Thinking about the weekend

Cost pressure is constantly rising and with it the need to manufacture products as efficiently as possible. The subcontractor JEWA has therefore turned to automation – recently acquiring a RS 1 robot system from HERMLE, which supplies two adapted C 400 5-axis machining centres with pallets and individual parts.

Idyllically situated amongst the rolling wooded hills of the Spessart mountain range on the banks of the River Main, the small town of Kreuzwertheim is known for its half-timbered houses and historic alleyways. Since 1979, JEWA Metallverarbeitung GmbH has been based here in the Franconian region of Bavaria. The company specialises in the production of components for mechanical engineering. Edgar Jeßberger and Hermann Wagner founded JEWA in an old barn and moved to its current headquarters after just a few years in business. Today, JEWA employs 125 people and annually machines roughly 400 tonnes of raw material. The technology park continues to grow with new CNC lathes and CNC milling machines regularly being added, while the production area is constantly evolving. “When I took over the reins from my father back in 2016, we still produced milled parts in a very laborious way,” recalls managing director Thomas Jeßberger. “We were always strong when it came to turning, but our development in terms of milling was somewhat lacking.”

But that all changed after the arrival of the first 5-axis machining centre. JEWA acquired a C 22 U from HERMLE about ten years ago. “As a subcontractor, we require universal machines – from soft plastics to aluminium, titanium, tool steels and alloys, we machine everything across the board,” explains the graduate engineer. “The C 22 U is ideally suited for these tasks. And we were already well acquainted with the high level of precision provided by the machining centres from Gosheim.” The machine was delivered and installed on schedule. “Upon leaving, the haulier, who frequently delivers HERMLE products, said: “See you again in a year at the latest.” I was a little confused and asked him what he meant, as I definitely hadn’t ordered another system,” explains Thomas Jeßberger. “He said that, based on his experience with other customers and due to our machinery setup, he was quite certain that we wouldn’t stop at just the one HERMLE system. And he was right. Nine months later, he arrived with a C 22 UP and a wry smile.”

Systematic solutions and speed

JEWA invested in new 5-axis machining centres almost on a yearly basis. The first machine was followed by a C 32 U, a third C 22 U, a C 650 U and two C 400 U. The company now relies entirely on automation. For instance, the PW 150 pallet changer replenishes the C 22 UP. It allows main-time parallel setup and, thanks to the double gripper, can move 18 pallets weighing up to 250 kg, including the workpiece.

“As a result of a high-volume request, we needed a solution that could also handle individual parts – we therefore ordered the C 32 U and combined it with an automation system from Lang Technik,” explains the managing director. The advantage of this solution: “We were able to gradually introduce our employees to the concept of individual part automation, since nothing initially changes for them – they continue to clamp the workpieces as usual.” The robot grips the vise along with the workpiece and loads the machining centre. “The actual order never materialised, but the solution worked so well that we decided to have our original C 22 U converted for automated operation.”

-

JEWA swears by HERMLE – the company can therefore combine precision with high productivity. -

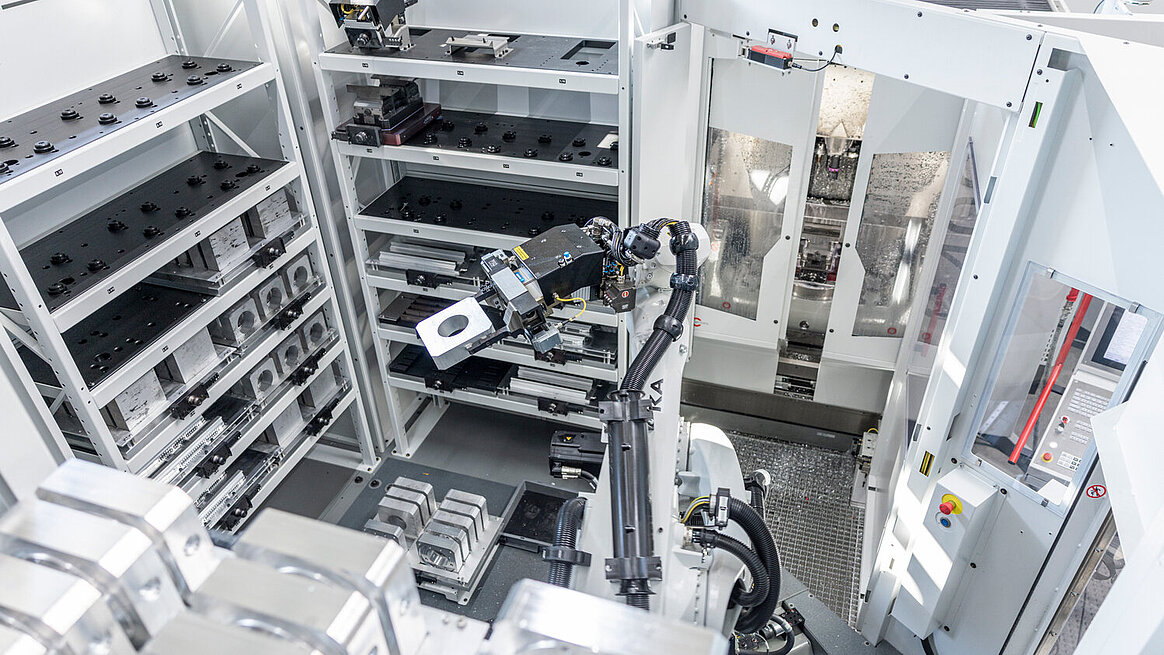

In the centre, the RS 1 robot system along with two adapted C 400 5-axis machining centres. -

CNC miller Max Schneider appreciates the high level of precision and ease of operation of the machine. -

Be it pallet or individual part handling – the RS 1 robot system adapts flexibly to the respective task. -

Be it pallet or individual part handling – the RS 1 robot system adapts flexibly to the respective task. -

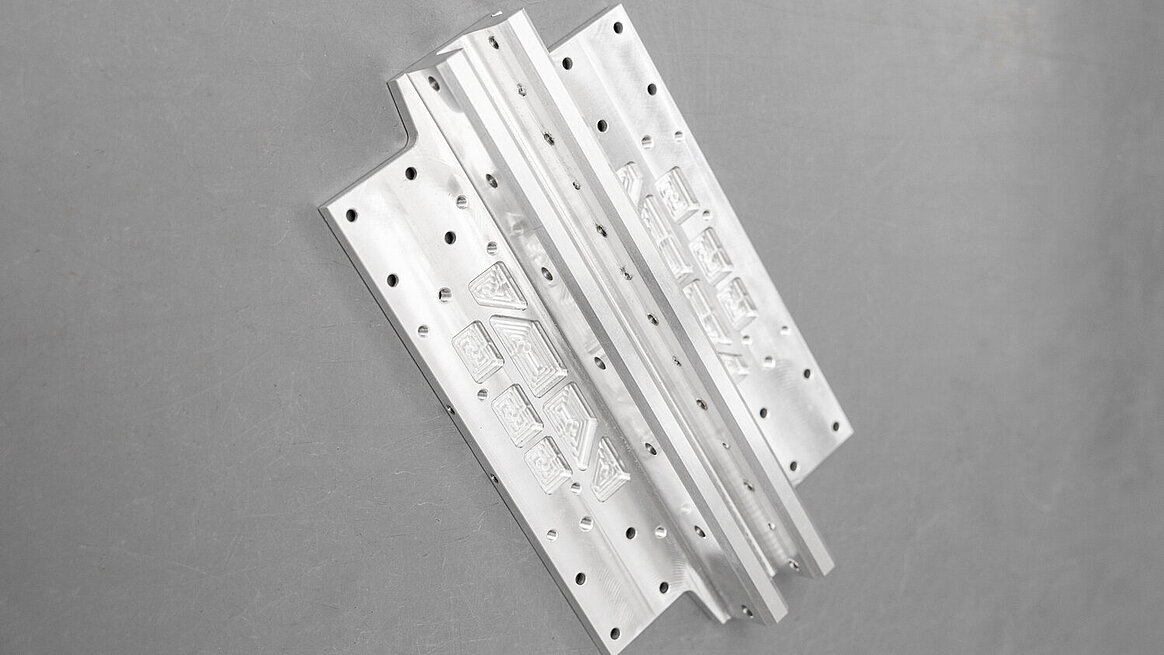

During the day, JEWA produces individual parts and small batches on the C 400; at night, the machining centre machines larger batches fully automatically. -

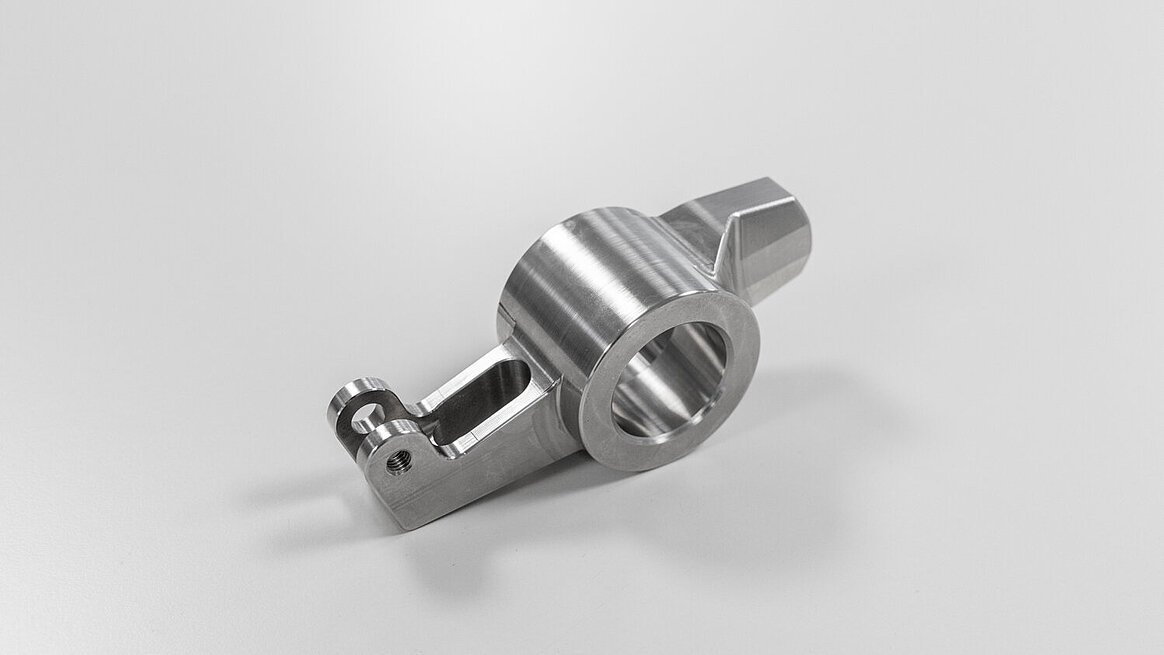

Highest precision – also when machining the 1000th component. -

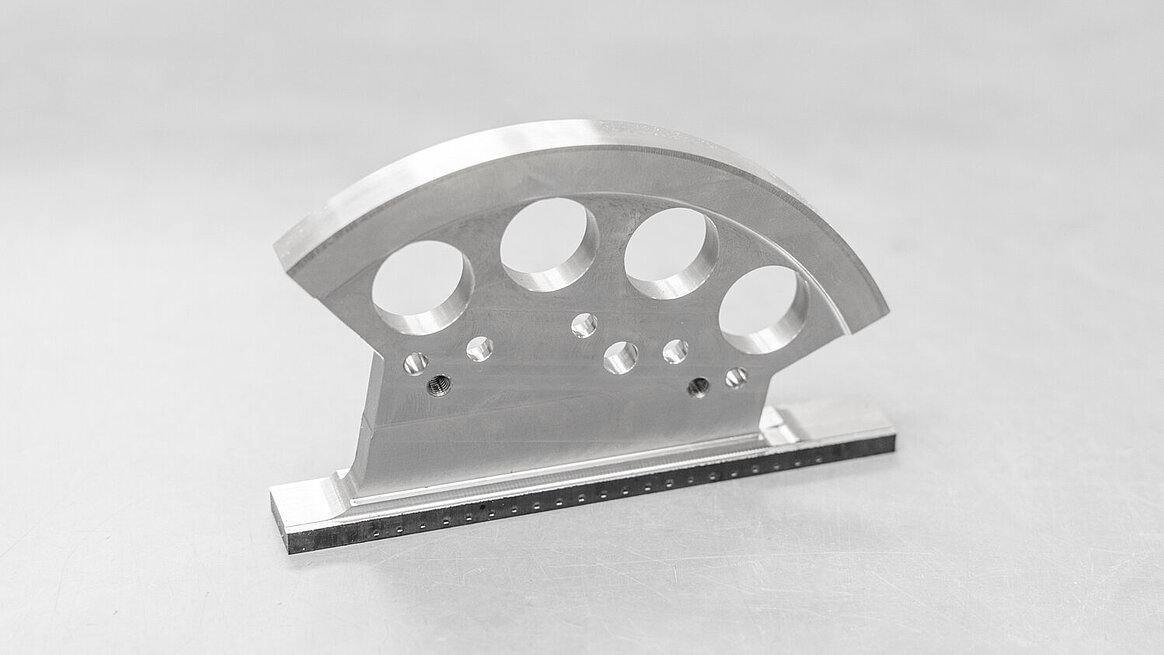

Precision in metal fabrication. -

Components measuring up to 650 millimetres in diameter and 500 millimetres in height can be produced on the C 400. -

The JEWA team: Thomas Jeßberger, managing director, Michael Baumann, production manager and Markus Herrmann, milling shop manager (from left)

Aha! moment with a big effect

What impressed Thomas Jeßberger most was the tripling of spindle runtimes – from 1,500 to 4,500 hours. “We operate in two-shift mode and saw automation as a great opportunity to add a third shift during the night. What we hadn’t considered at all during the planning phase was the weekend – but of course, our machining centres also enable unmanned production during this period.” The machines now run 24/7 – precisely, reliably, tirelessly.

There was a steep learning curve at first. “Our biggest challenge was chip and coolant management,” recalls Thomas Jeßberger. “Sometimes, the machine would stop after 36 hours because there was no coolant left.” At high speeds, large quantities of coolant are needed to machine aluminium. Luckily, a larger tank and a modified chip collector with double the capacity solved the problems.

From a single source

JEWA ordered the C 650 U 5-axis machining centre together with the adapted handling system HS flex. “It ensures flexibility in terms of clamping devices and setup times,” claims the managing director. Thanks to the automated handling of workpieces, the subcontractor has significantly boosted its productivity, as ancillary activities no longer impact spindle runtimes.

JEWA swears by identical systems and a standardised operating concept – and therefore by HERMLE. “We manufacture products for a multitude of customers and offer a huge portfolio of parts – from large quantities of simple workpieces to complex components in batch size 1. Thanks to the platform strategy, we can simply switch from one machine to another – depending on capacity utilisation and urgency.”

Know everything, do anything

Taking the next step towards the RS 1 robot system was therefore inevitable. “I watched a video of the system and knew that our production needed one. We were looking for a flexible solution – also for individual part handling. The RS 1 can do everything: It inserts pallets into the machining centre but also changes workpieces in dies.” In combination with two C 400 U machines, JEWA has found the perfect solution for handling its ever-changing range of jobs. “The machine is extremely compact for its working area and offers excellent accessibility. It meets all our requirements and complements our components perfectly – that was the deciding factor for us,” says Thomas Jeßberger. “When it comes to our machines, we need a jack of all trades. What matters most? Everything!”

That is the reason why the subcontractor usually acquires fully equipped machining centres. “There’s not much else to purchase,” he says, considering not just the advantages for the company but also for the employees. “Our employees can rely fully on the quality of the systems – so a sports car instead of a minivan. It’s not just the first and fifth workpieces that meet the requirements but also the five hundredth. When an employee prepares the machine for the weekend on Fridays, they know that they’ll find precisely machined parts in the drawer come Monday morning.”

Has the investment in the HERMLE machine park been worthwhile? “Definitely. Customers don’t purchase our products just because we’ve got some great machining centres. It’s all about quality, price and delivery periods. When it comes to quality, we are second to none, the precision of the HERMLE machining centres is outstanding. Thanks to automation, we can keep our prices competitive by reducing our hourly rates. And thanks to the third – unmanned – shift and identical machines, we are able to process all orders flexibly and thus consistently meet short delivery deadlines,” says the managing director when summarising his experience.