C 42 U | RS 2 | Rohde & Schwarz GmbH & Co. KG | Electrical Engineering

The Teisnach plant, a centre providing services for mechanical and electronic manufacturing in the plant network of Rohde & Schwarz GmbH & Co. KG, uses automated CNC high performance machining centres from Hermle.

"Factory of the year – outstanding small series manufacturer 2010", followed by "Best Factory 2013" and this year the Bavarian Quality Award – There's probably more to learn from any company that has garnered awards of this calibre than you would expect from a traditional supplier of mechanical parts and subassemblies. Especially since products and solutions developed by Rohde & Schwarz GmbH & Co. KG are almost always related to electronic measuring and communication technology, and mechanical manufacturing is not really their core business, or is it? In practical terms, the Teisnach plant, founded in 1969, is responsible for premanufacturing of numerous products for Rohde & Schwarz GmbH & Co. KG, a globally operating electronics group with headquarters in Munich, Germany. About 1400 specialists in Teisnach manufacture electromechanical subassemblies and special parts, wireless communication systems, transmitter systems for radio and television as well as printed circuit boards, housing parts, electricity charging stations and waveguides in a production area of 62,000 m2. The service portfolio includes all relevant areas of mechanical and electronics manufacturing. And these services are available not only to Rohde & Schwarz, but to other external customers as well. The philosophy of maximum internal manufacturing is backed up by extremely high requirements for quality and flexibility, and to guarantee that internal manufacturing is economical and efficient, the company uses adequate (meaning the latest available) equipment that allows for flexible use. Since electronic measuring and communication systems consist of numerous individual parts (as they always have) which are increasingly functionally integrated and therefore challenging mechanical components, machining operations play a leading role. Because of this there is a department for milling and turning technology in the Teisnach plant, further divided into "Vertical" and "Horizontal" areas.

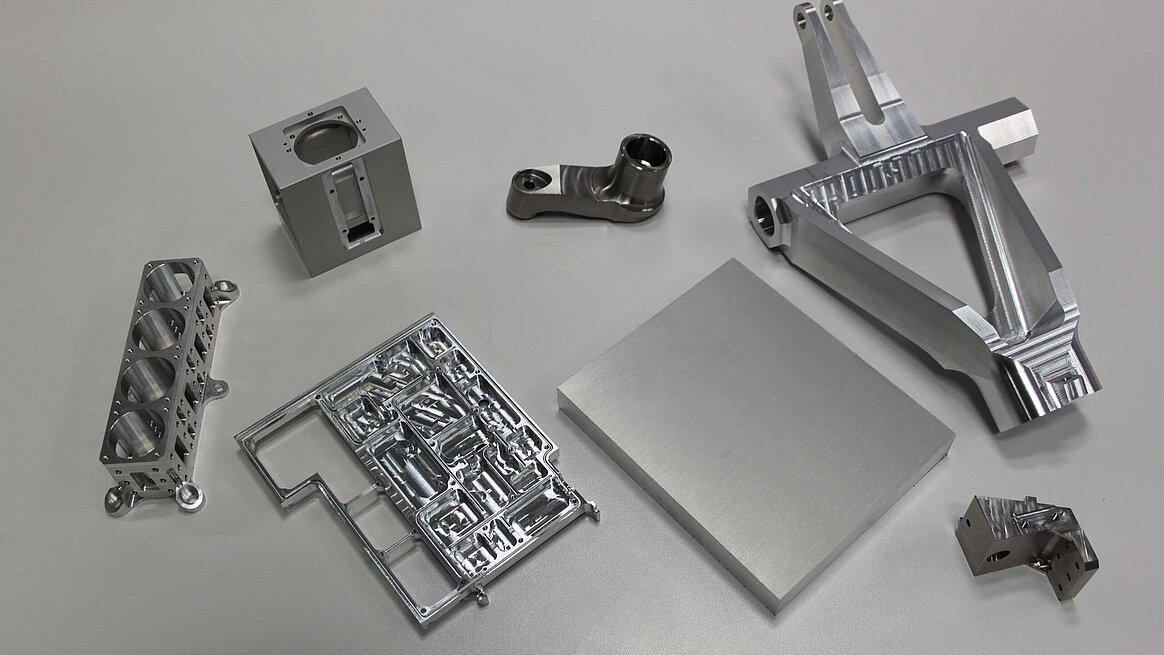

Complex precision parts with batch size as low as 1

Andreas Bauer, Director of CNC Vertical Milling, describes the special requirements for sheet metal processing and machining operations in his department as follows: "We are organised into three Technology Centres with about 350 skilled employees. The equipment includes 65 CNC-controlled turning and milling machines, some with automation. "We normally work in shift operation, manufacturing mainly individual parts and smaller series up to 300 pieces. The proportion of turning to milling work is about 30/70. In terms of total production, about 80% is for internal needs, with 20% for external order manufacturing. In general we need to be competitive in every way, and we face the same challenges as any supplier company in the market in terms of productivity, quality and delivery flexibility. In the Vertical Milling department, which currently has 38 employees, this means that we must consistently rely on our performance and competitive capabilities, which in practical terms consists largely of automated 5-axis/5-sided complete/ simultaneous machining." To be able to respond to these requirements in the long term, we started a streamlining project in 2010 called "Automated (largely unmanned) parts manufacturing", and we began looking for a partner with the experience we needed". While eight different manufacturers of CNC machine tools were previously represented in manufacturing of milling parts at the R & S plant in Teisnach, that changed to nine suppliers during the evaluation phase for procuring highly automated 5-axis machining centres, with the addition of the system and complete solution competence of Maschinenfabrik Berthold Hermle AG, D-78559 Gosheim.

Flexible unmanned manufacturing with process reliability and precision quality

Andreas Bauer, an experienced specialist, added: "Our stated goal, to raise unmanned times significantly and explicitly, was in complete harmony with Hermle's concepts. Perfect presentations were followed by absolutely satisfactory performance records, and we defined the scope of equipment and interfaces in workshops. It turned out to be greatly to our advantage to obtain complete systems from a single source, the first system consisting of two type C 30 U 5-axis CNC high performance machining centres combined with an RS 2 robot and workpiece magazine system, while the second was a C 42 U 5-axis CNC high performance machining centre with integrated 3-fold pallet changing system." The question why the company ordered two different systems with different basic machines (2 x C 30 U and 1 x C 42 U) one after the other received an immediate response: Both smaller and medium-sized workpieces can be machined highly flexibly on the two C 30 machining centres connected with the RS robot system, while the combination of the larger C 42 U/P machining centre with the 3-fold pallet changer makes it possible to machine multiple smaller to medium workpieces and even much larger ones. This ensures a very high level of flexibility in applications and usage despite a high degree of automation. The C 42 U/P equipped with the larger working area can also be used for 5-axis/5-sided complete and/or simultaneous machining of large one-piece parts for internal use or for customers, which can advantageously be done in unmanned shifts depending on runtime and machining time. This also provided the desired increase in capacity in terms of internal and customer-ordered machining and supply services in 5-axis technology.