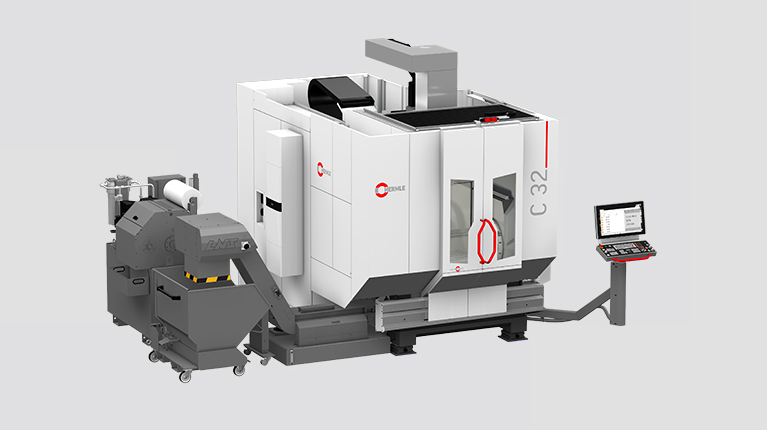

Technical Data

Dimensions

-

Traverse path: 650 x 650 x 500 mm

-

Body: Ø 650 / H 420 mm

-

Collision circle: Ø 840 mm

-

Vertical table clearance: 600 / 635 mm

Facts

-

Rotational speed: 15000/16000/20000/25000/42000 1/min

-

Rapid traverse linear X-Y-Z : 45 (60)–45 (60)–40 (60) m/min.

-

Swivelling rotary table: Ø 650 x 540 mm

-

Max. table loading: 1000 kg

Applications

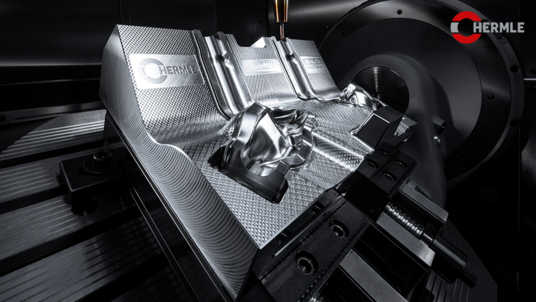

C 32 | 5-axis technology | Heavy-duty machining

HERMLE C 32 Udynamic in 5-axis version, heavy-duty machining in material Toolox 33

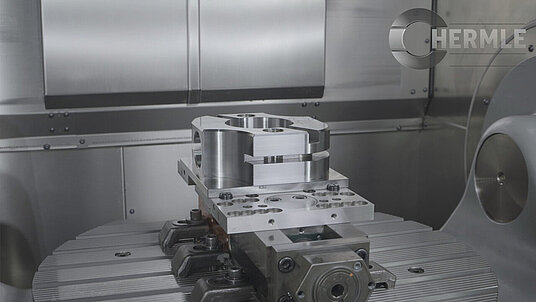

C 32 | Production technology | Steering knuckle

HERMLE C 32 U dynamic in 5-axis version, machining a steering knuckle in 1.4305 for production technology

C 32 | Tool and mould making | Pipe die

HERMLE C 32 U dynamic in 5-axis version, machining a pipe die in 1.2343 for tool and mould making, 5-axis radial machining of pipe ducts.

User reports

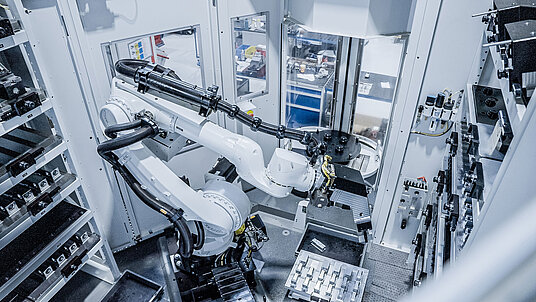

Flexibility thanks to robot automation

SWACRIT systems GmbH

Medical technology

SWACRIT systems GmbH specialises in the production of top-quality composite parts, mechatronic assemblies and high-precision mechanical components. To enhance productivity and efficiency, the high-tech company based in Tyrol, Austria, has invested in HERMLE's RS 1 robot automation solution, which enables the flexible and continuous manufacture of individual parts and components on pallets.

Accurate to the nearest hair is not precise enough

SK Technology

Prototyping

SK TECHNOLOGY is formidable when it comes to precision. That’s the result of an awareness that minute subtleties are the difference between acceptance and rejection – and a stock of machinery that can withstand critical inspection down to the micrometre range. This is where Hermle succeeds. Six automated 5-axis machining centres allow the cutting expert to be really picky.

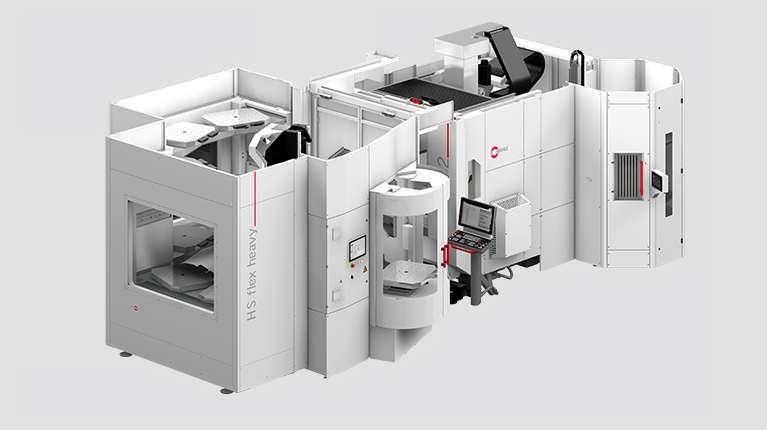

Digitalisation: the foundation for automation

Microart GmbH & Co. KG

Contract manufacturing

High variance and different batch sizes can cause many a contract manufacturer to panic – but not microart. The manufacturer of complex precision parts creates digital structures, which it combines with automated 5-axis machining centres from Hermle. The result: efficient milling with flexible capacity.