Trading in industrial yarns, high-end bicycles and precision parts – Chr. Held GmbH & Co. KG has a diverse portfolio. Since 2023, the subcontractor has been prioritising automation: Together with the RS 05-2 robot system, the C 250 U from HERMLE turns night into day. The result: High efficiency through smart automation.

Managing director Maximilian Held is convinced that automation is not just a growth driver but a necessity for the company to stay competitive in the future. Since 2023, the company founder’s great-grandson has relied on the RS 05-2 robot system from HERMLE at HELD Präzisionstechnik, which handles parts on the C 250 U five-axis machining centre. "At least two of our qualified employees have stayed with us because three-shift operation wouldn’t align with their personal lives. Our flexible one-shift solution provides ample flexibility for our workforce. And thanks to automation, we can manufacture unmanned at night and at weekends," he emphasises.

A traditional company embracing the future

Chr. Held GmbH & Co. KG traces its roots back to the textile industry. Founded in 1919 in Schelklingen, near Ulm, as a doubling and dyeing mill, the company evolved into a successful subcontractor in the metalworking industry. "By the late 1970s, we began manufacturing a variety of turned and milled parts for external companies in the region," explains Maximilian Held.

Today, the company is a trusted partner across various industries, supplying sectors such as mechanical and plant engineering, special vehicle construction and the agricultural and food industries. Many workpieces are delivered to the neighbouring Alb-Danube region. HELD also continues to trade in industrial yarns and operates the Bike Station, a store for high-quality bicycles, as its third mainstay in Blaubeuren.

A pivotal milestone in the company’s history was the demolition of the old building in 2019 and the relocation to a modern, new facility. In addition to improved manufacturing conditions, HELD also established the foundation for automated production in the new facility. "We’d reached the limits of our capacity in the old premises, and expansion was not feasible for several reasons. Due to the low ceiling height, we were very limited in our choice of machines. The material flow in the old production facility was chaotic, and modern production with single-glazed industrial windows was simply not possible. Until 2019, we were essentially working in an industrial monument," explains the managing director.

Stepping into automation

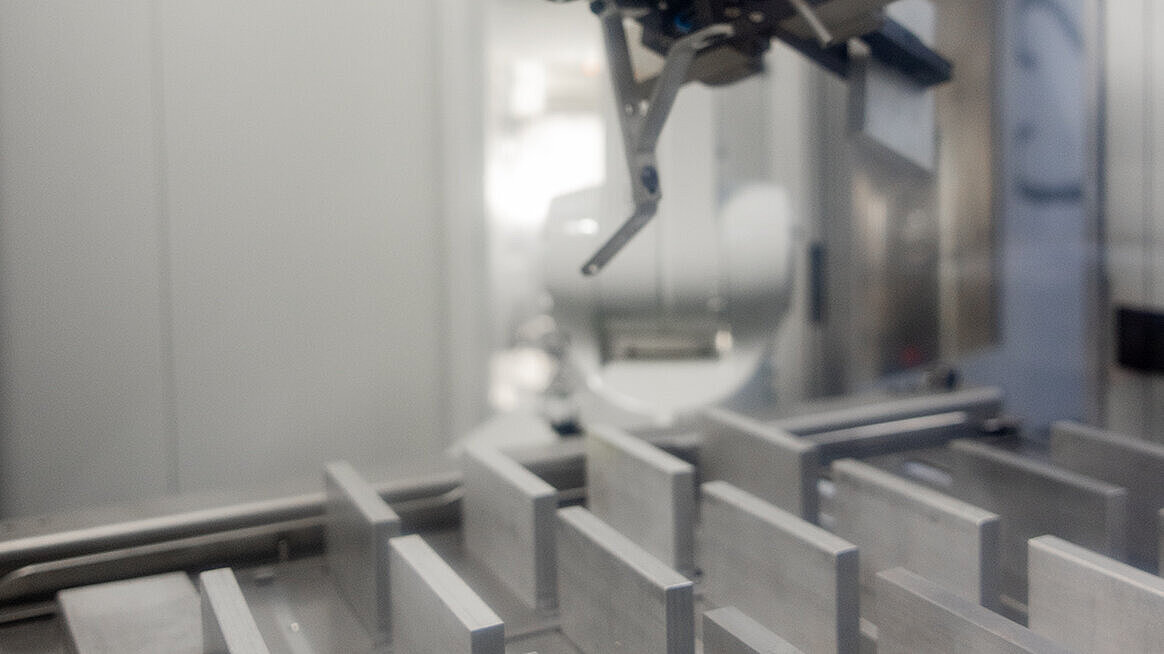

To address rising competitive pressure and the shortage of skilled labour, HELD Präzisionstechnik invested in an automated milling centre. The decision was made to go with a HERMLE C 250 U equipped with the RS 05-2 robot system. A combination perfectly suited to the company’s needs. "We had already gained experience with our C 32 U and were impressed with the machine from day one," says Maximilian Held.

The C 250 U fits seamlessly into the range of parts and offers a very large working area in relation to its installation area. As part of HERMLE’s Performance Line, it delivers robust and precise five-axis machining with exceptional dynamics and flexibility. "It was clear to me: We can no longer do without automation," emphasises managing director Held. "The machine must operate continuously, even if nobody is in the workshop. This is the only way we can significantly increase our efficiency and stay competitive."

This decision was both strategically important and correct: During the day, the company manufactures individual parts and small series of five to ten workpieces on the system. For the night and the weekend, the workers convert the machine for unmanned operation. "The longest continuous operation to date lasted 52 hours, during which the machining centre machined 200 parts," reports Maximilian Held. "The limiting factor was the drawer space – we just couldn’t prepare more blanks."

Fully integrated

The compact and flexible RS 05-2 automation solution is ideal for small and medium-sized workpieces. Thanks to its modular design, it can be seamlessly integrated into existing production processes. "It’s fantastic how effortlessly we can switch between manual and automated production," says a pleased Edwin Lemmle. Having been with the company for over 40 years, he is the key person responsible for the C 250 U. Maximilian Held adds: "The RS 05-2 can handle various workpieces, making small series production cost effective." The decision to invest in an automated milling centre quickly proved beneficial: "We were able to increase our spindle runtimes by more than 50 per cent."

Roland Füller, production foreman, also praises the system: "The Hermle C 250 U is the ideal solution for us. It’s not only highly precise but also reliable and low maintenance. Thanks to the five-axis technology, we can consolidate many work steps, making machining more efficient." Instead of multiple clamping operations, the machine now machines the workpiece in a single clamping process. This saves time, enhances precision and improves the dimensional accuracy of the components.

"I’ve worked with many different machines in my career, but the C 250 U is truly something else," emphasises Edwin Lemmle. "Switching from three-axis to five-axis machining with automation was a challenge at first, but with the training in Gosheim and the intuitive controls, I quickly mastered it."