Die perfekten 13 in China

C 650 | Huarui | Tool technology

Huarui Precision Cutting Tools' mission is to be one of the best suppliers of cutting tools in China. It has therefore been looking for the best machines for production – and has finally invested in thirteen 5-axis machining centres from Hermle in 2022. Hermle China not only convinced with the hardware.

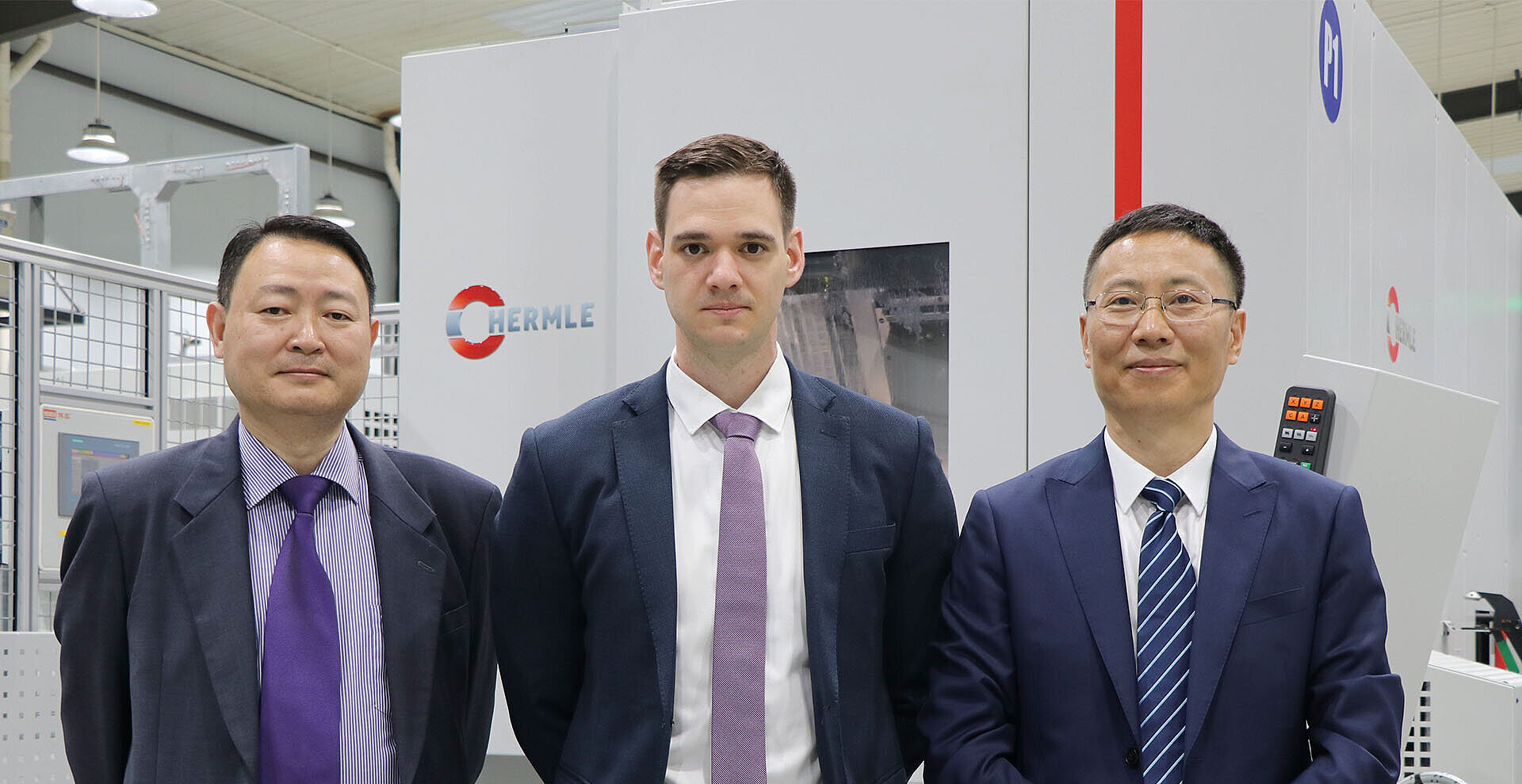

Huarui Precision Cutting Tools places high demands on itself: The Chinese company wants to be the best in its field. To achieve this, the tool manufacturer invests heavily in science and technology. "About 16 percent of the 758-strong workforce focuses on research and development," said Gao Hua, general manager of tooling systems at Huarui Precision Cutting Tools. They work on new substrates and coatings, further develop their process for precision forming and optimize the structures of the cutting tools for better chip breaking. It pays off: According to the company, product accuracy and quality have risen to such a high level since the company was founded in 2007 that Huarui Precision is one of the three biggest carbide cutting tool manufacturers in China.

For the full year 2022, Huarui Precision reported sales of 601.64 million renminbi yuan (about 79 million euros) compared to 485.48 million renminbi yuan (about 64 million euros as of May 25, 2023) a year ago.

-

Huarui Precision manufactures carbide cutting tools and tool holders in Zhuzhou for customers at home and abroad. -

Thanks to on-schedule assembly and commissioning, Huarui Precision was able to start manufacturing the tool holders on the new Hermle machining centres on schedule.

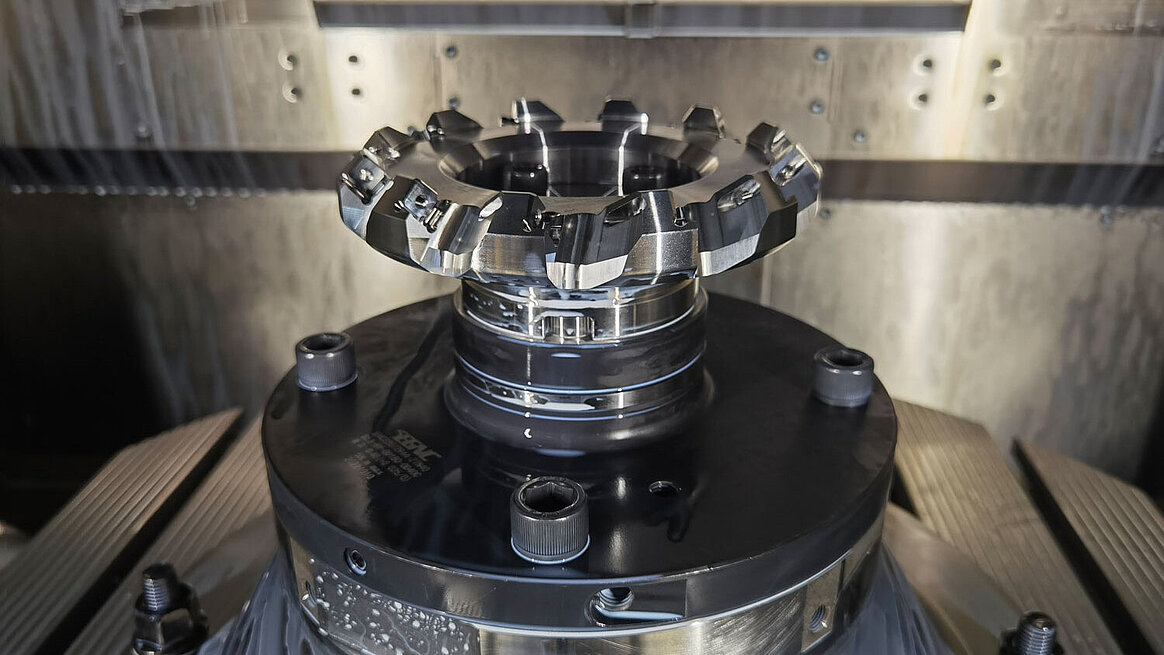

From a good reputation to a large order

Huarui Precision manufactures carbide cutting tools for turning, milling and drilling as well as tool systems and holders for customers at home and abroad. These precise carbide inserts require precise toolholders, which have been given their final shape on Hermle 5-axis milling centres since mid-2002. A total of twelve C 22 U and one C 650 U – all automated for non-stop operation – stand in the production hall in Zhuzhou (Hunan Province), some 730 kilometres north of Shenzhen. How did that happen? "I've been working in the tool industry for a long time and I know that many of the world's leading companies in the industry rely on 5-axis machining centres from Hermle,” Gao explains and adds: "I bought my first Hermle machine 20 years ago when I was working for a foreign tool manufacturer in China. It is still extremely reliable and precise. That was my reason for choosing Hermle again for this production set-up at Huarui.” His experience matches Hermle's reputation in the cutting tool industry, which demands precise milling results when machining difficult-to-machine materials. What ultimately convinced was Hermle's good reputation in the cutting tool industry, which demands precise milling results when machining materials that are difficult to machine. The Chinese tool specialist expected a lot from the milling centres: long-term stability and high accuracy even in continuous use. "We need machines that meet these characteristics in order to guarantee the high-quality standard of our cutting tools," explains the general manager.

Pioneer in China

He is also satisfied with the cooperation: In addition to the on-schedule assembly and commissioning, the remote support from the experienced engineers from Hermle China and Hermle AG helped Huarui Precision to start manufacturing the tool holders on the new machining centres. “Initially there was a problem with chip evacuation from the chuck. We were able to fix this together by changing the PLC program and adding a compressed air seal,” reports Gao Hua.

As a further milestone, he describes the direct linking of tool data and milling machines, which Hermle implemented together with Zoller. The software enables automatic tool data import from the setting device to the machining centre - in real time. "This allows us to label our tool holders with a data matrix code after measuring. When used later in the Hermle machine, this reveals all relevant data from the CNC control via a scan, thus preventing crashes caused by incorrect tool data. This makes us a pioneer in China,” emphasizes Gao Hua.

Huarui Precision Cutting Tools is strengthening its standing in the tool industry with Hermle, Gao Hue is certain. “We can rely on the Hermle milling centres. Their low failure rate ensures continuous production and prevents costly downtimes.”