Greater capacity, greater flexibility and absolute precision. Thanks to its new investment in HERMLE, Mestdagh will now be able to produce autonomously around the clock and deliver unrivalled results to its customers.

Mestdagh, a Roeselare-based specialist in precision mechanical components, is shaking up the industry with a bold investment:

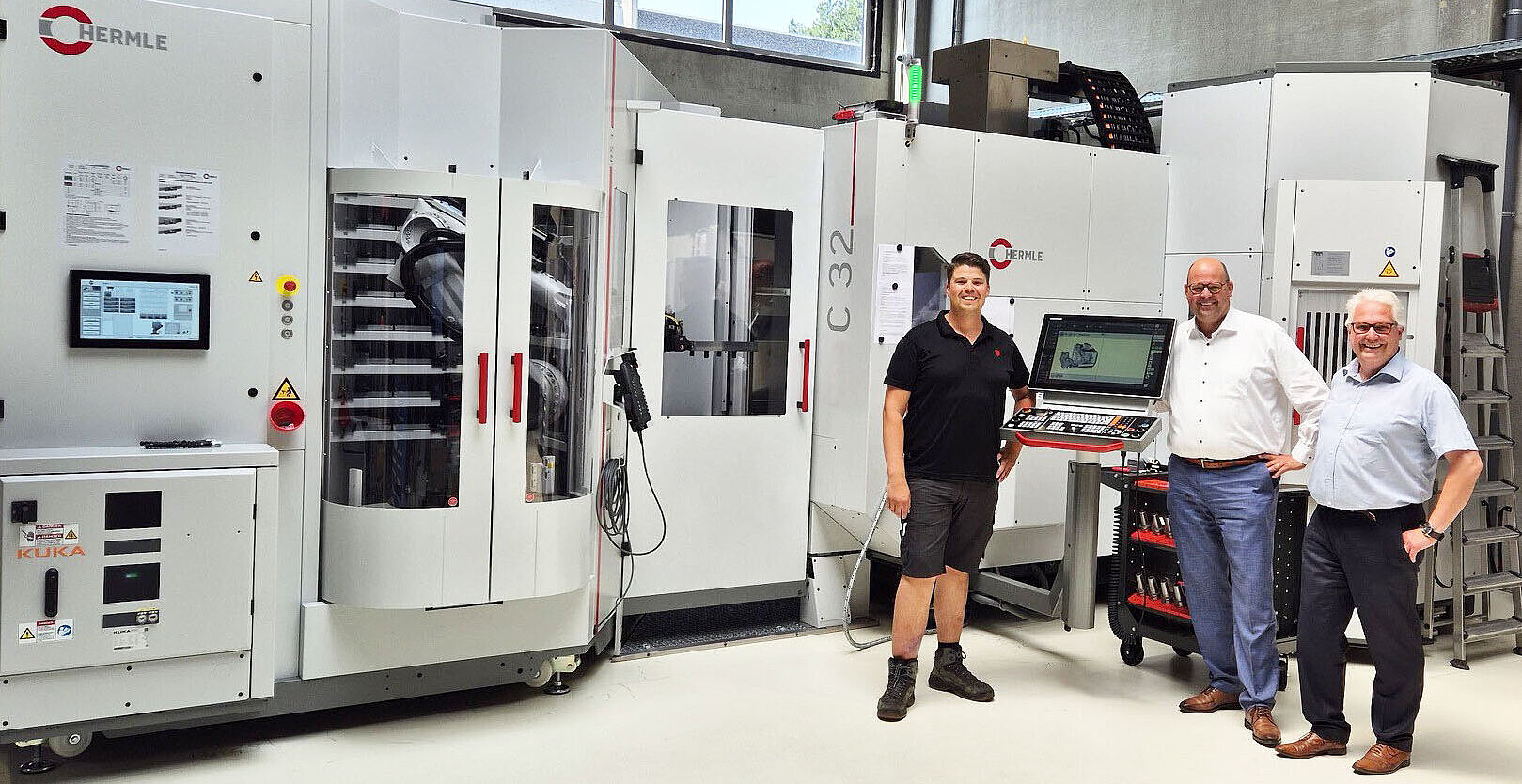

it is the first company in Belgium to install the latest generation of HERMLE with a robot cell. This is an absolute world first and a decision that goes beyond technology.

Even shorter throughput times, greater reliability and maximum flexibility in production – that's what it's all about. Mestdagh not only wants to respond to today's needs, but also be prepared for tomorrow's challenges.

The focus is on the HERMLE C 32 GEN2, a state-of-the-art 5-axis machining centre that can machine complex parts with extreme precision and efficiency, taking both the capacity and quality of production to an even higher level.

The system is equipped with the latest technologies and enables Mestdagh to deliver an excellent and consistent end result, regardless of the scope of the project.

‘Together, we set the tone in the market: our collaboration illustrates how innovative technology and entrepreneurship reinforce each other.’

– Geert Cox – Managing Director, HERMLE Netherlands

Pioneer in the industry

At the heart of this innovation is the combination of the HERMLE C 32 GEN2 with the RS 1 robot cell. While the machine itself ensures unparalleled precision and stability when milling complex parts, the integrated automation enables a completely new way of working. The robot cell enables autonomous production around the clock without compromising on quality. In addition, the automatic changeover between workpiece handling and pallet loading allows for quick changes between orders.

The result? Speed, flexibility and the ability to produce individual parts and small batches as well as larger series with the same care and precision.

‘For us, it's not about the technology itself, but about how we can serve each customer even better and faster. That's why we continuously invest in refining our processes and optimising our working methods,’ explains Managing Director Erik Mestdagh. ‘Precision and efficiency are simply in our DNA. In HERMLE, we have found the ideal partner to further realise this.’

Geert Cox, Managing Director of HERMLE Netherlands, adds: "It is something special that the first installation of the HERMLE C 32 GEN2 with RS 1 automation in Belgium is at Mestdagh.

The trust they place in our technology confirms our shared ambition to install the first HERMLE C 32 GEN2 machine with RS 1 automation in Belgium at Mestdagh. The trust they place in our technology confirms our shared ambition to push the boundaries in the precision engineering industry. Our collaboration shows how innovative technology and entrepreneurship reinforce each other and how we are setting the tone in the market together.

The future is exciting...

This is more than an innovative milestone: it is a statement of entrepreneurship and leadership. ‘We want to become the benchmark as a precision engineering supplier. Investments in advanced technologies are crucial in this regard, but they must also translate directly into tangible added value for our customers. We are now fully operational and are seeing the positive effects on our daily operations and customer satisfaction. In short: the future is exciting!’ concludes Erik ambitiously.