Youthful experimentation was yesterday

What started as an improvisation with a lightweight robot now runs with HERMLE automation technology: PAWA-Tech demonstrates why switching to professional equipment makes the difference. The 5-axis machining centre C 22 U with the adapted robot system RS 05-2 has propelled the subcontractor to new levels of productivity.

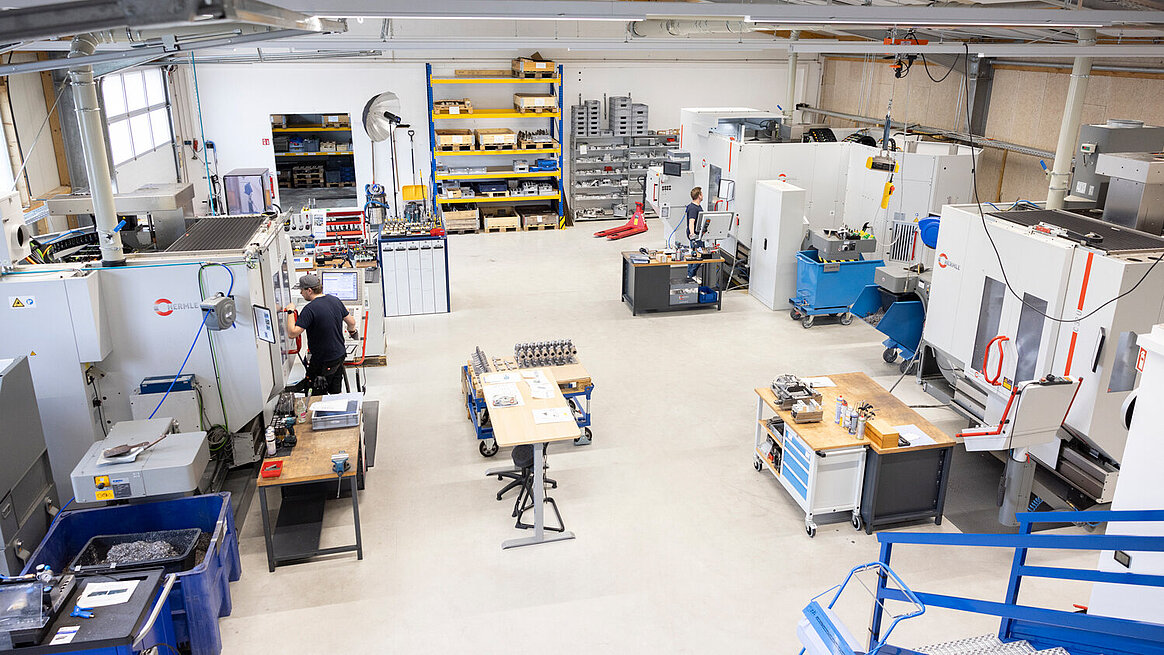

In 2016, Paul Walczok Jr. founded PAWA-Tech GmbH in Essenbach, not far from the Bavarian town of Landshut. “Basically a garage startup,” he says. One room, one C 250 U, one tiny office. Business thrived; and by 2019, a second HERMLE machine was needed. The company relocated. With the help of friends, a forklift truck and a cordless screwdriver, the new workshop was prepped, the floor poured and the machines installed – including the C 250 U. “Two weeks later, the crane returned to install the new C 32 U. It was up and running in just a few days,” recalls the managing director.

PAWA-Tech has a broad foundation, serving the automotive, hydraulics, aerospace and medical technology industries. “However, most of our parts end up in motor sports,” reveals Paul Walczok. The company machines aluminium, steel, stainless steel and plastics.

Implemented calmly and with a plan in mind

Automation was an issue from the outset. “I built the first automation system for the C 250 U myself,” says Paul Walczok proudly. “A lightweight robot, a few control components, with the charm of youthful experimentation.” But somehow, it worked. “It taught me what truly matters: Chip removal, coolant supply and, of course, above all else, process reliability.” In 2023, he took a major step: Acquiring a C 22 U equipped with an adapted HERMLE robot system RS 05-2. This time from professionals and from a single source. “We took our time planning, carefully considering the machine’s equipment and the robot system’s tasks,” the entrepreneur explains. To do so, he rebuilt the workshop, expanded the production space and added a new office wing.

For almost a year now, the automation system has been operating unmanned overnight. During the day, the qualified employees run the three machining centres in two shifts. At night, a robot colleague operates the C 22 U. PAWA-Tech now produces batches of ten or more components fully automatically. “This has proven especially effective for workpieces with long runtimes. It keeps the machine busy all night,” says the company founder.

-

The high-performance machining centre C 22 U offers enormous flexibility. -

PAWA-Tech relies on HERMLE: First the C 250 U, then the C 32 U, and since last year, an automated C 22 U has also been machining components. -

The uniform operating concept enables the qualified PAWA-Tech employees to easily switch between machining centres. -

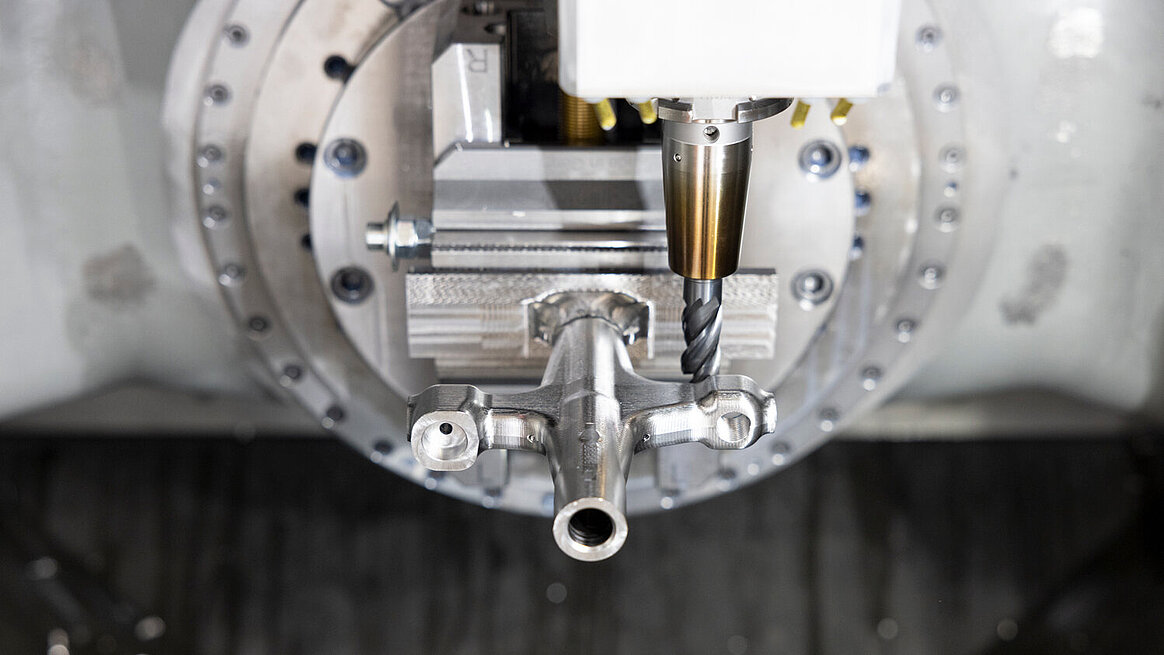

Many of the machined components are used in motor sports. -

Whether machining just one, a dozen or a thousand workpieces – PAWA-Tech meets all the demands through automated production. -

Whether machining just one, a dozen or a thousand workpieces – PAWA-Tech meets all the demands through automated production.

Compact solution, great effect

A 6-axis industrial robot handles blanks weighing up to ten kilograms, changes different grippers fully automatically and can thus flexibly move various components. PAWA-Tech uses a five-drawer storage that can hold 50 to 90 workpieces on each level. The universal dies can be quickly adapted to changing components. The robot system RS 05-2 has a very compact design, only requiring an installation area of around two square metres, and allows operators unrestricted access to the working area and rack storage. It is fully integrated into the HERMLE environment and can be operated via a touch pad. The HERMLE “Automation-Control-System” (HACS) shows, for example, an overview of the orders, the sequence plan as well as tool data and prioritisation. Thanks to the long-stroke clamping device and the drawer system, various component sizes can be clamped without the need for conversion.

None of the 13 employees feared automation. “I clearly communicated what I want to achieve. My staff should be able to focus on their specialist skills, for example programming machines and optimising processes, while the robot takes care of the simple insertion work,” emphasises Paul Walczok. “All the colleagues can operate the system and perform standard tasks. With a bit of thought, it does not take long to master the controls,” as he knows from experience. Two of the qualified employees have since specialised in the automated system, gaining extensive expertise.

More milling time, more possibilities

The spindle runtime has doubled since the robot’s introduction. While the conventional machines operate in two shifts, the C 22 U with the RS 05-2 also mills overnight. “Today, 24/7 is only possible with automation,” Paul Walczok asserts. “If a customer orders ten more parts over the weekend on Friday evening, we can deliver them thanks to the robot system.” This flexibility is especially valuable in times when the order books are not quite so full.

Why does Paul Walczok place such consistent trust in HERMLE? He does not think twice before answering. “Because it works. The machines are extremely reliable. And should we need to report a fault, a replacement arrives the very next day. “This is crucial for our daily operations and delivery reliability.” With deep industry insight, he understands how much time can be lost when no one takes responsibility. “That is the great thing about HERMLE. Machine, robot, service – there is one phone number for everything and a single point of contact who resolves any issues promptly.”

The second reason is the high precision of the machining centres. “In motor sports, we work with tight tolerances and mill complete cylinder heads on the C 32 U – including channels and fits,” explains the managing director. Depending on the component, this process can take up to a full day. “Precision on five axes – that is our business.”

PAWA-Tech exemplifies modern production: Precise, flexible and well organised. The blend of machining centre, robot system and the reliable HERMLE service makes all the difference. Paul Walczok and his team can count on this. For motor sports and other demanding customers, this means more than just words. It is about components that fit perfectly, processes that run smoothly and machines that never break down overnight.