Permanent precision

The subcontractor Fischer CNC-Technik has been relying on machining centres from HERMLE since 1998. Why? Small footprints, maximum precision and intuitive axis systems impress the entire workforce. Today, the company is scaling up its automated production thanks to a combination of the C 42 U and HS flex heavy, enabling unmanned machining during the night and at weekends.

“I’ve been a big fan of HERMLE machines for a long time, so I’m obviously a bit biased,” reveals Frank Lichti, customer advisor and head of work preparation at Fischer CNC-Technik GmbH. Fischer CNC has been using the machining centres from Gosheim since 1998. The machine park has, in the meantime, grown to 16 machines, including four C 800 U, eight C 600 U, one C 40 U, two C 22 UP with PW150 and, since last year, the new C 42 U with the handling system HS flex heavy. “Ever since we started working with the first machine almost 30 years ago, my expectations have been exceeded time and time again. Even our oldest C 800 U still meets the original acceptance requirements to this day.”

Fischer CNC-Technik was founded in 1985 in Neustadt an der Weinstraße as a subcontractor and today employs around 50 people. The goal: Outstanding quality and components machined to an accuracy of one thousandth of a millimetre. Since 1997, Frank Lichti has been managing director and shareholder of the company alongside three partners. In 2017, they sold the company to HÖR Technologie GmbH based in Weiden, a developer and manufacturer of complete gearboxes, among other things. “Since then, our product range has shifted slightly. While aluminium used to account for around 80 percent of our raw materials, roughly 60 percent of what we now machine is highly tempered and hardened steel,” says Lichti. The company also uses HERMLE machining centres to machine titanium and plastics such as PEEK. Many of the products are used in the automotive industry. They include technically advanced components such as oil pumps, shift forks, high-performance electric motor housings and gearing components.

Why one when you can have two?

Fischer CNC-Technik initially relied on machining centres from another German manufacturer. “We were not dissatisfied with them,” recalls Frank Lichti. However, when it came to significantly increasing production capacities in 1998, HERMLE stood out in one particular area: The small footprint required by the systems. “We only had one workshop, and there was room for two machining centres from Gosheim in the same space where I could have set up just one machine from a competitor,” explains the former managing director. “The C 600 U and C 800 U are the most compact systems that HERMLE has ever built.”

Another key factor in the decision was the clear axis system principle: Three axes in the spindle, two axes in the machining table – an easy-to-understand design. “The combination of the swivelling rotary table and the centrally positioned rotary axis is extremely user friendly,” Lichti remarks.

User-friendliness is also the key reason why Fischer CNC-Technik is now focussing on automation with HS flex heavy. “Twenty years ago, three shifts were the norm, with qualified employees managing fifteen machining centres every night, clamping parts and setting up machines,” recalls Frank Lichti. “Today, we can no longer find employees who are willing to work these hours.” Thanks to automation, the company can now operate unmanned during these periods and at weekends. “We need to achieve higher productivity with the same workforce. To achieve this goal, we must enhance efficiency and streamline operations. We can only accomplish this in two-shift operation through automation.”

-

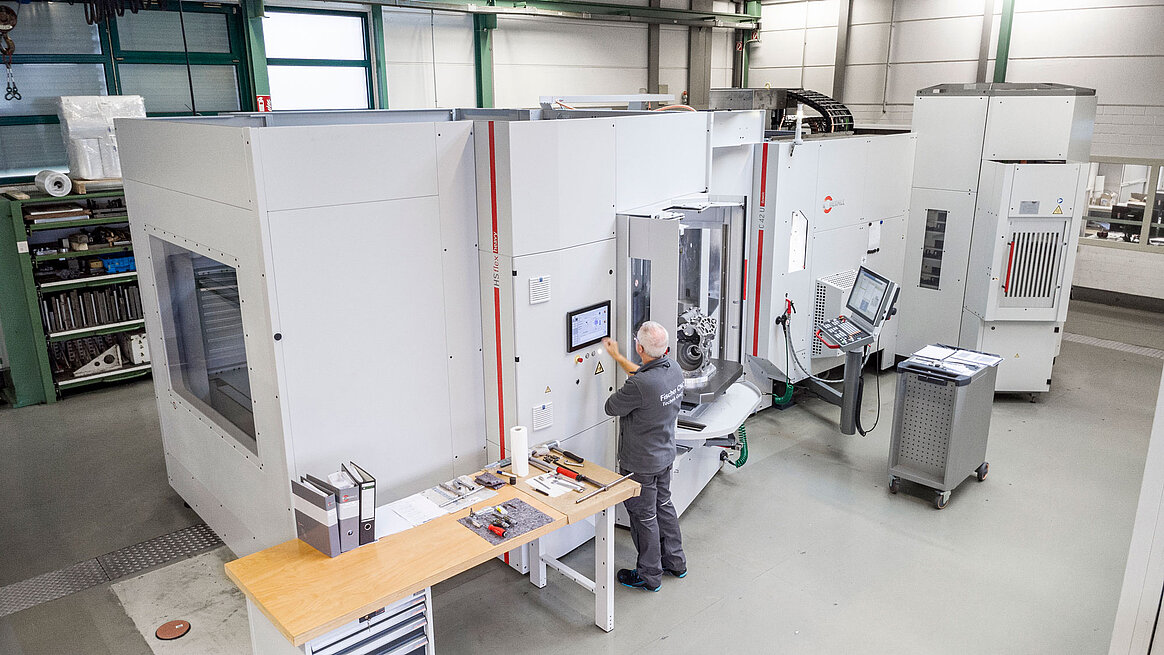

The handling system HS flex heavy perfectly meets varying production requirements. -

The machine offers a high level of accessibility for manual tasks and maintenance. -

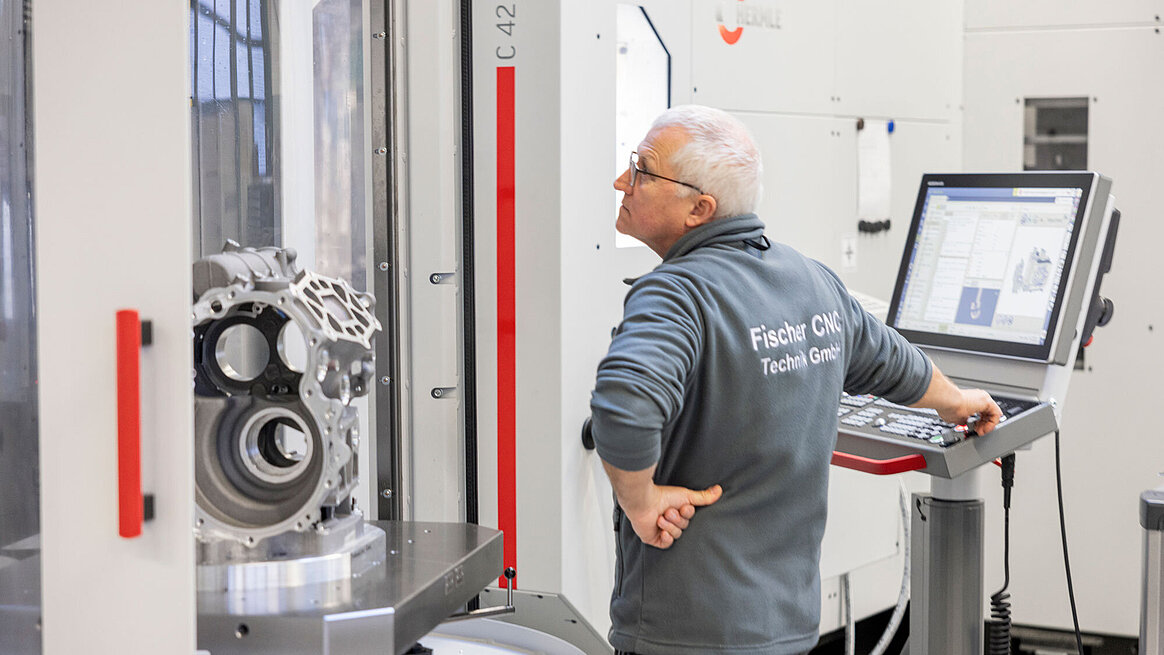

The handling system HS flex heavy perfectly meets varying production requirements. -

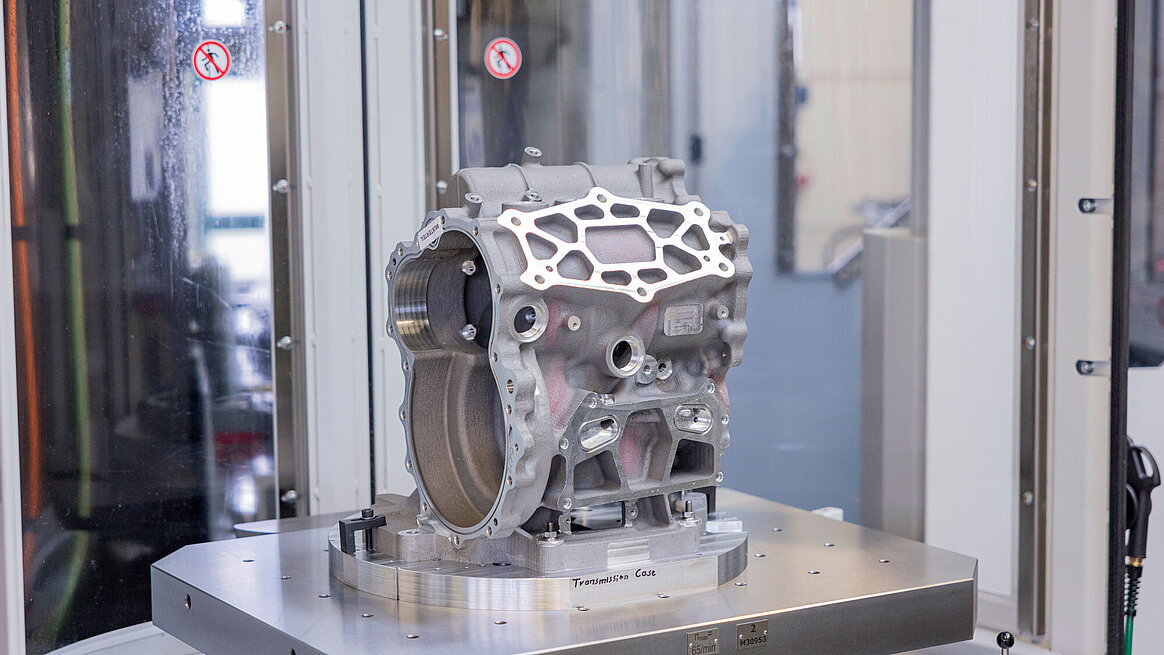

Fischer CNC-Technik produces many parts for the automotive sector, including gearbox housings for its parent company HÖR Technologie. -

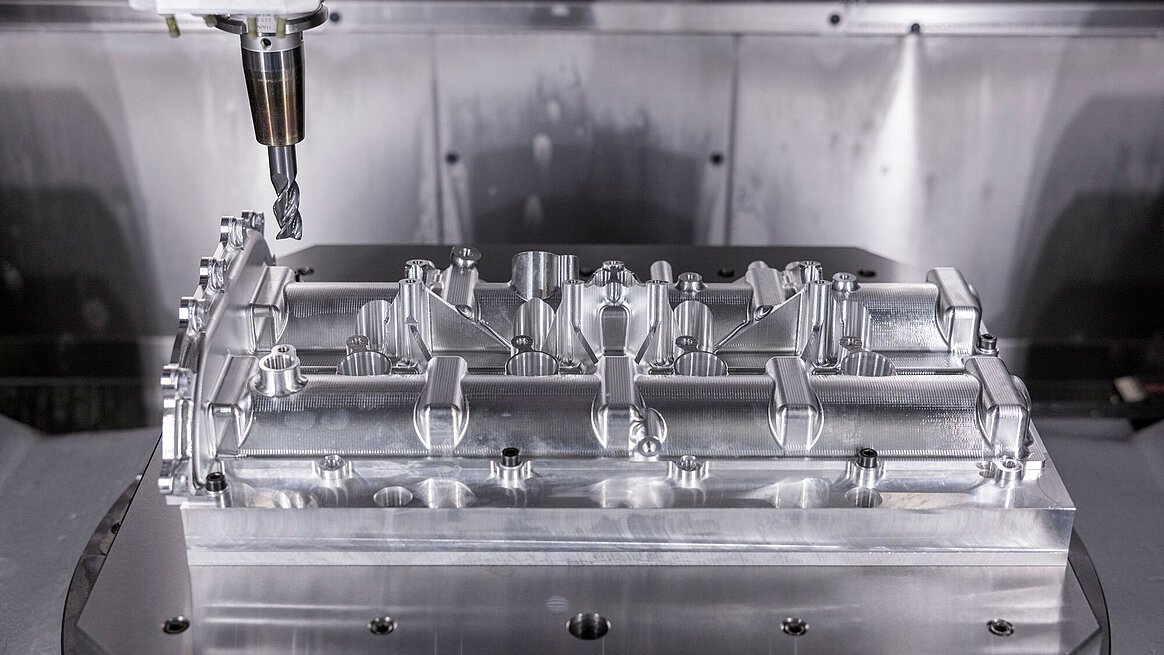

Complex components such as this cylinder head cover are part and parcel of the subcontractor’s daily tasks. -

Everything in view: The system is characterised by excellent accessibility to all components.

Small batches, heavy weights

The handling system HS flex heavy processes various formats without any restrictions. Unlike conventional pallet changers, it can be docked to all HERMLE machines and supports modular expansion. The solution follows the “high mix, low volume” principle and perfectly meets varying production requirements. A typical batch size at Fischer CNC-Technik comprises five or more components. The company employs various load carriers to reduce collision contours and maximise pallet density per square metre. “Given our workpiece specifications, we chose the ‘heavy’ version with 17 pockets,” explains Lichti. This allows the subcontractor to also automatically handle components weighing up to 1,200 kg, with some clamping operations lasting several hours. The entire mechanics and the transport system are generally reinforced to withstand the high loads. Naturally, the handling system with the storage modules provides ample space for large and heavy workpieces.

The HACS software controls the automation process via a dashboard. HACS stands for “HERMLE Automation-Control-System” and automatically checks zero points, pallet positions, machine setup and tool availability. In the event of faults, operators receive real-time notifications.

One decade of automation

Fischer CNC-Technik first experienced HERMLE automation back in 2015 with two C 22 UP compact 5-axis machining centres featuring an adapted pallet changer. “They are great machines, but the short Z traverse path is a drawback,” Frank Lichti claims, despite being a loyal HERMLE fan. “But the C 22 remains ideal for our compact precision parts.”

The PW150 pallet changer offers space for eleven pallets and allows main-time parallel setup. The rotating setup station offers a high level of user-friendliness. Thanks to the compact design of the PW150, qualified employees have unrestricted access to the machining centre. A double gripper transports the pallets between the setup station and the machining table.

High productivity, fast delivery times

The new C 42 U boosts automated production capabilities. Fischer CNC-Technik uses it to machine components measuring up to 800 millimetres in diameter and 560 millimetres in height. The system also produces complex geometries with utmost precision and reliability. “HS flex enables us to design all work processes efficiently and to minimise setup times,” emphasises Frank Lichti. The additional magazine ZM216 adds 216 tools to the machine’s 42, allowing a high degree of flexibility when machining diverse materials.

“Choosing automation was definitely the right decision,” Frank Lichti says. “Because we produce multiple prototypes and small series for customers who typically require them at very short notice. And we can only achieve this by making optimum use of the spindle hours.”