Code from the CAD model

Producing individual parts almost unmanned – at the subcontractor FWM, software now generates the programming code. The HERMLE robot system RS 05-2 assumes the handling, while the specially developed application feeds the parts into the machine. A glimpse into the future of machining.

Dozens of angle pieces, all somewhat similar, yet no two are ever the same. Sometimes a leg is slightly longer, sometimes a hole is just a bit off-centre. “We primarily produce individual parts,” says Thomas Fuchs. He is the managing director of Fuchs Werkzeug- und Maschinenbau GmbH, or FWM for short. The angle pieces are used for body construction. “We produce over half of all the prototype devices for Mercedes-Benz worldwide,” he emphasises. These ‘turn-key’ solutions, i.e. ready-to-use systems, include, for example, welding equipment for the side panels of cars. Each package typically includes 30 to 50 components per vehicle type. “Thanks to automation, we now machine the parts entirely unmanned,” says the managing director. Carmakers use these devices to join together the individual body parts of the prototype using manual welding guns. In subsequent series production, a welding robot performs this task.

Thomas Fuchs founded the company in the German Saarland town of Lebach in 2006 and has since focused on growth. Today, about 100 dedicated employees and a network of subsidiaries combine their expertise to deliver complex solutions from under one roof. FWM focuses on modern processes, including CNC machining centres with 5-axis technology and automation. “None of our milling machines are more than ten years old,” Thomas Fuchs says proudly. “Over the past four years, we have modernised most of our production facilities and are increasingly using autonomous machines with pallet changers and individual part handling.” The company primarily processes different types of steel and aluminium, and the components are mainly used in the automotive and defence technology sectors.

-

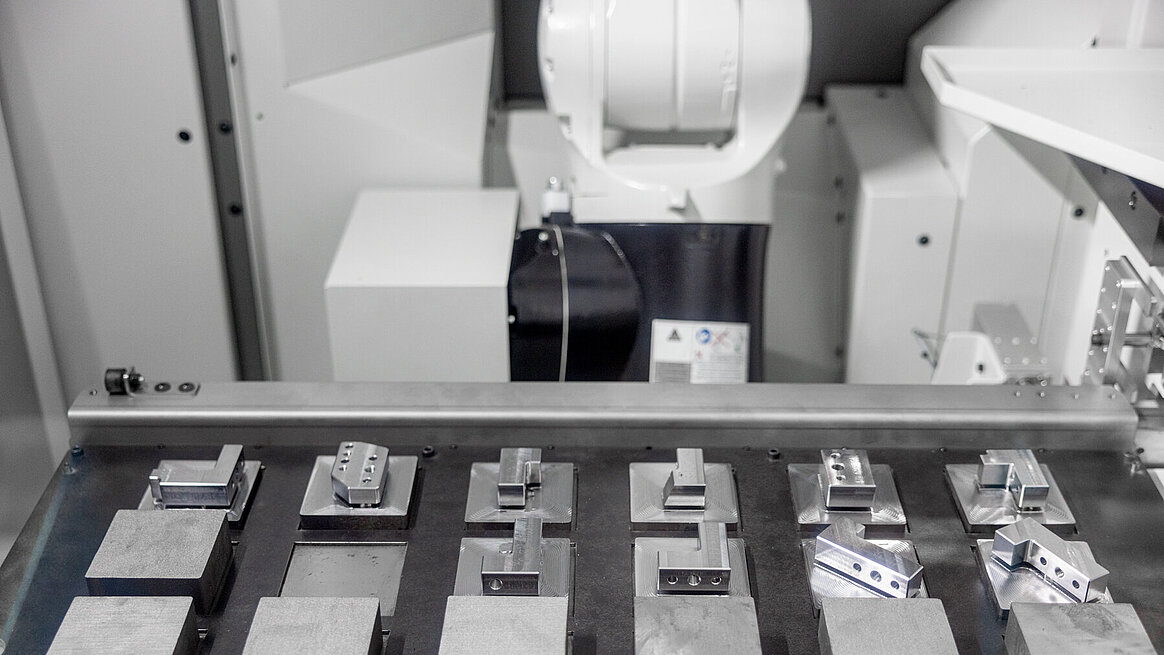

24/5 automated production – the 5-axis machining centre C 22 U with the adapted robot system RS 05-2. -

FWM primarily produces individual parts for the automotive sector on the C 22 U. -

FWM fertigt auf der C 22 U vor allem Einzelteile für den Automotive-Bereich. -

FWM primarily produces individual parts for the automotive sector on the C 22 U. -

22 hours of operation, around two hours of setup time – the C 22 U runs mostly unmanned. -

Thanks to fully automated processes, FWM produces around the clock, five days a week – despite two-shift operation. -

Spot the difference – the components for prototyping are similar but never identical.

When the code writes the code

Is it even possible to prepare and produce individual parts using automated techniques? “Definitely,” says Thomas Fuchs. Latest example: The 5-axis machining centre C 22 U with the adapted robot system RS 05-2 from HERMLE. Since 2024, FWM has been using the system combination to machine components measuring 80 to 120 millimetres in edge length unmanned. 55 tools in the machine and 50 more in the additional magazine ZM50 ensure sufficient flexibility. “Since we produce individual parts, we did not want to compromise on the machine. That did not make any sense to us. Further, the machining centres have to be fully equipped to also fulfil new orders,” says Thomas Fuchs with a grin. “True to the motto: Better to have than to need.”

However, the stand-out feature is FAMS (Fuchs Automated Milling Software), specially developed by FWM for this purpose. It writes the code, thus effectively replacing both the programmer and the person who runs in the component. “We only have to import the CAD data, FAMS handles the rest,” explains Johannes Voit, co-managing director at FWM.

The team worked on it for several years, and the program can now prepare most components for machining fully automatically. “Our typical batch size is 1,” explains Thomas Fuchs. “We therefore sought a solution that would manage parts handling and significantly reduce the programming effort.” HERMLE supported us in the software development and stood by us as a partner with its expertise.” The system’s capabilities were thus fully utilised and, despite two-shift operation, the company is now able to produce 24 hours a day, five days a week.

Series production of individual parts

Besides the C 22 U, FWM also operates four HERMLE C 400 U machines. “We rely on redundant machines to ensure our software works identically across all systems,” says Johannes Voit. The first machining centre joined the machine park in 2018, with others being added nearly every year since. “I like buying machines,” admits Thomas Fuchs mischievously. “But seriously: These machining centres are simply first-class, and our CNC millers enjoy working with them.” Johannes Voit adds: “Our experience has been positive overall, not just in terms of precision, but especially with regard to the quality of the service. A HERMLE technician usually arrives within hours of reporting an error and resolves the issue.” To this end, the uniform design of all the machining centres from Gosheim and the technicians’ deep familiarity with them also play a key role.

Two of the C 400 U machines are supplied automatically with workpiece carriers by the handling system HS flex. “Adopting pallet handling was a milestone for us,” recalls Johannes Voit. “It allowed us to introduce our workers to the technology and to demonstrate its potential.” Thomas Fuchs adds: “Our philosophy is to use our machines to make production attractive to qualified employees. We have a young team, and the colleagues are very eager to learn.” This is why FWM also favours hybrid workstations: The CNC millers not only operate the machines but also program them, steadily expanding their CAM skills. “That makes our jobs truly interesting,” the managing directors affirm.

Orders under control, machines in view

HACS – HERMLE “Automation-Control-System” and HIMS – HERMLE “Information-Monitoring-Software” control and monitor the robot and handling systems. This enables advance planning of operating times and tool usage, while simplifying the assignment of NC programs and zero points. Changes to the sequence plan are possible at any time. Beyond a compact live view, the monitoring tool provides detailed status histories and message logs.

Was the investment in the new robot system worthwhile? “A definite yes! I have done the maths: Without this system, we would need nine more people during peak project phases – and an additional machine on top of that,” explains Thomas Fuchs. His partner adds: “When we produce unmanned, we lower the costs per part. Skilled labour shortage and staff availability are two more strong arguments for automation. This allows us to maintain our capacities and to guarantee on-time delivery for all our customers combined with high quality.”