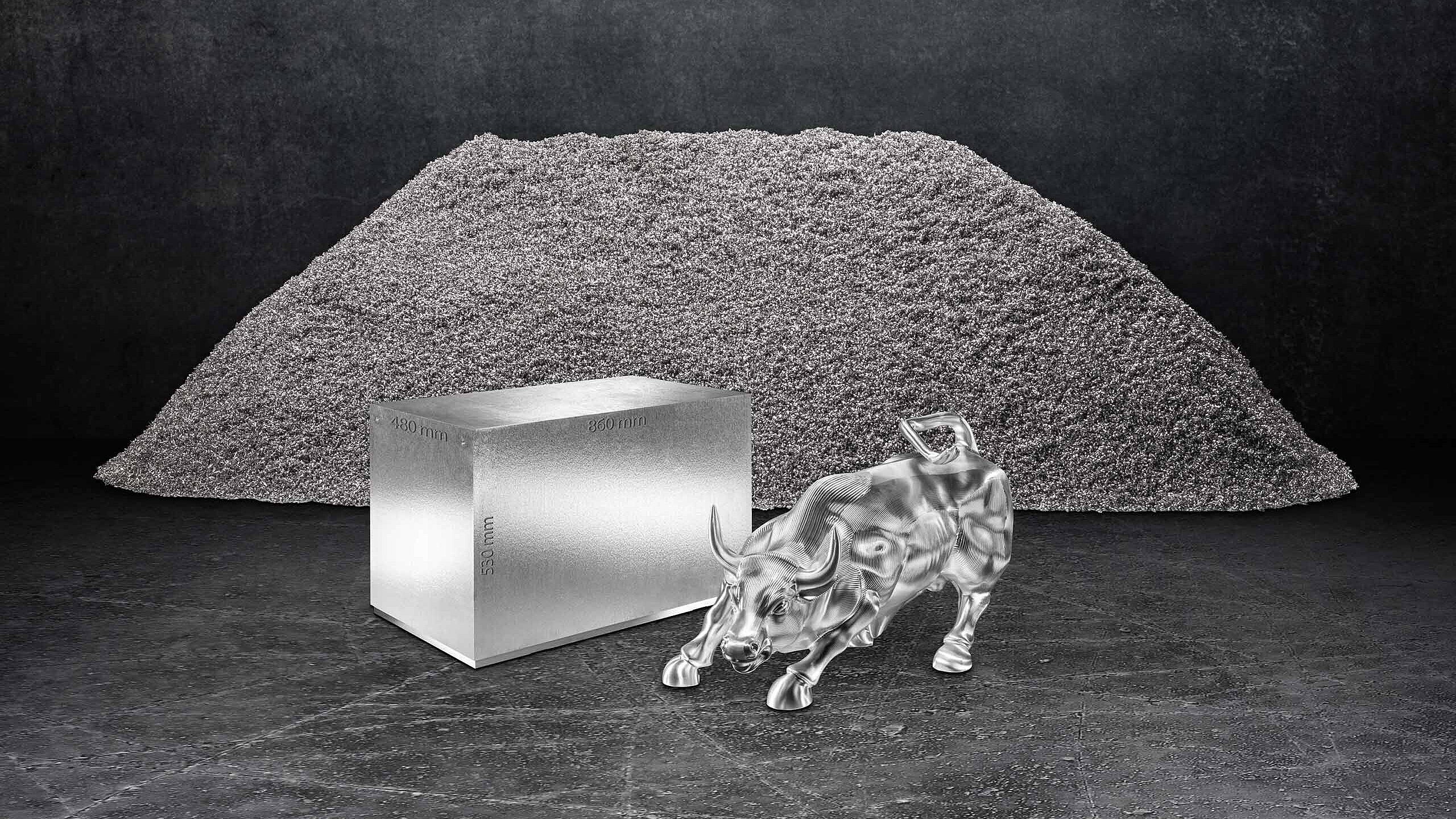

“Fritz the Bull” and “Ben the Bear”

-

“Fritz the Bull” made of aluminium -

“Ben the Bear” made of black POM, during machining -

“Fritz the Bull” 109 kg, blank 600 kg, and 500 kg of chips (3.5 m3)

After the bull "Fritz" already caused a sensation at the IMTS and numerous visitors had their photo snapped next to the spectacularly presented animal, “Fritz” now has a buddy: the bear "Ben". They make a great pair, because together they are the symbol of the ups and downs on the stock exchange. This will make them a perfect eye-catcher for Hermle as a stock corporation in the Hermle showroom in the future.

The bull was milled from solid material on a 5-axis machining centre C 650 from an aluminium block (W x L x H 860 x 480 x 530 mm with a weight of 600 kg). The challenge in this complex 5-axis simultaneous machining task is to turn the blank in the working area of the C 650 (X-Y-Z 1050 x 900 x 600 mm) in two axes (interference area 1100 mm) and to swivel and machine it collision-free (swivel range +/-115°). In particular, collision monitoring in interaction with dynamics and milling strategy requires complex specialist knowledge and good programming skills on the part of the operator. After machining, the finished bull weighs 109 kg. Machining took 35 hours and produced 3.5 m3 of chips.

The bear, on the other hand, was milled from solid material on a 5-axis machining centre C 42 from a block of black POM (W x L x H 400 x 150 x 230 mm). Polyoxymethylene, POM in short, is a high-molecular thermoplastic plastic. For its high rigidity, low friction coefficient, excellent dimensional stability and thermal stability, it is used as a technical synthetic primarily for precision parts. The bear was programmed using OpenMind. Its structure is based on an STL model which generates a 3D contour from a multitude of triangles.

Both workpieces are classical “show parts” and would certainly not be manufactured under economical aspect. However, they impressively showcase the efficiency of the Hermle machining centres. These "show parts" have already been used repeatedly for marketing purposes and always get high click rates on Youtube and Vimeo.

Contact details for journalists/editors:

Maschinenfabrik Berthold HERMLE AG / Marketing Department / Email: marketing@hermle.de / Phone +49 (0)7426 95-0

78559Gosheim