Machining centres and automation solutions to meet your needs

In the CNC milling machine sector, HERMLE AG is a leading manufacturer of portal milling machines, machine tools and CNC special machines. As a machine manufacturer, our claim of “milling at its best” underlines our dedication to delivering products that consistently exceed expectations in terms of performance, machining precision and service.

Moreover, with almost 90 years of experience as a machine manufacturer, HERMLE AG comprehensively meets the demand for heightened precision and machining capacity across all sectors requiring advanced machine performance. We develop and produce CNC milling machines and special machines for the medical technology sector and general tool and mould making, as well as for the optical, aerospace and automotive industries. We also manufacture bespoke CNC machine tools as special machines, which are customised to suit our customers’ unique set of needs.

How we work

Each HERMLE machining centre contains a wealth of capabilities and values to help you stay ahead of your competitors. Learn about the 7 reasons for each HERMLE!

- Service competence

- Commitment to the site

- Precision

- Long-term precision

- Fairness

- 5-axis benchmark

- Reliability

Latest news

- What does HERMLE stand for?

HERMLE – a leading CNC milling machine manufacturer for precision machining

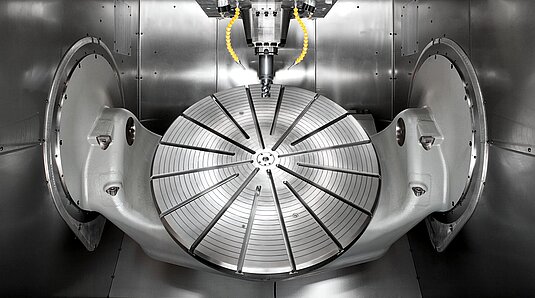

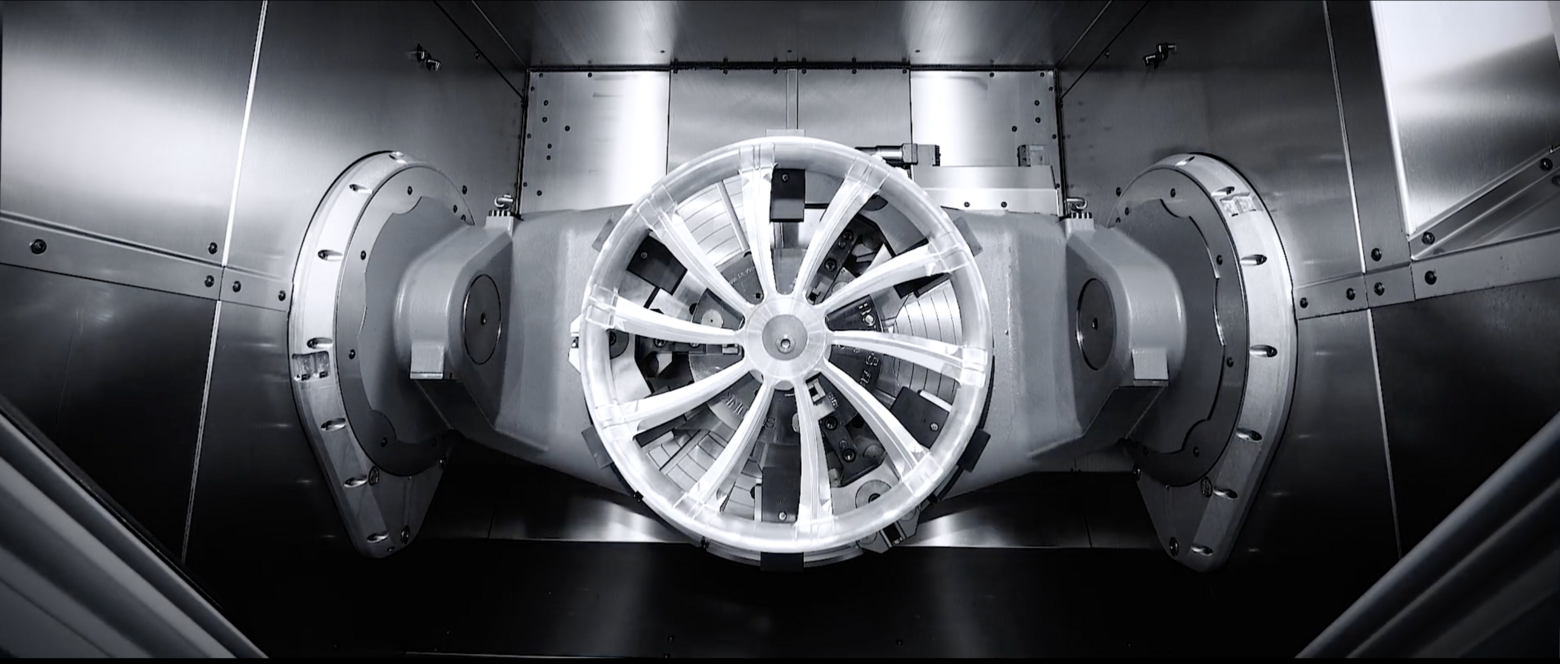

All our CNC portal milling machines are, for instance, characterised by an extremely torsion-resistant base and housing design. This enables high-precision milling of hard, brittle and tough materials. For example, high-alloy stainless steels, plastics, wood or non-ferrous metals. To achieve substantial milling depths without compromising on quality, our portal milling machines and special machines come with reinforced and wear-free axes. They are designed especially for the high reaction forces that arise during fast and high-feed milling. A quality that highlights our engineering expertise in milling machines and machine tools. Tailored controls designed for specific applications enable the precise milling of intricate shapes across a diverse range of product materials. Regardless of whether they have to move through soft materials, such as aluminium or tantalum, or hard metals, like titanium or Incoloy.

We further specialise in manufacturing special machines and machine tools for the mass production of small, complex parts that are essential for applications, like model or tool making.

Our portal milling machines can also be used for large-format product machining. For example, for the optimised face and contour milling of large plates. Due to the exceptionally sturdy design of our CNC machines, the positioning accuracy of the milling tools employed is exceptionally high, reaching up to 5/1000 mm, with consistent reliability maintained throughout (process capability). A feature that is especially relevant when achieving extensive milling depths with the utmost precision and surface quality necessitates repeated insertion of the milling tool along the same contour.

The robust and torsion-resistant design makes HERMLE milling machines much less sensitive to vibrations. This product requirement is paramount, ensuring perfect dimensional accuracy and surface quality for subsequent customer products while maintaining peak machining performance. Even difficult-to-machine, tough materials can be milled to remarkable precision and with unprecedented efficiency by our fully automatic machining centres. This is where HERMLE’s promise of “milling at its best” becomes a tangible reality.

*CNC machines (computerised numerical control) are machine tools that automatically produce complex workpieces with unparalleled precision by utilising control technology. They are primarily used for chip removal processes, e.g. milling, using products like portal milling machines or special machines.

HERMLE AG – a machine factory like no other

HERMLE is the leading manufacturer in this specific sector. Since we specialise in manufacturing machines for applications with a demand for heightened precision and machining capacity, rather than simply delivering run-of-the-mill solutions. Even though Gosheim - home to our headquarters - barely qualifies as a town with just 4,000 residents, it is the centre of the world for us. After all, with more than 1,300 employees spread across our global installation locations, we are one of the leading manufacturers of milling machines.

If we have piqued your interest and the thought of working for a machine manufacturer appeals to you, there are several ways in which you can acquaint yourself with our company. An internship gives you the chance to get to know the job of an apprentice or trainee at HERMLE for a short period of time and to gain real professional experience. Our various apprenticeship programmes and study programmes allow you to get to know our company’s processes in detail. Our workforce encompasses a diverse array of specialists, from engineers and IT professionals to commercial experts in wholesale and foreign trade management. Be it apprenticeship or study course – discover which career suits you best.

Humans are not machines. And that is why it is all about the ‘we’ at HERMLE. We seek individuals who are passionate, dedicated to their job and have a vision for the future. It really is of great importance to us. Since we also have a vision – a vision for the future of machine factories. Beyond our products, it is the uniqueness and special quality of our team that resonates with global customers. Shape the future with us.

Buy HERMLE milling machines – with peace of mind

These are the facts. You now know exactly what our machines are made of and what their benefits are. So, let us take a look at the general conditions: If you are looking to buy a milling machine, the price is predominantly based on your specific requirements – i.e. the actual scope of performance. The final price of your machine solution is influenced by certain variables, such as the number of axes – 3-axis or 5-axis – and the assortment of spindles and accessories. To pick the ideal CNC milling machine that is perfectly tailored to your production parameters, it is imperative to precisely define your requirements. What should the machine be able to do? And which additional functions can you do without or never need?

Once you have addressed all these questions, we will work together to deliver a bespoke automation solution tailored to your production project – guaranteed.Aligned perfectly with your service offerings, the milling machine reliably machines workpieces of various materials to the highest quality along the X axis, Y axis and Z axis. This will not only save you time but also deliver flawless results, thereby making a good lasting impression on your customers. As a leading manufacturer of CNC milling machines, we guarantee: “Milling at its best” with HERMLE. If you are interested, please get in touch with a member of our team, they will be more than happy to help and advise you.

About the enormous capabilities of CNC machine tools

CNC machines are machine tools that automatically fabricate workpieces with complex geometries. The term CNC means computer numerical control, which refers to the automated control of machine tools. Thanks to the advanced control technology of CNC machine tools, achieving the highest precision standards is possible throughout the entire production process. Previously, machining basically depended on how the operator was feeling that day – today, quality assurance is entrusted to computers, thus ensuring a top quality finish all the time. CNC machines are primarily used for chip removal processes, e.g. milling, using products like portal milling machines or special machines.

Needless to say, the hardware alone – the machine – is not enough for fully automated machining. It also requires software that interprets information and commands to stipulate machine actions. This software is the actual CNC program.CNC programs typically comprise data that precisely defines the outcome of the machining process. Entire data records specify each work step individually and check whether the instructions are being executed accurately by the machine. Tailored controls designed for specific applications enable the precise milling of intricate shapes across a diverse range of product materials.

The main advantage of this technology: Due to universalised CNC programs, milling machines from various companies can fabricate the same end product. The collaborative use of CNC programs is, therefore, crucial for modern manufacturing techniques - the key concept here is outsourcing.

Much more than a conventional milling machine.

Conventional milling refers to the manual machining of a workpiece along the horizontal X axis and vertical Y axis, for example on a standard lathe. While this method enables the universal production of complex components as mass products, it is not only complex and labour intensive but also time consuming. Workshop productivity is much lower than it should be. Companies therefore usually use CNC machines instead of conventional milling machines for their production processes. CNC milling machines operate in a fully automated manner and ensure continuous operation at an unwavering high level of precision. Operators no longer have to perform each milling step manually, but simply need to set the required CNC program. Operators can directly manage settings, configure machining parameters and make adjustments via a digital display on the machine. Three-dimensional machining of the workpiece proceeds swiftly and reliably in the background, employing various tool attachments, spindles and optional accessories on all three to five axes Operators can be strategically deployed to areas where their skills are needed most.

In the meantime, the market offers a plethora of CNC machine options: But at HERMLE, we remain true to our guiding principle of “milling at its best”. And to keep this promise, each of our models is characterised by various strengths. This means your workshop is equipped with high performance machines and machining centres that are perfectly tailored to your needs and goals.