Technical Data

Dimensions

-

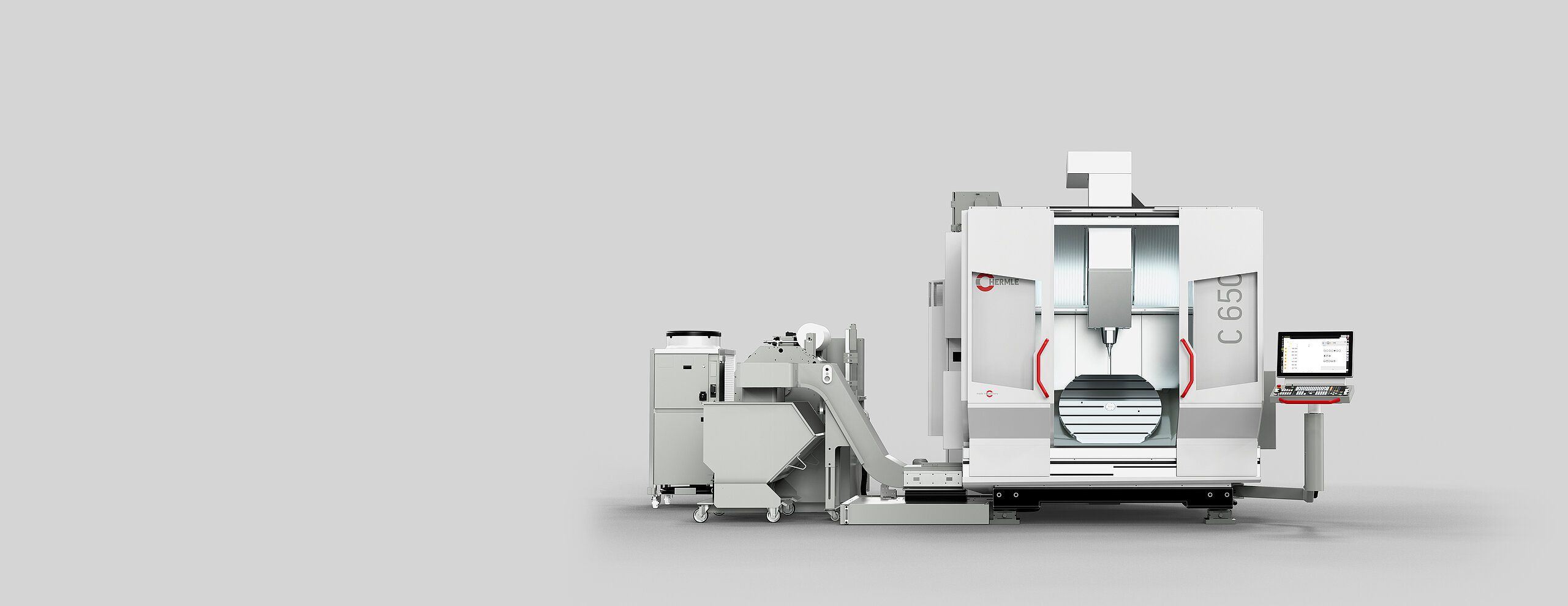

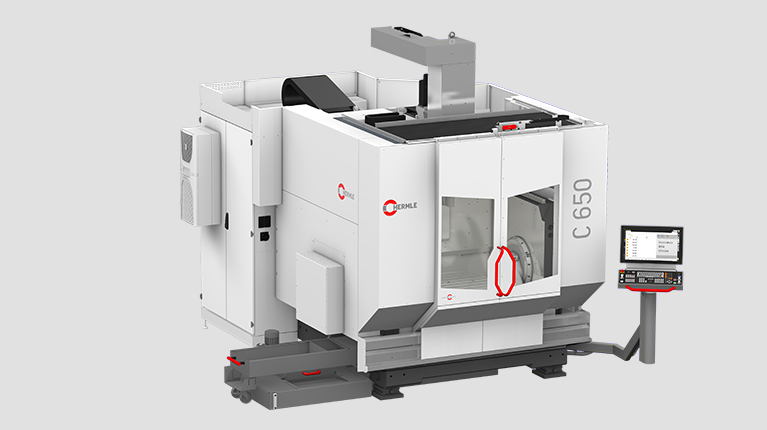

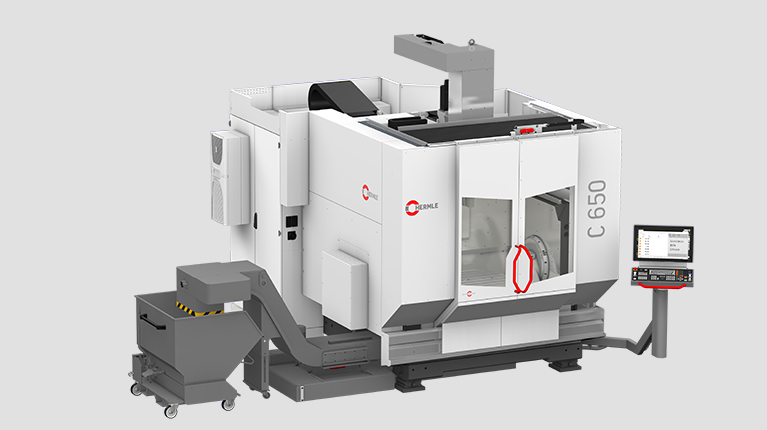

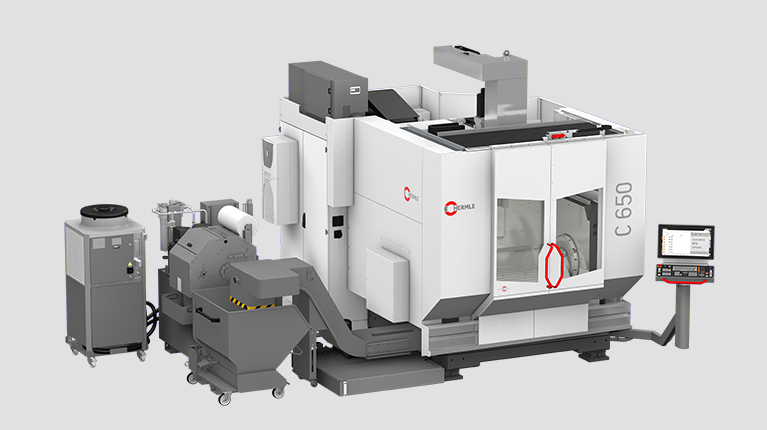

Traverse path: 1050 x 900 x 600 mm

-

Body: Ø 900 / H 600 mm

-

Collision circle: Ø 1100 mm

-

Vertical table clearance: max. 775 mm

Facts

-

Rotational speed: 15000 / 16000 / 20000 1/min

-

Rapid traverse linear X-Y-Z : 35 m/min.

-

Rigid clamping table: 1250 x 982 mm

-

Tischzuladung max.: 3000 kg

Applications

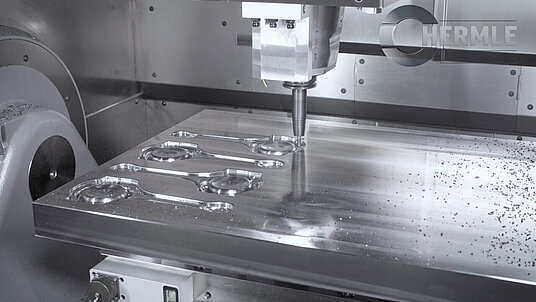

C 650 | Tool and mould making | Connecting rod

HERMLE C 650 in 5-axis version. Machining a connecting rod in 1.2312 for tool and mould making

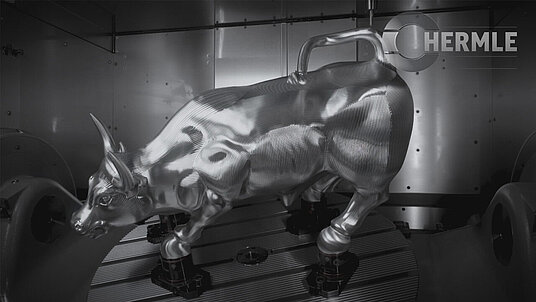

C 650 | Model making | Fritz the Bull

HERMLE C 650 in 5-axis version. Machining a bull in AlMg4.5Mn07 for model making 600 kg blank - 3.5 m3 chips - 108 kg finished part

C 650 | Model making | Van/T1

HERMLE C 650 in 5-axis version. Machining a van/T1 in AlMg4.5Mn0.7 for model making, scale 1:5. Generation of surface data by scanning an original van T1 built in 1960.

User reports

Cooler thanks to copper in the core

S&S Werkzeugbau GmbH

Spritzgusstechnik

Tool and mold making

S&S Werkzeugbau manufactures complete injection moulds entirely in-house – from design through to the initial moulding. However, the mould makers make an exception in the case of a reliable cooling solution for narrow cross-sections: Hermle Maschinenbau uses metal-powder application technology (MPA) to integrate copper into mould cores, thereby optimising heat outflow in the injection moulding process.

Update only with automation

Cafmeyer

Tool & mold making

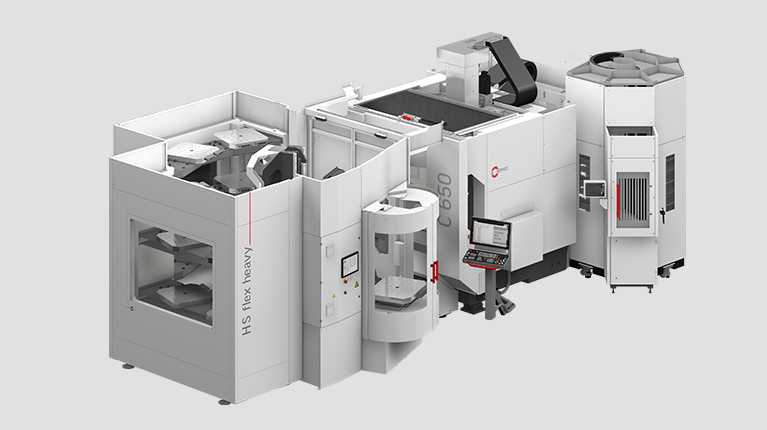

Cafmeyer manufactures press moulds. The more complex the part, the more parts needed for the mould. In the past, the Belgian mould maker was sometimes pushed to the limits of its capabilities – both in terms of dimension and capacity. The company therefore decided to invest in a Hermle C 650 U 5-axis machining centre with HS flex heavy automation.

The perfect 13 – in China | Tool technology

Huarui Precision Cutting Tools

Tool technology

Huarui Precision Cutting Tools' mission is to be one of the best suppliers of cutting tools in China. It has therefore been looking for the best machines for production – and has finally invested in thirteen 5-axis machining centres from Hermle in 2022. Hermle China not only convinced with the hardware.