The elite class of automation solutions

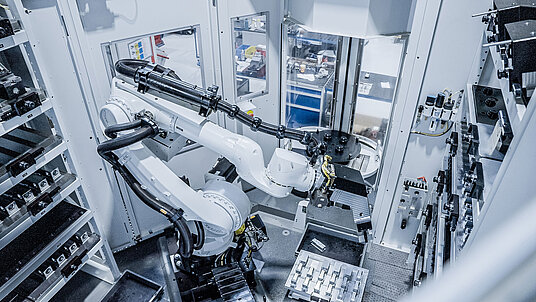

- Individually configurable and highly flexible, whether for pallet handling, changing workpieces from dies and/or directly.

- Gripper change from single to double gripper for even more flexibility.

- Wide range of magazine configurations to suit individual customer requirements.

- The robot systems can be adapted to all HERMLE machining centres and they are also available in different versions.

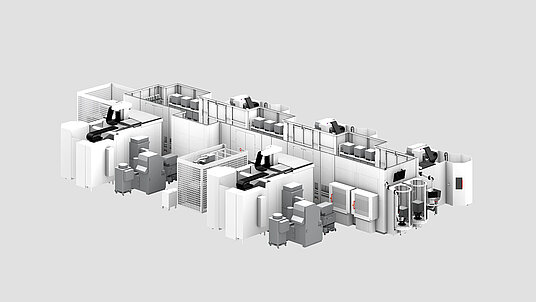

- From the RS 05-2 robot system for small pallets and components to the RS 3 system with a transport weight of up to 420 kg, also including highly productive systems with linear linking.

Overview of robot systems

RS 05-2 robot system

- Designed for individual requirements and extremely flexible.

- Available for the HERMLE machining centres C 12, C 22, C 32 and C 250

- Transport weight: up to 10 kg

RS 1 robot system

- One system. Endless possibilities

- Available for the HERMLE machining centres C 12, C 22, C 32, C 42, C 250 and C 400

- Transport weight: up to 60 kg

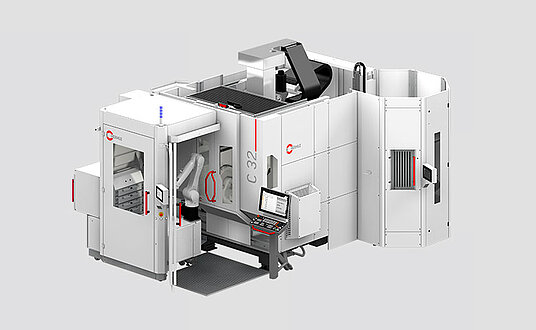

RS 2 GEN2 robot system

- Compact, highly modular robot system

- Available for the HERMLE machining centres C 22, C 32, C 42, C 52, C 250, C 400 and C 650

-

Six-axis robot with a load capacity of 210 kg

RS 3 robot system

- Versatile and individual

- Available for the HERMLE machining centres C 42, C 52, C 400 and C 650

- Transport weight: up to 420 kg

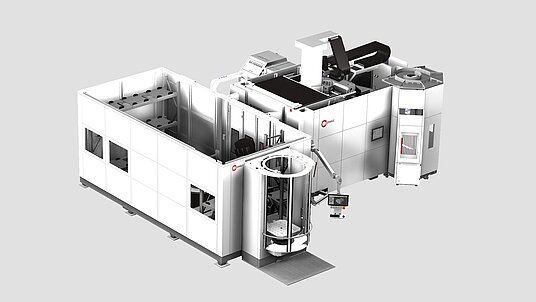

RS L robot system

- Variable for maximum productivity

- Available for the HERMLE machining centres C 22, C 32, C 42, C 52, C 250, C 400 and C 650

- Transport weight: up to 420 kg

User reports

Discover what our customers say about us.

Flexibility thanks to robot automation

SWACRIT systems GmbH

Medical technology

SWACRIT systems GmbH specialises in the production of top-quality composite parts, mechatronic assemblies and high-precision mechanical components. To enhance productivity and efficiency, the high-tech company based in Tyrol, Austria, has invested in HERMLE's RS 1 robot automation solution, which enables the flexible and continuous manufacture of individual parts and components on pallets.

Digitalisation: the foundation for automation

Microart GmbH & Co. KG

Contract manufacturing

High variance and different batch sizes can cause many a contract manufacturer to panic – but not microart. The manufacturer of complex precision parts creates digital structures, which it combines with automated 5-axis machining centres from Hermle. The result: efficient milling with flexible capacity.

Open to new ideas

Hohner Maschinenbau GmbH

Contract manufacturing

"We have known Hermle for decades and have been working together for a very long time. We had confidence in them right from the start. The service and technology have once again impressed us," praises the Managing Director.

Available on demand

CNC-Welcker

Contract manufacturing

The subcontractor CNC-Welcker specialises in medical technology, aerospace, the optical industry, gas and microscanning technology, as well as mechanical and plant engineering. Its promise: To deliver perfect quality, even when significant time elapses between orders. Thanks to the RS 2 robot system from HERMLE and the two adapted C 32 U 5-axis machining centres, the company now achieves its goal with ease.

Youthful experimentation was yesterday

PAWA-Tech

Contract manufacturing

What started as an improvisation with a lightweight robot now runs with HERMLE automation technology: PAWA-Tech demonstrates why switching to professional equipment makes the difference. The 5-axis machining centre C 22 U with the adapted robot system RS 05-2 has propelled the subcontractor to new levels of productivity.