Technical Data

Dimensions

-

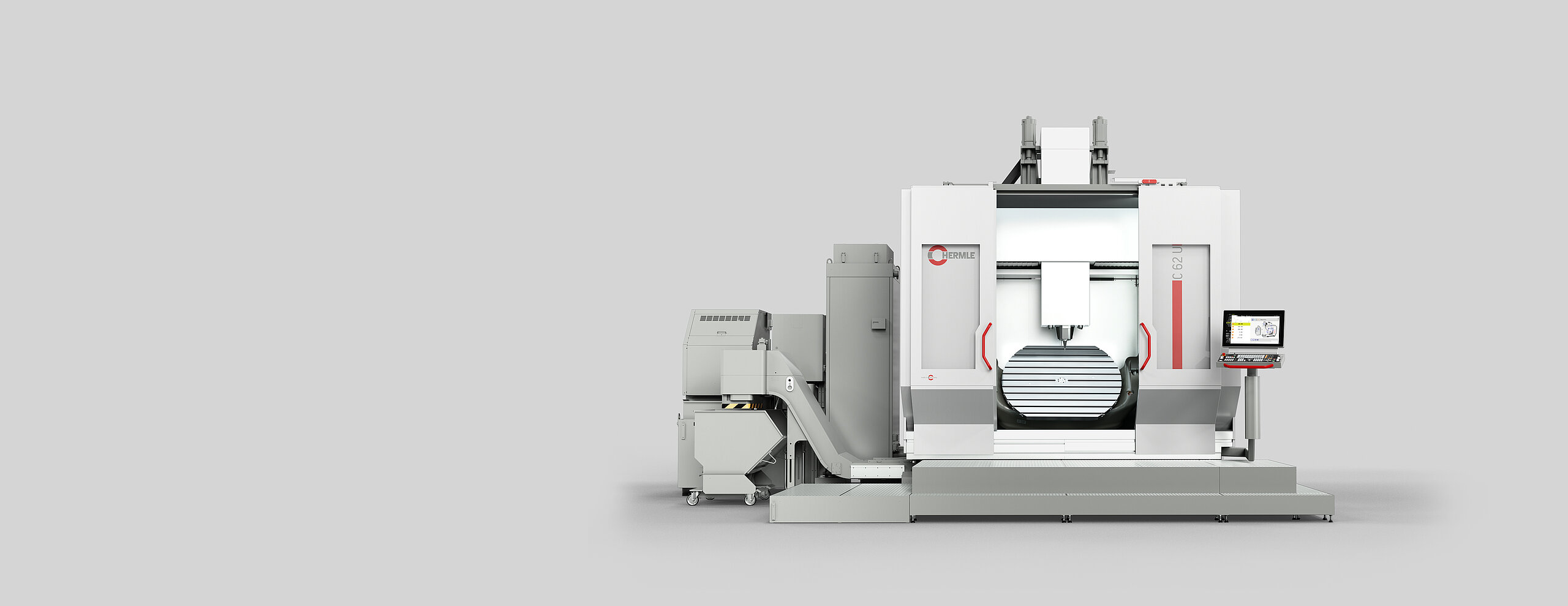

Traverse path: 1200 x 1300 x 900 mm

-

Body: Ø 1200 / H 900

-

Collision circle: Ø 1400 mm

-

Vertical table clearance: max. 1100 mm

Facts

-

Rotational speed: 9000/14000/18000 1/min

-

Rapid traverse linear X-Y-Z : 50m/min.

-

Swivelling rotary table: ø 1350 x 1100 mm

-

Max. table loading: 2500 kg

Applications

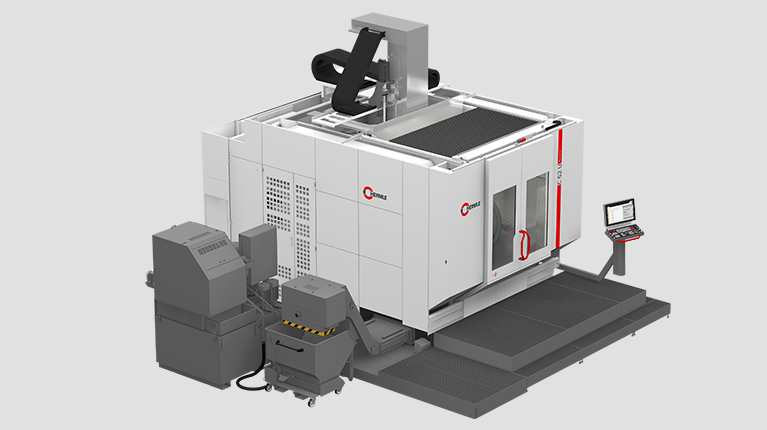

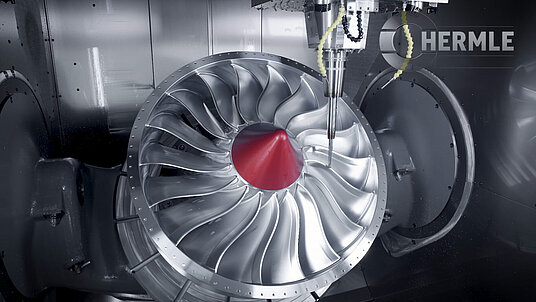

C 62 | Aircraft and aerospace industry | Fan module

HERMLE C 62 U MT dynamic in 5-axis mill-turn version, machining a fan module made of AlMg4.5Mn for the aircraft and aerospace industry

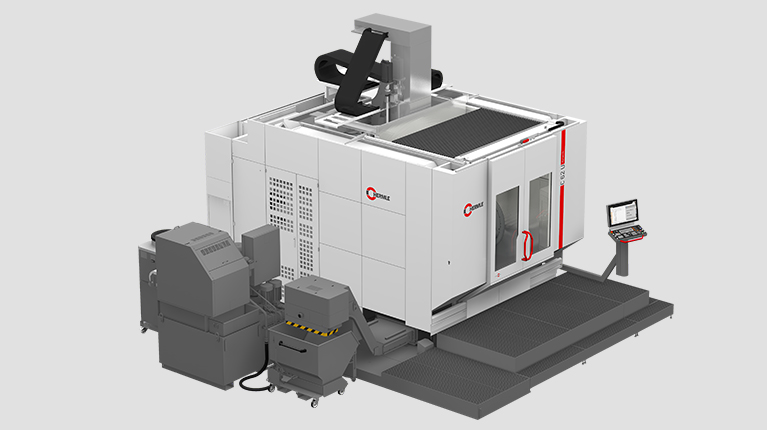

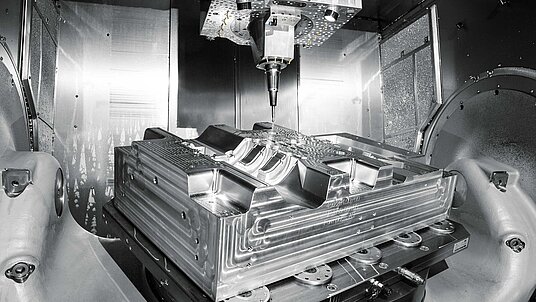

C 62 U MT | Machine construction | Spiral funnel

HERMLE C 62 U MT dynamic in 5-axis mill-turn version. Machining a spiral funnel in 42CrMo4 for machine construction

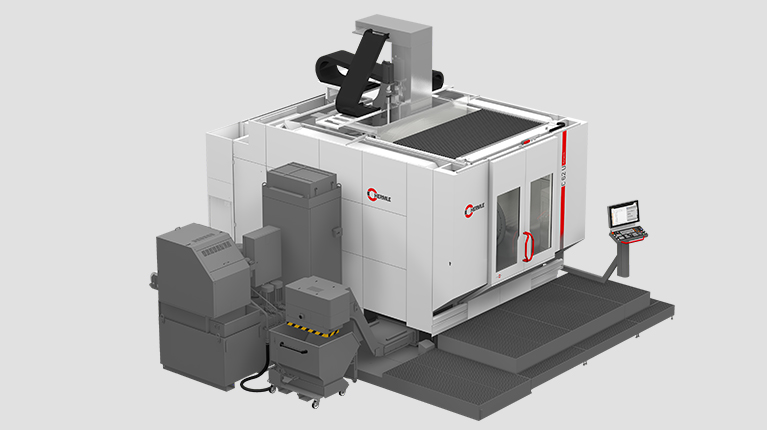

C 62 U MT | Vehicle technology | Railway wheel

HERMLE C 62 U MT dynamic in 5-axis mill-turn version. Machining a railway wheel in 1.1730 for vehicle technology. Use of an angle head – simultaneous turning.

User reports

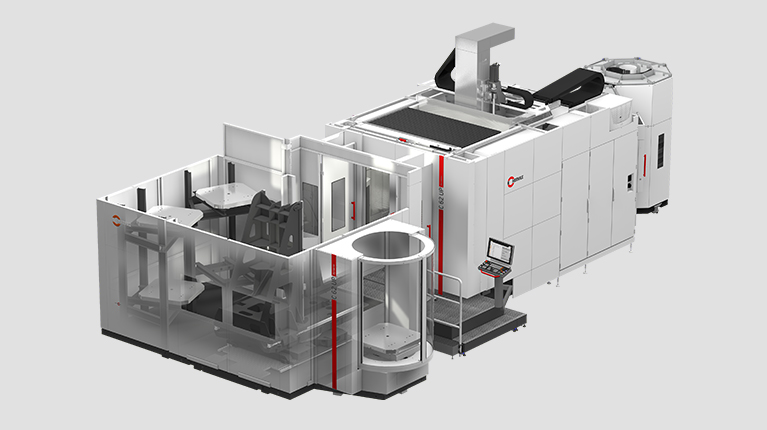

Cleverly decoupled for maximum efficiency

AMAG components Karlsruhe GmbH

Contract manufacturing

AMAG components Karlsruhe GmbH relies on automation: Pallet changer PW 3000 replenishes the 5-axis machining centre C 62 UP. Ever since the subcontractor separated machine setup from the actual machining process, there has been a significant and noticeable increase in spindle runtime and productivity.

5-AXIS MILLING EXPERTISE FOR ALL TOOL/MOLD COMPONENTS

Langer GmbH & Co. KG

Tool & mould making

Jörg Lehmann, team leader of NC production at Langer says: "In our independent department, thirteen highly qualified members of staff produce all the tool elements for mould making at ultra-modern CNC machining centres.

Getting the ratio right

Humbel Zahräder AG

Gear manufacturing

For the last five years, Humbel's reliance on the 5-axis concept and automation solution from Gosheim has enabled it to expand its capacities significantly and secure new orders.