik Berthold HERMLE AG performed slightly better than expected in the first half of 2023: Group turnover of the German automation and machine tool specialist increased by 24.2% to €m 261.0 compared to the corresponding period in 2022 (previous year: €m 210.2).

Maschinenfabrik Berthold HERMLE AG performed slightly better than expected in the first half of 2023: Group turnover of the German automation and machine tool specialist increased by 24.2% to €m 261.0 compared to the corresponding period in 2022 (previous year: €m 210.2).

Hermle Group turnover increased by 24% to €m 209 by May 2023

05/07/23

Maschinenfabrik Berthold Hermle AG experienced continued growth in the first five months of 2023: Group turnover of the German automation and machine tool specialist increased by 23.6% to €m 208.8 compared to the corresponding period in 2022 (previous year: €m 168.9). Integrated automation solutions equipped with Hermle digitalisation modules developed particularly well.

Maschinenfabrik Berthold Hermle AG experienced continued growth in the first five months of 2023: Group turnover of the German automation and machine tool specialist increased by 23.6% to €m 208.8 compared to the corresponding period in 2022 (previous year: €m 168.9). Integrated automation solutions equipped with Hermle digitalisation modules developed particularly well.

Hermle received 5% more new orders in the first half of 2023

11/05/2023

Compared with the corresponding period of the previous year, the incoming orders at Maschinenfabrik Berthold Hermle AG rose throughout the Group by 5.2% to €m 144.2 (previous year: €m 137.1) in the first three months of 2023 despite high economic uncertainty. The company experienced continued strong demand for automation solutions featuring Hermle's own digitalisation components and profited from several large individual projects.

Compared with the corresponding period of the previous year, the incoming orders at Maschinenfabrik Berthold Hermle AG rose throughout the Group by 5.2% to €m 144.2 (previous year: €m 137.1) in the first three months of 2023 despite high economic uncertainty. The company experienced continued strong demand for automation solutions featuring Hermle's own digitalisation components and profited from several large individual projects.

Hermle automation solutions enjoyed growth in 2022

28/04/2023

Maschinenfabrik Berthold Hermle AG saw a double-figure upturn in the number of orders received, turnover and profits in 2022: The southern German machine tool and automation specialist was able to successfully consolidate its position as a technological leader in 5-axis machining centres, while also expanding its market share in the field of automation solutions.

Maschinenfabrik Berthold Hermle AG saw a double-figure upturn in the number of orders received, turnover and profits in 2022: The southern German machine tool and automation specialist was able to successfully consolidate its position as a technological leader in 5-axis machining centres, while also expanding its market share in the field of automation solutions.

Hermle's business performance exceeded expectations in 2022

22/03/2023

Maschinenfabrik Berthold Hermle AG performed much better than expected in the 2022 financial year. Compared with the corresponding period of the previous year, the Group turnover of the southern German machine tool and automation specialist rose, according to, as yet, unaudited provisional figures, by around 26% to approximately €m 474 (previous year: €m 376), with international sales slightly surpassing domestic sales. On a provisional basis, the Hermle Group achieved an operating result increase of roughly 33%, reaching around €m 99 (previous year: €m 74.6). In November 2022, the company announced a turnover increase of 20% and a disproportionately low increase in earnings.

Maschinenfabrik Berthold Hermle AG performed much better than expected in the 2022 financial year. Compared with the corresponding period of the previous year, the Group turnover of the southern German machine tool and automation specialist rose, according to, as yet, unaudited provisional figures, by around 26% to approximately €m 474 (previous year: €m 376), with international sales slightly surpassing domestic sales. On a provisional basis, the Hermle Group achieved an operating result increase of roughly 33%, reaching around €m 99 (previous year: €m 74.6). In November 2022, the company announced a turnover increase of 20% and a disproportionately low increase in earnings.

Hermle reports notable demand in the first three quarters of 2022

14/11/2022

Maschinenfabrik Berthold Hermle AG has recorded a sharp upturn in demand throughout 2022 compared to the same period of the previous year, which was severely impacted by the Covid-19 pandemic. The number of orders received by the southern German machine tool and automation specialist rose Group wide in the first three quarters of 2022 by 35.6% to €420.2 million.

Maschinenfabrik Berthold Hermle AG has recorded a sharp upturn in demand throughout 2022 compared to the same period of the previous year, which was severely impacted by the Covid-19 pandemic. The number of orders received by the southern German machine tool and automation specialist rose Group wide in the first three quarters of 2022 by 35.6% to €420.2 million.

Hermle’s incoming orders volume grows by 58%

31/08/2022

Maschinenfabrik Berthold Hermle AG saw continued strong demand across the board in the first half of 2022.

Maschinenfabrik Berthold Hermle AG saw continued strong demand across the board in the first half of 2022.

Continued positive business development for Hermle in the first five months of 2022

06/07/2022

Maschinenfabrik Berthold Hermle AG sees continued positive business development in 2022 despite growing risks. Incoming orders throughout the Group of the German automation and machine tool specialist rose by 75.1% to €235.3 million in the first five months of 2022 compared to the same period in 2021 (previous year €134.4 million).

Maschinenfabrik Berthold Hermle AG sees continued positive business development in 2022 despite growing risks. Incoming orders throughout the Group of the German automation and machine tool specialist rose by 75.1% to €235.3 million in the first five months of 2022 compared to the same period in 2021 (previous year €134.4 million).

Three Common Misconceptions about Five-Axis Machining

“It’s too expensive.” “It takes too much training or skilled labor.” “It’s more complex than I need.” These three refrains are often cited as reasons to not to invest in machines capable of 5-axis milling, but are they valid concerns? Let’s take a closer look at these common myths and get some insights from current Hermle owners about how 5-axis machines are making a positive impact on their businesses.

Hermle USA is riding a wave of new machine sales in early 2022

Hermle USA is off to a great start to 2022, posting one of its best sales months ever in January. Strong sales are always a great way to start off a new year, but those results are also indicators of two important industry trends that signal continuing success for the company for the foreseeable future.

Hermle maintains dynamic upward trend in the first quarter of 2022

12/05/2022

Maschinenfabrik Berthold Hermle AG has been able to build on the positive development of its business recorded at the beginning of 2022. In comparison with the corresponding period last year that was still severely impacted by the Corona pandemic and short-time work, incoming orders across the full range of the Swabian machine tool and automation specialist’s operations for the first quarter of 2022 rose by 77.6% to 137.1 million euros (previous year 77.2 million euros).

Maschinenfabrik Berthold Hermle AG has been able to build on the positive development of its business recorded at the beginning of 2022. In comparison with the corresponding period last year that was still severely impacted by the Corona pandemic and short-time work, incoming orders across the full range of the Swabian machine tool and automation specialist’s operations for the first quarter of 2022 rose by 77.6% to 137.1 million euros (previous year 77.2 million euros).

Hermle Group turnover rose by 27% in 2021

29/04/2022

Maschinenfabrik Berthold Hermle AG was again able to strongly expand its business in 2021 compared with the previous year, which was severely impacted by the COVID-19 pandemic: New orders as well as turnover and earnings of the Swabian machine tool and automation specialist increased significantly.

Maschinenfabrik Berthold Hermle AG was again able to strongly expand its business in 2021 compared with the previous year, which was severely impacted by the COVID-19 pandemic: New orders as well as turnover and earnings of the Swabian machine tool and automation specialist increased significantly.

Hermle Open House 2022 in Gosheim

When precision, reliability and long-term accuracy meet highly innovative 5-axis technology and automation expertise, Hermle machining centres are always involved. True to our motto "Milling at its best with Hermle", this interaction enables optimum conditions for the perfect cutting process.

Hermle raises forecast for 2021 growth: turnover set to climb from 20 % to 25 %

11/11/2021

Maschinenfabrik Berthold Hermle AG enjoyed surprisingly dynamic growth in the third quarter of 2021. As such, the Swabian machine tool and automation specialist is raising its forecast for the year overall.

Maschinenfabrik Berthold Hermle AG enjoyed surprisingly dynamic growth in the third quarter of 2021. As such, the Swabian machine tool and automation specialist is raising its forecast for the year overall.

Hermle posts 51 % more new orders in the first half of 2021

31/08/2021

Business has taken a significant boost at Maschinenfabrik Berthold Hermle AG in the second quarter of 2021 after a restrained beginning of the year. Group-wide orders received by the southern German machine tool and automation specialist rose in the first six months by 51.1 % compared to the same period in the previous year to €180.4 million (previous year €119.4 million).

Business has taken a significant boost at Maschinenfabrik Berthold Hermle AG in the second quarter of 2021 after a restrained beginning of the year. Group-wide orders received by the southern German machine tool and automation specialist rose in the first six months by 51.1 % compared to the same period in the previous year to €180.4 million (previous year €119.4 million).

RS 05-2 robot system with automatic finger change

The RS 05-2 robot system can be used in all areas where fully automated production of workpieces, weighing up to 5 kg, is required. Particularly in precision engineering and medical technology, the RS 05-2 shows all its advantages, such as compactness, high variability both in the rack storage and in the clamping device and gripper insert.

Hermle posts significant upward trend

07/07/2021

Hermle posts significant upward trend. At end of May 2021, orders received had risen by 28% to €134 million. Group-wide turnover of €113 million still 14% below previous year’s level. Full-year turnover expected to remain stable with growth of 10% or over achievable. Annual General Meeting approves unchanged payout of €5.05 per preference share and confirms the Supervisory Board.

Hermle posts significant upward trend. At end of May 2021, orders received had risen by 28% to €134 million. Group-wide turnover of €113 million still 14% below previous year’s level. Full-year turnover expected to remain stable with growth of 10% or over achievable. Annual General Meeting approves unchanged payout of €5.05 per preference share and confirms the Supervisory Board.

Flexibility squared – The RS 1 robot system

The RS 1 robot system is the complete combination cell for pallet and workpiece automation. This Hermle innovation delivers a convincing mix of flexibility and productivity: The rack storage concept provides for remarkably long autonomous runtimes, gripper and adapter changing is automatic, and the fully functional setup station allows for parallel setup of pallets and workpiece carriers during operation. This makes the RS 1 the right automation solution for many scenarios.

Hermle records increase in demand in the first quarter of 2021

11/05/21

Hermle records increase in demand in the first quarter of 2021

The number of orders received rises by 9.5% to €77.2 million

Turnover of €64.6 million still 18.7% below previous year’s level,

however at least the level of last year expected for the entire year

Intensive competition and rising material costs affect operating result

Hermle records increase in demand in the first quarter of 2021

The number of orders received rises by 9.5% to €77.2 million

Turnover of €64.6 million still 18.7% below previous year’s level,

however at least the level of last year expected for the entire year

Intensive competition and rising material costs affect operating result

Hermle continued to perform well in 2020

30/04/21

Maschinenfabrik Berthold Hermle AG continued to perform well in 2020, a year that was turned on its head by Covid-19. However, as expected, business performance of the southern German machine tool and automation specialist was impacted significantly by the pandemic. After a deep slump in the second quarter, demand picked up moderately through the rest of the year, but overall the number of orders received in 2020 fell by 41.5% to €242.5 million (previous year: €414.4 million.).

Maschinenfabrik Berthold Hermle AG continued to perform well in 2020, a year that was turned on its head by Covid-19. However, as expected, business performance of the southern German machine tool and automation specialist was impacted significantly by the pandemic. After a deep slump in the second quarter, demand picked up moderately through the rest of the year, but overall the number of orders received in 2020 fell by 41.5% to €242.5 million (previous year: €414.4 million.).

Hermle 2020: Solid results despite the COVID-19 pandemic

17/03/21

Maschinenfabrik Berthold Hermle AG performed well in 2020 despite all the challenges it faced, although its business figures were down slightly due to the impact of the COVID-19 pandemic. Based on preliminary, as yet unaudited, data, the southern German machine tool and automation specialist achieved consolidated sales of more than €296 m (previous year €463.1 m) over the past financial year.

Maschinenfabrik Berthold Hermle AG performed well in 2020 despite all the challenges it faced, although its business figures were down slightly due to the impact of the COVID-19 pandemic. Based on preliminary, as yet unaudited, data, the southern German machine tool and automation specialist achieved consolidated sales of more than €296 m (previous year €463.1 m) over the past financial year.

Mill-turn technology for more efficient flying

Complex geometries, highly durable materials and uninterrupted process monitoring are decisive factors for safety and progress in manufacturing. Hermle's response to the demanding challenges involved in producing rotationally symmetrical engine components such as blisks is represented by the mill-turn variants of its High-Performance machining centres.

Additive machining at supersonic speed

The new machining centre MPA 42 is powerful and precise but it is not for sale. When it comes to additive manufacturing, Hermle acts as a service provider.

Hermle USA has invested USD 3 million to extend its US headquarters

Hermle USA, Inc. announced the completion of the three million dollar building extension project. This doubled the size of the North American headquarters in Franklin, Wisconsin and included refurbishment of the existing building. The expansion represents a clear sign from the German machine tool manufacturer that it is willing to raise its profile to provide even better levels of support to the growing North American customer base.

Perfection in automation

22 years ago, Hermle started developing its own automation solutions for its 5-axis machining centres. Much has changed since then: The focus is no longer on reducing setting up times, but rather on even longer automated production runs. And digitalization is generating further impulses of its own. Hermle's basic philosophy, however, remains the same: One provider for a complete package – from the initial draft for a plant through to servicing beyond the guarantee period.

Handling system HS flex heavy - the Hermle automation solution with up to 1200 kg of transport weight

The rotary, lifting and linear axes of the handling unit enable precise movement of the heavy workpieces up to 1200 kg, including the pallet, between the setup station, storage modules and the machining centre’s working area. With crane loading of machining centres, workpieces with even higher weight and dimensions can be moved into the machine working area.

New, ultra-modern sheet metal production facility at its installation location in Zimmern o.R.

The groundbreaking ceremony on 5 November 2019 marked the beginning of building work on Maschinenfabrik Berthold Hermle AG’s new, ultra-modern sheet metal production facility complete with office complex. Hermle AG has been manufacturing its mineral casting beds and various other components at the Inkom-Südwest industrial and commercial estate in Zimmern o.R. since 2016. A new production facility with an office complex and a connecting building (cold hall) is now being constructed on the four-hectare site.

Additive manufacturing in toolmaking and mould making

In a joint workshop, Hermle and Trumpf gave a demonstration of how to plan, make and deploy additively manufactured components in toolmaking and mould making

Hermle sent three C 42 U, five-axis machining centres with automation capability to the USA

Hermle machining centres make for intelligent fabrication of metal components. They are used in high-end sectors such as aerospace, medical technology, mechanical and precision engineering, to name just a few. The machines, that themselves achieve tolerances below 10 µm for milling and turning (a human hair has a diameter of around 70 µm), must also be given precision treatment when they are transported. So most Hermle machines are transported either by means of vehicles with air suspension or by sea. Sometimes, though, time is of the essence and the machines must be moved very quickly.

UMATI – to simplify your connectivity

The new interface will provide our customers with a simple means of integration in IT ecosystems. The semantic structure provides the basis for the manufacturer-independent plug & play networking of machine tools and could emerge as the machine tool industry standard in future.

Hermle AG is present at the EMO 2019

With six machines, four of them at the Hermle booth C 36 in Hall 12 – true to the motto „Smart technologies driving tomorrow`s production“!

Hermle presents the latest trends in mechanical engineering at its Open House

For four days, Maschinenfabrik Berthold Hermle AG once again opened the doors to its traditional Open House. Over 1000 companies and 2300 visitors, including 900 international guests, had the opportunity to obtain a comprehensive picture of products, automation solutions, digitisation, Industry 4.0 solutions and Hermle services, such as Service Competence, Generative Manufacturing and the Hermle User College.

“Sailing boat” project – MPA technology and better milling

Additive machining with MPA technology and better milling all rolled into one. To give an impressive and somewhat striking example for a component produced by both additive manufacture and subsequent machining to shape it, a sailing boat with a number of special features was presented by Hermle AG at the house exhibition 2019.

“Fritz the Bull” and “Ben the Bear”

After the bull "Fritz" already caused a sensation at the IMTS and numerous visitors had their photo snapped next to the spectacularly presented animal, “Fritz” now has a buddy: the bear "Ben". They make a great pair, because together they are the symbol of the ups and downs on the stock exchange. This will make them a perfect eye-catcher for Hermle as a stock corporation in the Hermle showroom in the future.

Hermle introduces another digital component

The digital transformation is now becoming the focus of many different production operations. Hermle is there to provide support while you chart your individual course towards Industry 4.0 and the smart factory. We offer a wide range of software solutions for improving your efficiency, precision and productivity, with our digital components representing links in the smarter production chain.

With the RS 05-2, Hermle presents the 2nd generation of its compact robot system

Since the first compact robot system was developed by Hermle-Leibinger Systemtechnik GmbH, a wholly-owned subsidiary of Maschinenfabrik Berthold Hermle AG, customer expectations and the multiplicity of the applications have increased enormously. Not only that the RS 05 robot system should be compatible with a broader range of machine models – the requests for individual storage solutions have consistently driven the system's further development. Many different installations bear witness to successful automation solutions in the range of workpieces up to 10 kg.

Hermle reports increase in incoming orders by 22% in the first six months of 2018

30/08/2018

Group turnover increases by 14% to €215 million

Operating result increases by more than 12% to €45 million

Forecast for entire fiscal year confirmed

Group turnover increases by 14% to €215 million

Operating result increases by more than 12% to €45 million

Forecast for entire fiscal year confirmed

Hermle: Strong business in the first five months 2018

04/07/2018

In the first five months of 2018, Maschinenfabrik Berthold Hermle AG registered continued high demand. As the Executive Board of the Swabian machine tool manufacturer reported at today's Annual General Meeting, the incoming orders across the Group until the end of May increased by 28.7% to €216.2 million compared with the corresponding previous-year pe-riod (previous year €168.0 million).

In the first five months of 2018, Maschinenfabrik Berthold Hermle AG registered continued high demand. As the Executive Board of the Swabian machine tool manufacturer reported at today's Annual General Meeting, the incoming orders across the Group until the end of May increased by 28.7% to €216.2 million compared with the corresponding previous-year pe-riod (previous year €168.0 million).

Hermle turnover up 15 percent in Q1 2018

15/05/2018

Maschinenfabrik Berthold Hermle AG achieved growth in line with expectations in the first quarter of 2018. Group turnover of the Swabian machine tool manufacturer increased 14.8 % against the corresponding previous year period to € 99.9 million (previous year: € 87.0 million).

Maschinenfabrik Berthold Hermle AG achieved growth in line with expectations in the first quarter of 2018. Group turnover of the Swabian machine tool manufacturer increased 14.8 % against the corresponding previous year period to € 99.9 million (previous year: € 87.0 million).

Technology meets tradition. Industry meeting at the Hermle Open House

The performance capabilities and possible application areas of Hermle machining centres were demonstrated in a clear and impressive manner through interesting examples of machining. For example, a 90 kg solid block of non-machined aluminium was transformed into a delicate 2 kg replica of the Eiffel Tower using an array of very complex milling strategies.

Swabian tradition meets high tech from various industries

Twenty machine models will be on show in various configurations and with interesting equipment from various high-tech industries to demonstrate the vast range of capabilities provided by Hermle products. The complete model range of the Performance-Line series, including the new C 650, and the High-Performance-Line series will be presented, with many of them displaying the latest automation technology.

Hermle-Leibinger Systemtechnik GmbH 20 years of ultimate automation,RS 2 Kombi

Well over 300 systems have since been installed at Hermle machines, including linear systems with up to five, robot-controlled machining centres. Production machines from other manufacturers have also been incorporated into these complex systems.

Hermle-Leibinger Systemtechnik GmbH 20 years of ultimate automation, Handling system HS flex

Well over 300 systems have since been installed at Hermle machines, including linear systems with up to five, robot-controlled machining centres. Production machines from other manufacturers have also been incorporated into these complex systems.

Machining production facility

Facts about the new production facility:

Construction period January 2016 – end of 2017

Ceiling height increased from 5 m to approx. 12.50 m

Overall height approx. 18.80 m

Length approx. 66 m

Width approx. 37 m

Reconstructed space approx. 30300 m3

Floor space approx. 2330 m2

Plant room approx. 3700 m3

Floor space approx. 700 m2

Construction period January 2016 – end of 2017

Ceiling height increased from 5 m to approx. 12.50 m

Overall height approx. 18.80 m

Length approx. 66 m

Width approx. 37 m

Reconstructed space approx. 30300 m3

Floor space approx. 2330 m2

Plant room approx. 3700 m3

Floor space approx. 700 m2

Mineral casting in Zimmern o.R., Germany

Facts about the building in Zimmern o.R.

Construction period May 2016 – June 2017

Premises 4 hectares on the Inkom industrial estate

Overall height approx. 23.50 m

Length approx. 102 m

Width approx. 32 m + 6 m administrative building

Production area approx. 3200 m2

Construction period May 2016 – June 2017

Premises 4 hectares on the Inkom industrial estate

Overall height approx. 23.50 m

Length approx. 102 m

Width approx. 32 m + 6 m administrative building

Production area approx. 3200 m2

Hermle achieves a slight increase in turnover to €402 million in 2017

21/03/2018

In 2017, the Maschinenfabrik Berthold Hermle AG was able to increase its Group turnover slightly to around €402 million (previous year: €394.0 million) according to preliminary figures. The Swabian machine tool manufacturer's growth was achieved mainly with its domestic business, while the foreign turnover remained largely stable. From the operative point of view, the results kept pace with the increased turnover.

In 2017, the Maschinenfabrik Berthold Hermle AG was able to increase its Group turnover slightly to around €402 million (previous year: €394.0 million) according to preliminary figures. The Swabian machine tool manufacturer's growth was achieved mainly with its domestic business, while the foreign turnover remained largely stable. From the operative point of view, the results kept pace with the increased turnover.

Hermle Open House 2018

Twenty machine models will be on show in various configurations and with interesting equipment from various high-tech industries to demonstrate the vast range of capabilities provided by Hermle products. The complete model range of the Performance-Line series, including the new C 650, and the High-Performance-Line series will be presented, with many of them displaying the latest automation technology.

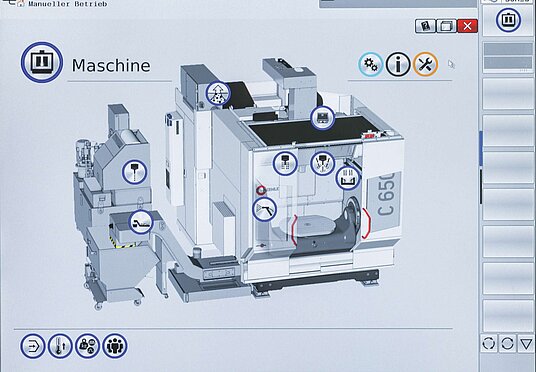

Hermle integrates the HOME screen

The HOME screen enables the individual configuration of key screen contents. Especially in combination with the software options HACS & HIMS. The HOME screen can be used with both HEIDENHAIN and SIEMENS controls.

Hermle: Incoming orders, turnover and results rise by end of September 2017

14/11/2017

The favourable business progress of the Maschinenfabrik Berthold Hermle AG has continued during the third quarter of 2017. Thus the Group turnover of the Swabian machine tool manufacturer increased in the first nine months of 2017 by 2.5 % to €280.6 million compared with the same period last year (previous year: €273.8 million), despite increasing export restrictions.

The favourable business progress of the Maschinenfabrik Berthold Hermle AG has continued during the third quarter of 2017. Thus the Group turnover of the Swabian machine tool manufacturer increased in the first nine months of 2017 by 2.5 % to €280.6 million compared with the same period last year (previous year: €273.8 million), despite increasing export restrictions.

New machine model C 650

The Hermle company has developed the C 650 to extend its Performance Line series with a major step upwards, and now provides three machine models for economical 3 and 5 axis machining. The Performance Line is positioned below the High Performance Line consisting of models C 12, C 22, C 32, C 42, C 52 and C 62, and it very nearly matches their performance capabilities. The only differences are to be found in the accessory diversity, the price and of course the naming.

Hermle at EMO 2017

With the new C 650 machine model from the Performance Line series, the Maschinenfabrik Berthold Hermle AG is presenting a new machining centre for very varied 3 axis and 5 axis jobs.

Hermle’s turnover and results rise by end of May 2017

05/07/2017

Maschinenfabrik Berthold Hermle AG performed better than expected in the first five months of 2017: As the Board of Management announced during today’s Annual General Meeting, the Group turnover of the Swabian machine tool manufacturer Hermle increased by around 7 % to € 155.7 mill. between January an May as compared with same period in the previous year (€ 146.1 mill.), with correspondingly improved results. A domestic business volume of € 72.1 mill. was generated (previous year: € 61.9 mill.) and an overseas business volume of € 83.6 mill. (previous year: € 84.2 mill.).

Maschinenfabrik Berthold Hermle AG performed better than expected in the first five months of 2017: As the Board of Management announced during today’s Annual General Meeting, the Group turnover of the Swabian machine tool manufacturer Hermle increased by around 7 % to € 155.7 mill. between January an May as compared with same period in the previous year (€ 146.1 mill.), with correspondingly improved results. A domestic business volume of € 72.1 mill. was generated (previous year: € 61.9 mill.) and an overseas business volume of € 83.6 mill. (previous year: € 84.2 mill.).