Cleverly decoupled for maximum efficiency

AMAG components Karlsruhe GmbH relies on automation: Pallet changer PW 3000 replenishes the 5-axis machining centre C 62 UP. Ever since the subcontractor separated machine setup from the actual machining process, there has been a significant and noticeable increase in spindle runtime and productivity.

It has to be light – as the workpieces are generally used in the aerospace industry. Blocks of solid metal are transformed into delicate, yet high-strength components. “We mainly machine aluminium and titanium for our customers,” says Volker Manz When it comes to milling the high-performance materials, the production manager at AMAG components Karlsruhe GmbH relies on high-performance machines. “For us, it is immensely important that the machining centres are reliable, can be used flexibly and, of course, enable precise milling operations,” he says, when summarising the requirements. In recent years, the company has gained extensive experience with several HERMLE 5-axis machining centres, such as the C 30 U, C 40 U and C 62 U. “We needed additional production capacity for large workpieces up to 1,300 mm and therefore decided to purchase a second C 62, this time as a UP variant.”

Known previously as Aircraft Philipp Karlsruhe GmbH, AMAG components has been wholly owned by the Austrian company AMAG Austria Metall AG since 2022. The corporate group has thus extended its value chain. Thanks to its extensive recycling expertise, AMAG can reprocess metal waste, such as that generated during component production at locations in Germany, into high-quality rolled products at its plant in Ranshofen, Austria. Besides saving valuable raw materials, this closed loop requires 95% less energy than primary production.

Smart functions

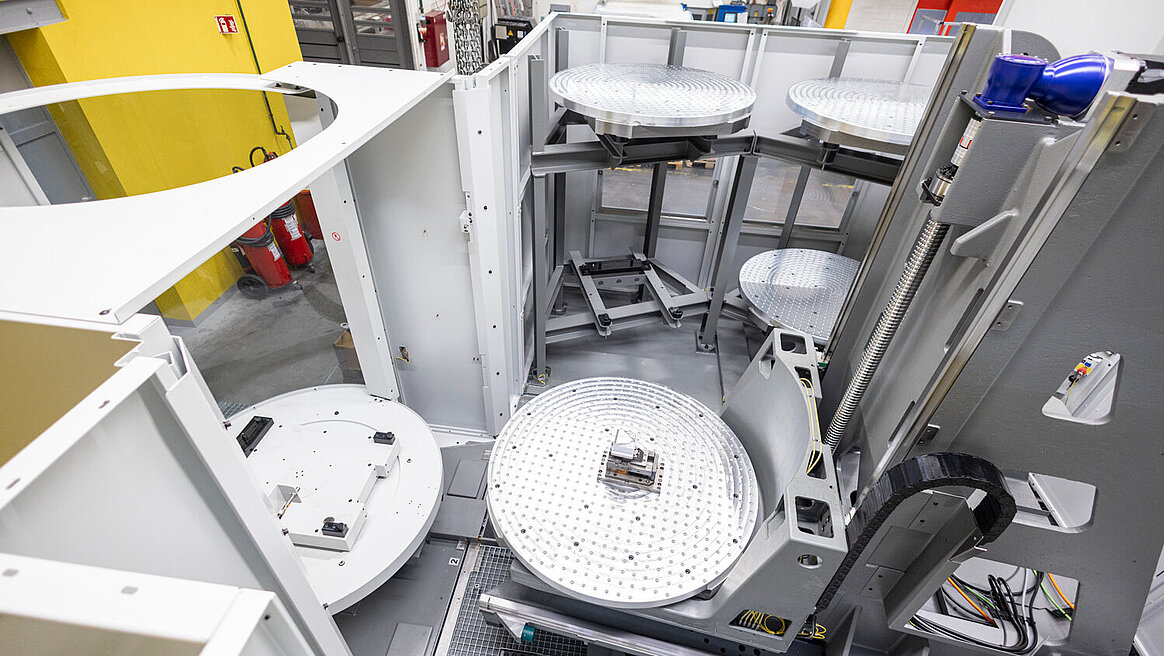

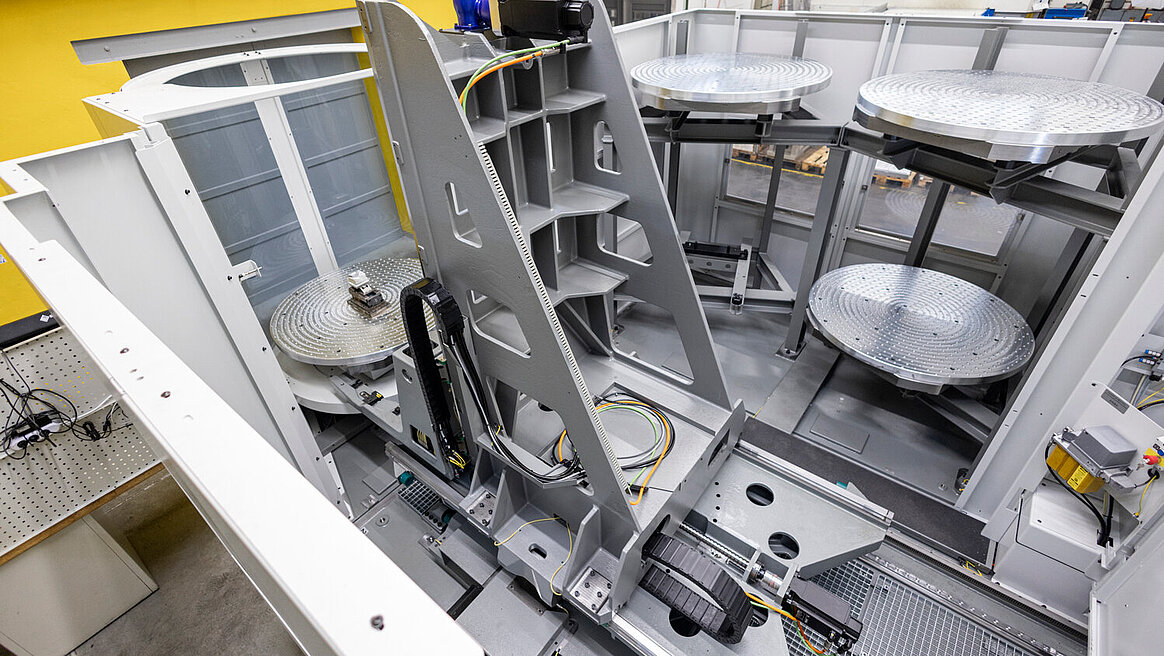

Every detail counts in the aerospace industry. AMAG components therefore leaves nothing to chance. ‘First time right’ is more than just a guiding principle here, it is a commitment. Latest example: The 5-axis machining centre C 62 UP dynamic, which uses touch probes and tool breakage monitoring to guarantee automated production of the highest quality. “So far, we have used the measuring system less actively on our other machines,” explains Volker Manz. The wear-free, optoelectronic probe aligns the component virtually to achieve perfect results even when the clamping is not precise. “This provides us with a very high level of process reliability and eliminates the need for machine operators to move or reposition the component,” says Volker Manz when describing one of the major advantages. To utilise the full potential of the machine, AMAG components employs the pallet changer PW 3000, which is ideal for large and heavy loads weighing up to 3,000 kg.

-

CNC miller Jonathan Gabel appreciates the flexibility offered by the pallet changer. It allows him to prepare several components at once. -

CNC miller Jonathan Gabel appreciates the flexibility offered by the pallet changer. It allows him to prepare several components at once. -

The PW 3000 provides space for four pallets – and decouples setup time from main time. -

The PW 3000 provides space for four pallets – and decouples setup time from main time. -

The C 62 UP dynamic with the connected pallet changer PW 3000 decouples setup time from machining time, thus significantly increasing productivity.

Full control

The PW 3000 is controlled by the intuitive management software HACS (HERMLE Automation-Control-System). Before commencing an order, the intelligent software automatically performs the most important checks: Have the zero points been loaded? Is the pallet in the system? And of course – are all the required tools available? If something is not quite right, the operator is immediately informed in real time.

Like all the machines at AMAG components, the C 62 UP is also connected to the in-house Factory Operations Monitoring system. It allows employees to closely monitor machine statuses at all times and to respond quickly should it ever become necessary. “We can manufacture 24/7, but usually have the weekends off,” claims Volker Manz. “We want to be an attractive employer for our workforce – and automation obviously helps us achieve this goal.”

Closed material loop

It takes several hours to machine a component – the C62 UP removes up to 90% of the original material. The necessary flexibility is guaranteed by 70 tools located in the machine, which are complemented by another 135 tools in the additional magazine ZM 135. “For example, when we mill hinges from a block of metal, the machine has to remove a lot of material,” explains CNC miller Jonathan Gabel. The chips are subsequently washed, dried and compressed to form briquettes. “This makes us part of the AMAG value chain,” says Volker Manz More precisely, this means that the subcontractor in Karlsruhe obtains the material from its parent company, which then carefully reprocesses the chips back at the main plant.

Delivery of the new C 62 UP was precision at its finest. “Our workshop doors are low – HERMLE had to partially dismantle the machine to get it inside the building,” recalls Volker Manz. “Getting it in there really was a precision job. Nevertheless, delivery and installation by HERMLE went smoothly and according to plan.”

Flexible staff deployment

The C 62 UP with connected pallet changer has been up and running since November 2024. Can any conclusions be drawn yet? “Thanks to pallet handling, we are countering the shortage of skilled labour, as we can now plan and manage tasks and their distribution much better,” says a delighted Volker Manz. The workforce also appreciates the smart system. “We asked who would be interested in taking responsibility for the C 62 UP and received several applications. The machine is very popular.”

Maintenance manager Michael Jakob agrees: “Machining is carried out on four HERMLE machines, one of which has been in use for over 20 years. The after-sales service is exemplary, and I am totally satisfied with the performance and reliability of the systems.” In the unlikely event that something does go wrong, HERMLE usually sends the necessary spare parts on the same day as the error message. “Depending on the severity of the problem, the matter is dealt with by the next available technician, which helps keep downtime to a minimum.”