Generation 2 from HERMLE – a new era of machining centres and automation solutions – live at EMO 2025

With three fully automated systems and a mill-turn machining centre, HERMLE relies on proven tradition – coupled with the latest innovation. All models will be exhibited in GEN2 design, each with interesting machining examples. At the special "Technology Development" stand, hardware and software components, digitalisation projects and milling/machining cycles, as well as components from our training expertise, will be showcased. Everything can be seen in Hall 12 at Stand C 30 of Maschinenfabrik Berthold HERMLE AG from Gosheim.

A brief introduction to the exhibits

The 5-axis machining centre C 12 GEN2 from the high-performance series with the robot system RS 05-2.

The robot system RS 05-2 handles workpieces weighing up to 10 kg while at the same time storing a large number of individual parts in a wide variety of storage modules. An aluminium medal is being machined which can also be used as a PIN magnet.

Video showing how the medal was machined on YouTube.

The 5-axis machining centre C 32 GEN2 from the high-performance series with the robot system RS 2 GEN2. HERMLE AG is now taking automation to a new level with the GEN2 version of the robot system RS 2. Almost all components of the previous RS 2 system have been enhanced and optimised to meet customer requirements. A detailed press release on the robot system RS 2 GEN2: PI13052025.

-

5-axis machining centre C 32 GEN2 with robot system RS 2 GEN2, additional magazine ZM 419, HEIDENHAIN TNC7 automation demo - intelligent storage strategy in a wide variety of rack modules -

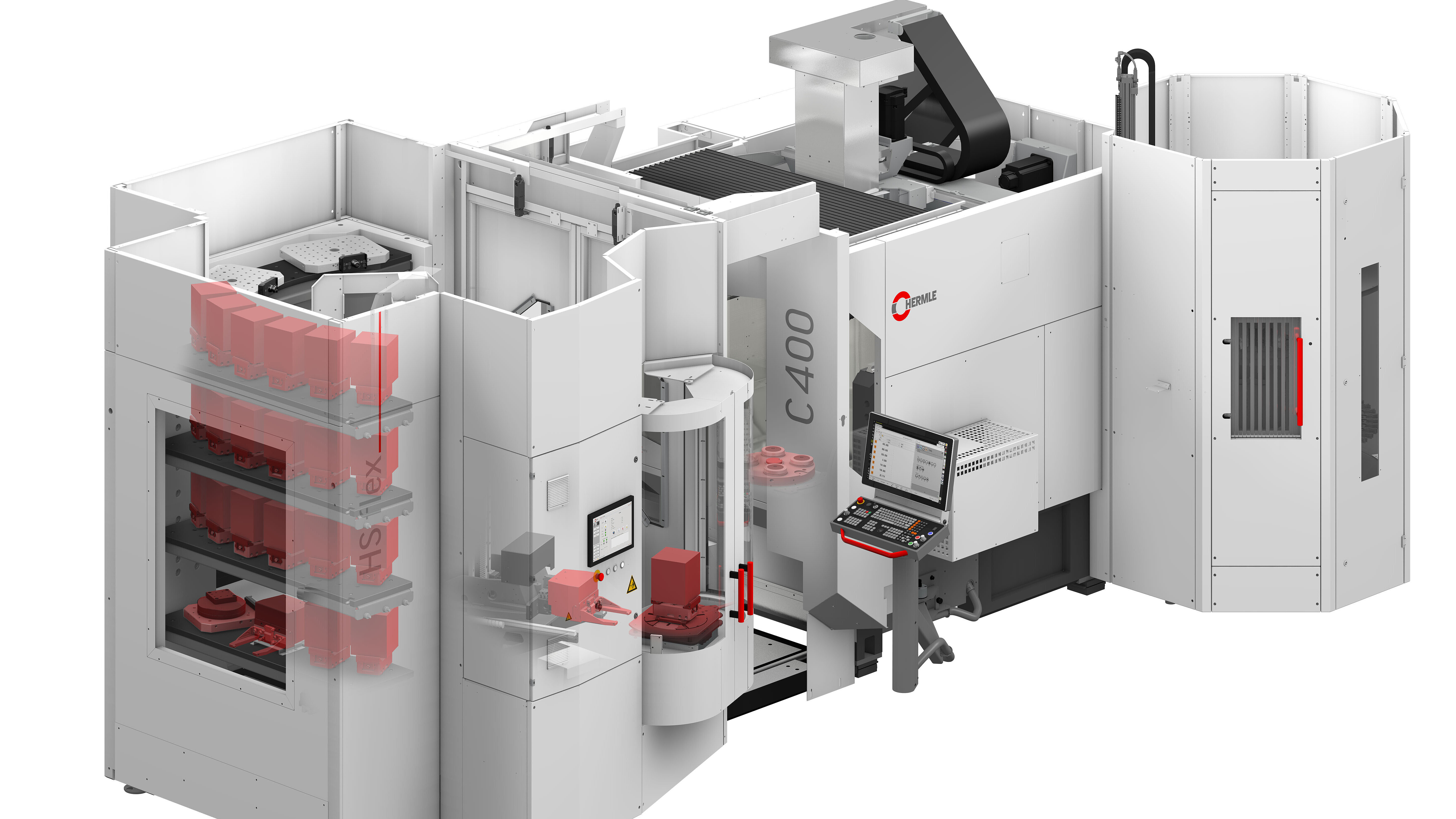

5-axis machining centre C 400 GEN2 with handling system HS flex hybrid, storage modules, additional magazine ZM 88k, HEIDENHAIN TNC7

Automation demo vise pallets -

Machining of an aluminium magnetic PIN medal with a 5-axis machining centre C 12 GEN2 with robot system RS 05-2, additional magazine ZM 35, HEIDENHAIN TNC7 -

HERMLE 5-axis machining centre C 12 GEN2 with robot system RS 05-2 -

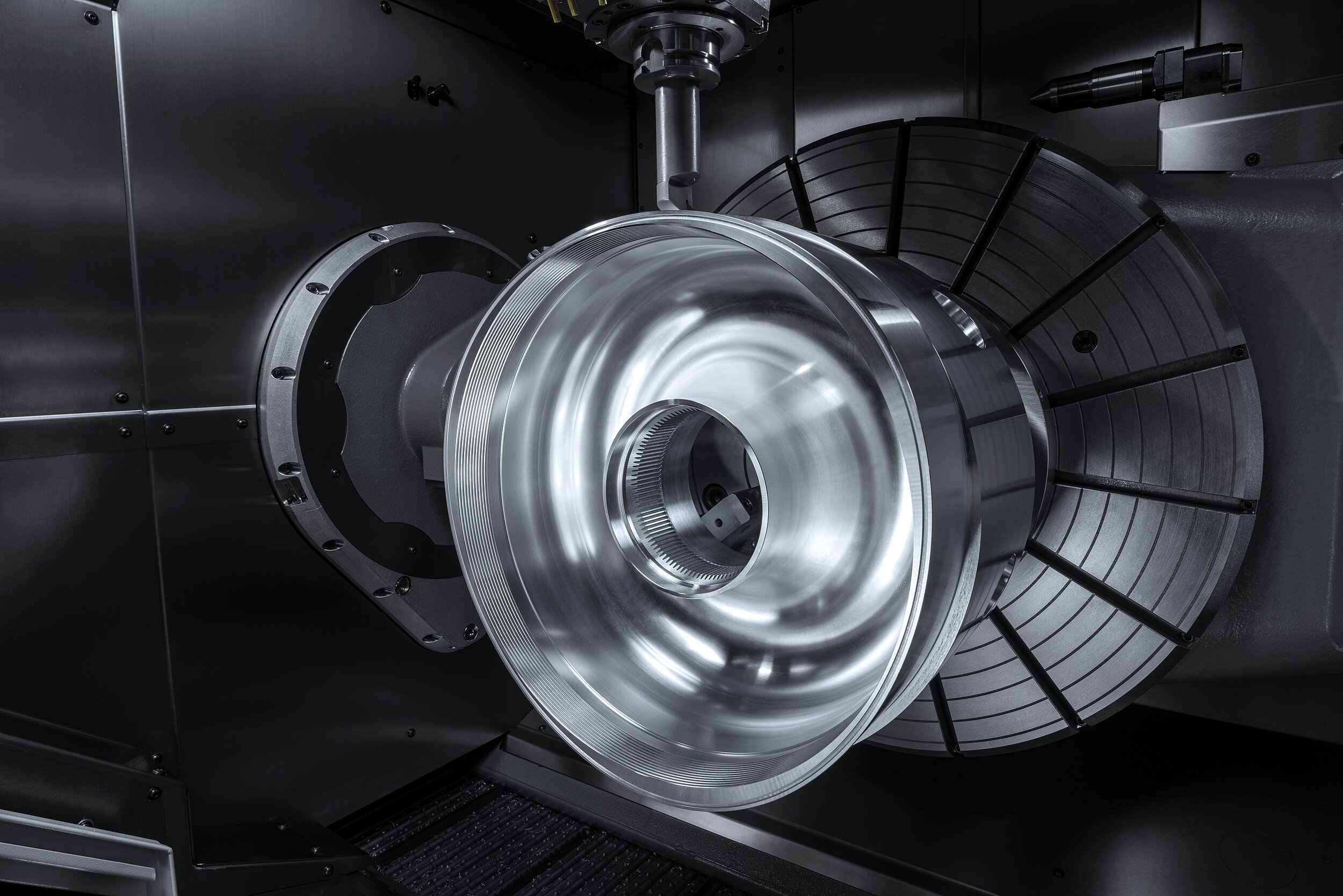

5-axis machining centre C 42 MT GEN2 (Mill-Turn)

additional magazine ZM 216, SIEMENS SINUMERIK ONE

Machining of a workpiece using a wide variety of turning cycles

The 5-axis machining centre C 400 GEN2 from the performance series with the handling system HS flex hybrid. With the handling system HS flex hybrid, HERMLE is taking the previous handling system HS flex to the next level of performance for the economic production of components weighing up to 450 kg. The system transports both pallets and vises from the setup station to the storage modules or the working area. The following components have all been specially configured for the HS flex hybrid – storage modules, setup station, gripper and adapter pallet. Further, the HS flex hybrid can be adapted to six different machine models and configured with either one or two storage modules. A detailed press release on the handling system HS flex hybrid: PI14052025.

The 5-axis machining centre C 42 MT GEN2 from the high-performance mill-turn series. Equipped for the first time with the SIEMENS SINUMERIK ONE control, the C 42 MT is used to machine a technology component into which a wide variety of turning technologies have been integrated.

These "turning cycles" in detail: Bright turning, eccentric turning, taper turning, out-of-round turning of a polygon contour, contour broaching of any 2D contour, simultaneous turning of the inner contour, thread turning, recess turning, power skiving, QR code drilling.

Video showing the turning technology component on YouTube.

Visit HERMLE at the EMO 2025

HERMLE AG | Hall 12 | Stand C 30.

Contact details for journalists/editors:

Maschinenfabrik Berthold HERMLE AG / Marketing Department / Email: marketing@hermle.de / Phone +49 (0)7426 95-0

78559Gosheim