C 42 U | HK Präzisionstechnik | Precision engineering

Technology company HK Präzisionstechnik GmbH is increasingly focused on the use of five-axis high-performance machining centres from Hermle in its component manufacture for workpiece clamping systems and for tool and mould making.

Based in Oberndorf in the Black Forest region of Swabia in south-western Germany, the traditional company name of Heckler & Koch is a byword for quality. During the 1980s the business diversified into various civilian sectors, such as machine tool manufacture, the development and manufacture of diamond wire saws, tempering units, and workpiece clamping devices. The company's expertise and know-how is of course firmly founded on its many years' experience in the industrial manufacture of precision parts. Since 1993, that expertise has been deployed solely for the benefit of the civilian sector. It was then that engineer Xaver Mayer and a number of colleagues from H&K's Tool Making department took the major step of going it alone, and established HK Präzisionstechnik GmbH. Today, managing partner Xaver Mayer and the other two shareholders, R&D manager Horst Scheidt and Jörg Grammel, head a team of 45 specialists focused primarily on the development and manufacture of diamond wire saws, tempering units and workpiece clamping systems. Most of the sales revenues are generated by workpiece clamping systems and the production of jigs and fixtures. As Xaver Mayer asserts, the company's structuring across three-divisions, focused on three different fields of competency, has proved highly successful over the years in enabling HK Präzisionstechnik GmbH to withstand all economic ups and downs.

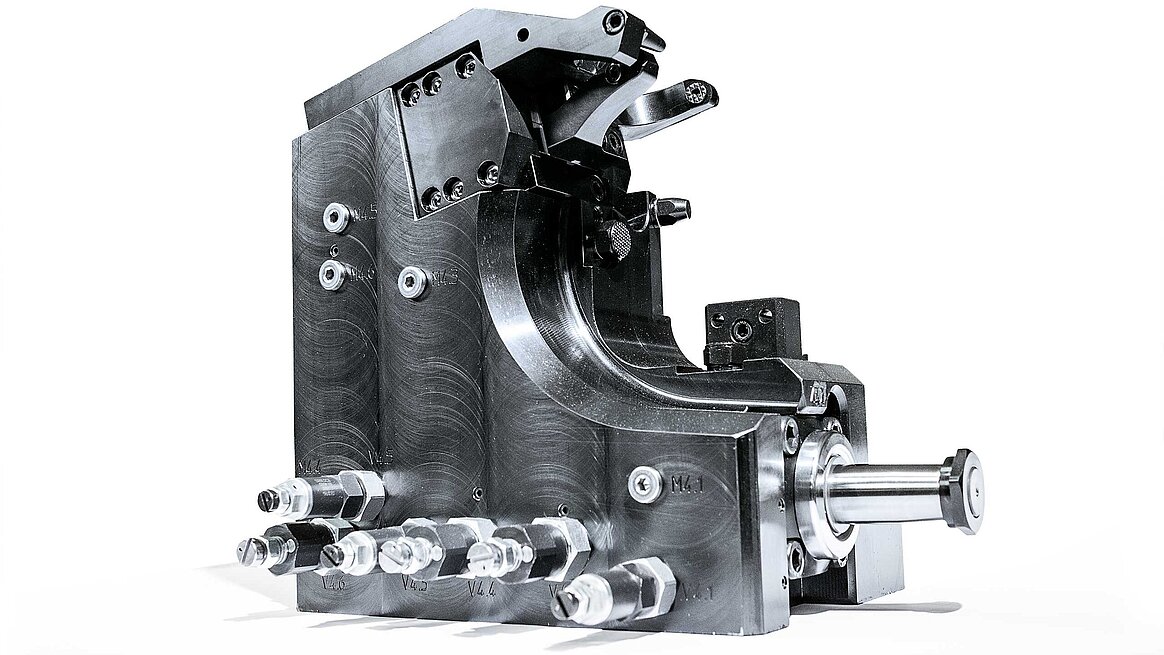

Speciality: High-end clamping solutions for mass production

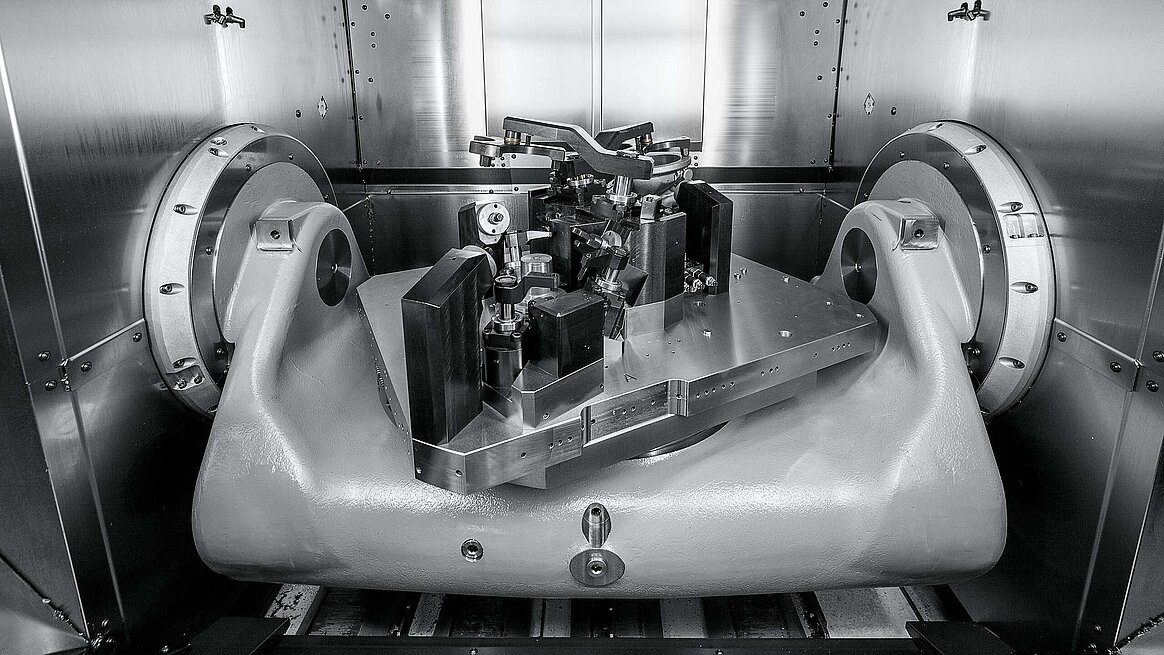

Having taking on highly qualified staff and acquired machinery and equipment from H&K's tool making operation, the workpiece clamping and jigs and fixtures business was ideally placed to enjoy prosperous growth, and is today a go-to address for high-end workpiece clamps and complete clamping system solutions used in the machining of automotive components. The fact that 10 of the 45 staff work in the Design department is in itself a clear indication that HK Präzisionstechnik is very much focused on custom clamping solutions rather than just standard clamp fixtures. The design and production operations are based on mapping of the manufacturing process and the use of standardised modular kit-type components. Nevertheless, there are always some components which have to be designed and made in line with specific product and process requirements. As the business grew, and especially when a major contract was acquired to develop and produce a series of workpiece clamping systems, it was found that the existing machine tools for cubic machining were simply no longer capable of meeting the increased demands, and were hampering cost-effectiveness. Consequently, the decision was taken to switch as fast as possible to automated five-axis complete machining. A period of intensive evaluation followed. This led Xaver Mayer, Horst Scheidt and production manager Wolfgang Cmelik to contact Frank Keller, project sales executive with HLS Hermle-Leibinger Systemtechnik GmbH. Frank Keller had already worked with HK Präzisionstechnik GmbH to implement some high-end, turnkey complete clamping and machining systems for the production of a wide variety of precision parts, so he was well aware of the high demands involved, but also knew what the highly skilled team was capable of, and that familiarity proved ultimately of great benefit to both parties.

Launch of high-level, precision-controlled five-axis machining: Hermle C 42 U

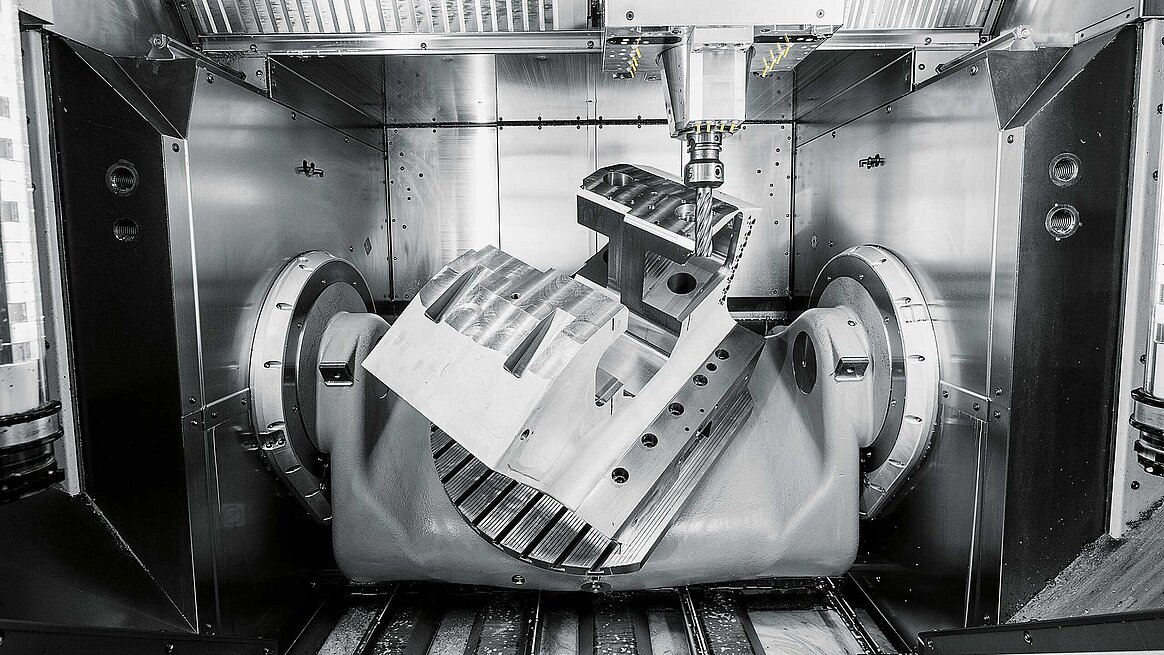

Following a thorough analysis of its customer's needs, and based on the current and expected range of components to be machined, HLS recommended that HK should switch to five-axis complete/simultaneous machining with a type C 42 U high-performance five-axis CNC machining centre from Hermle. Horst Scheidt comments on the switch to five-axis machining: "We were already running high-performance precision machinery, but we often had to make complex arrangements for special machining applications or to obtain a truly precision finish. The need to outsource meant that time was frequently lost, quality was sometimes not entirely satisfactory, and we had to reconfigure clamping systems, switch machines, or make other adjustments. That is now no longer the case. We complete all the necessary parts in one or two clamp fixings, to the highest quality standards, all in a single operation." With a working range of X = 800, Y = 800 and Z = 550 mm and a table load capacity of 850 kg (based on the installed 800 x 630 mm NC swivelling rotary table), the C 42 U size machining centre is ideally suited to the demanding machining operations carried out by HK Präzisionstechnik GmbH. A highly advantageous design feature is the concept of three axes in the tool and two in the workpiece, in which short finishing cutters or deep-hole drills or long-projecting milling tools can be optimally positioned for the complete machining of large-format clamping system base bodies weighing more than 700 kg for example. Experienced production manager Wolfgang Cmelik reports: "After just a short learning and running-in period, we were able to substantially reduce production times for some workpieces. We don't have to switch to precision drills, because the C 42 U produces even 700 kg items with such precision and angular accuracy that the workpieces meet the very highest quality demands. We only need to reclamp in exceptional cases; otherwise the machining is now all in a single process. The Hermle C 42 U can do much more than what is stated in the brochure, and as a result we have been able to eliminate at a stroke many of the problems that previously demanded a more interdisciplinary approach to component production."