Technical Data

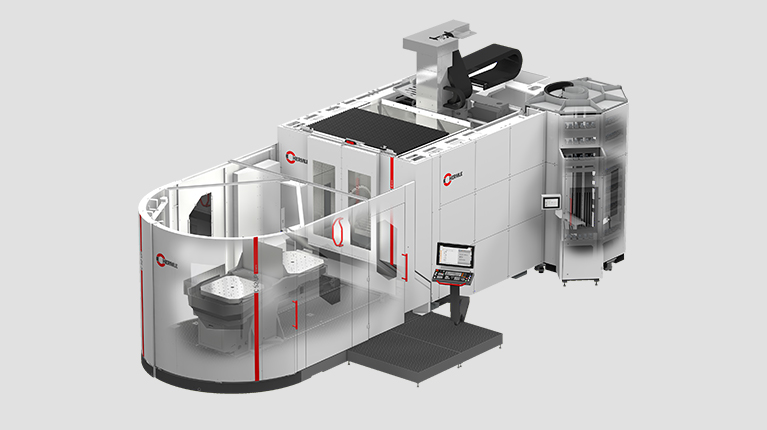

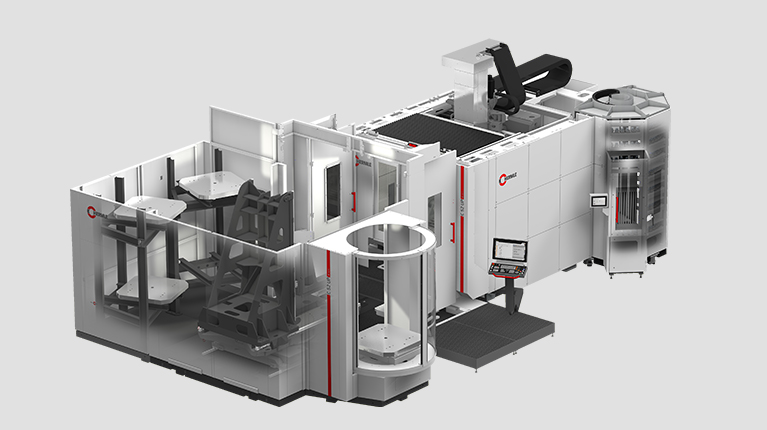

Dimensions

-

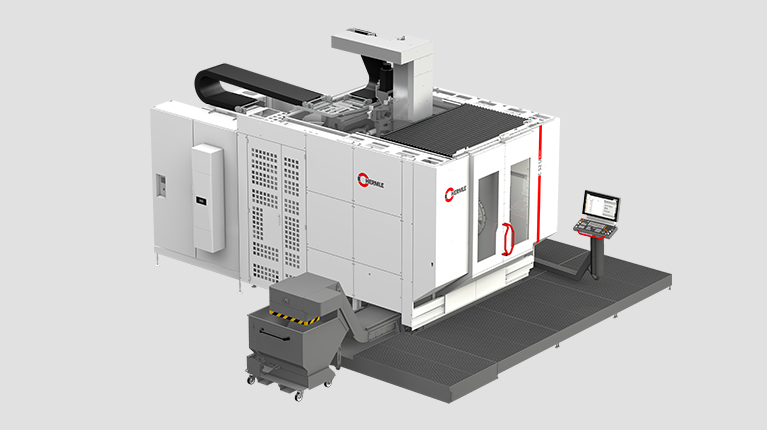

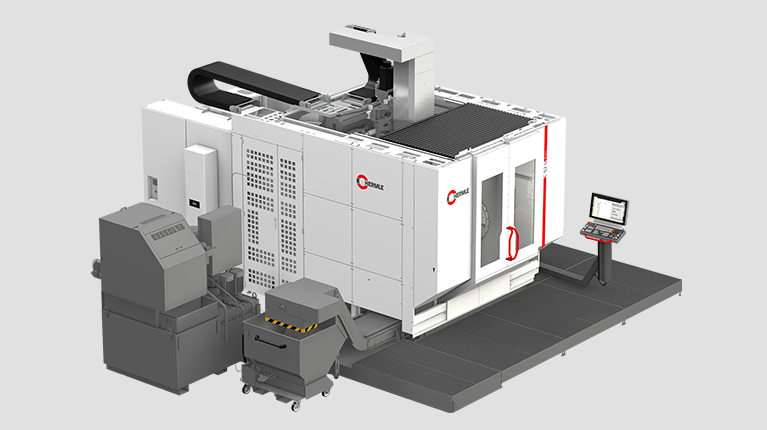

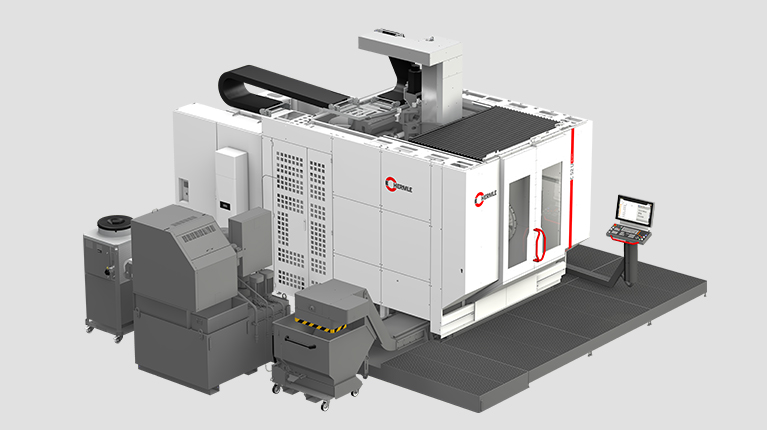

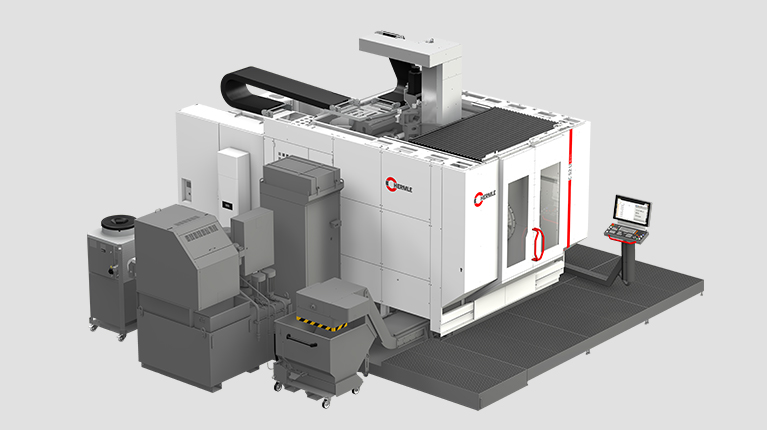

Traverse path: 1000 x 1100 x 750 mm

-

Body: Ø 1100 / H 810 mm

-

Collision circle: Ø 1290 mm

-

Vertical table clearance: max. 950 mm

Facts

-

Rotational speed: 9000/14000/18000 1/min

-

Rapid traverse linear X-Y-Z : 60–60–55 m/min.

-

Swivelling rotary table: ø 1000 mm

-

Max. table loading: 2000 kg

Applications

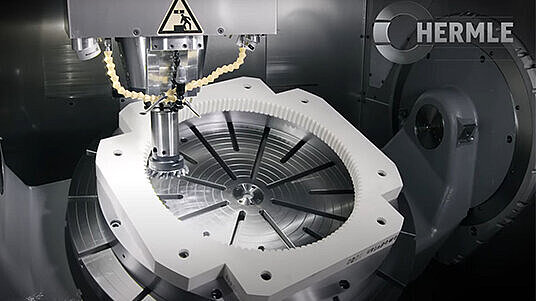

C 52 U MT | Machine construction | Power skiving

HERMLE C 52 U MT dynamic in 5-axis mill-turn version. Machining using power skiving in obomodulan for machine construction

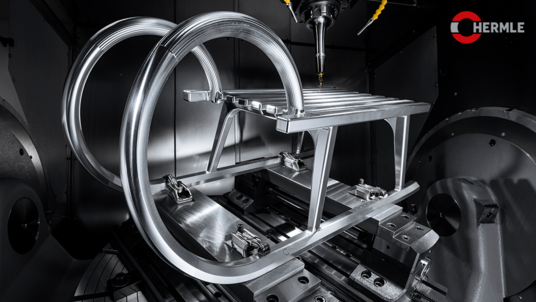

C 52 U MT | Machine construction | Pelton wheel

HERMLE C 52 U MT dynamic in 5-axis mill-turn version. Machining a Pelton wheel in 1.2312 for machine construction

C 52 U MT | Sports and leisure industry | Sledge

HERMLE C 52 U MT dynamic in 5-axis mill-turn version. Machining a sledge in AlMg4.5Mn for the sports and leisure industry. Workpiece measurement using Renishaw Sprint touch probe.

User reports

When taking a risk achieves positive outcomes

BRAVO-TECH BVBA

Contract manufacturing

BRAVO-TECH is now a successful contractor based in the Belgian town of Oudenaarde. The company mills, deburrs and polishes moulds for hard-top cases, blades and turbine wheels for compressors and pumps, as well as engine components such as camshafts and crankshafts.

Open and honest, but without the show

Zerspanungstechnik Mangner GmbH

Contract manufacturing

Zerspanungstechnik Mangner chooses quality over loud marketing. The company owner now provides us with a rare glimpse inside the production facility. Nine 5-axis machining centres from Gosheim make up the bulk of the machinery. With them on its side, Mangner is sure it can live up to its delivery promises.

In future: even more complex

Toolcraft AG

Aerospace

Anyone who dares to combine additive manufacturing with precise machining clearly loves complexity. toolcraft uses both technologies and has been able to astonish its customers with hitherto unknown quality levels. Hermle's thought-through machine design plays an important role here.