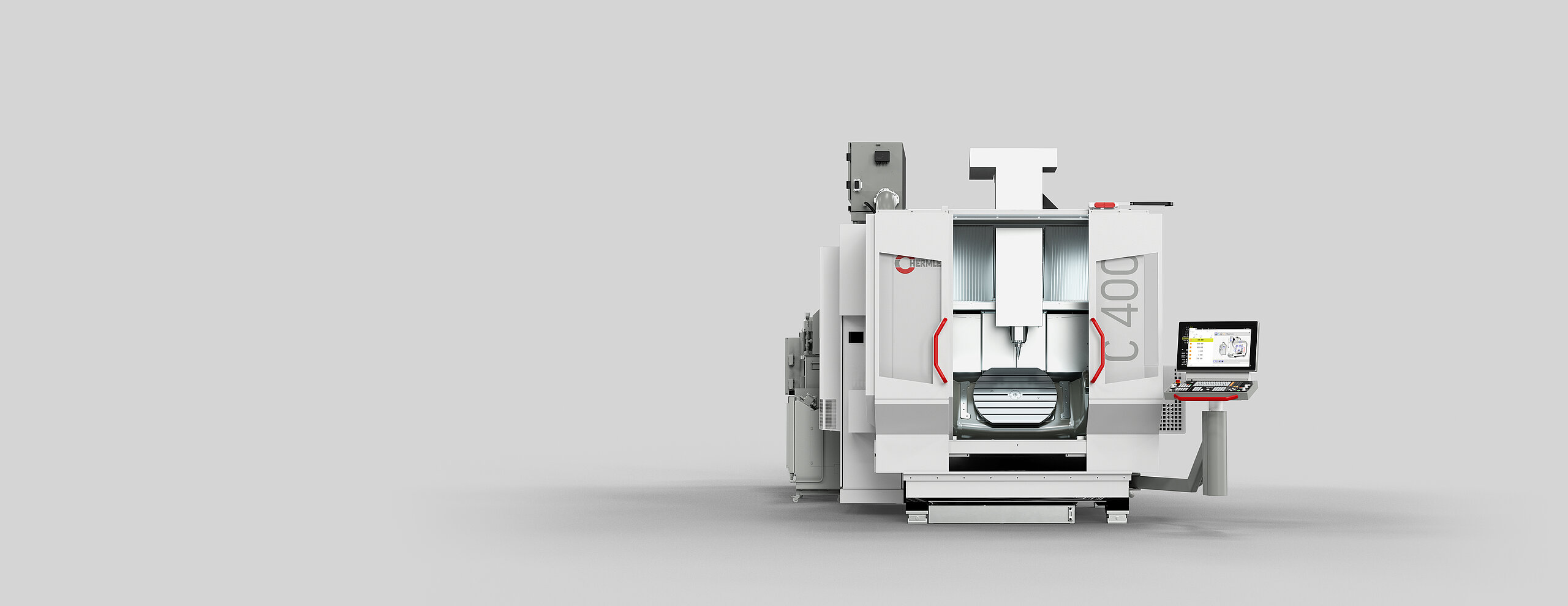

Technical Data

Dimensions

-

Traverse path: 850 x 700 x 500 mm

-

Body: Ø 650 / H 500 mm

-

Collision circle: Ø 885 mm

-

Vertical table clearance: max. 625 mm

Facts

-

Rotational speed: 15000/18000 1/min

-

Rapid traverse linear X-Y-Z : 35 m/min.

-

Rigid clamping table: 1070 x 700 mm

-

Max. table loading: 2000 kg

Applications

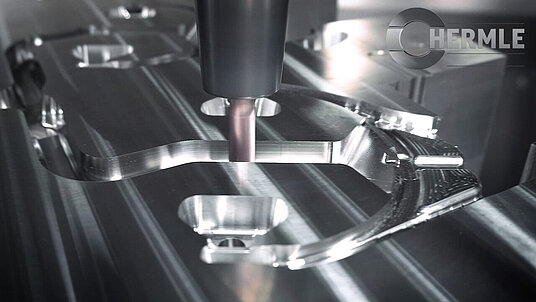

C 400 | Tool and mould making | Moulding plate

HERMLE C 400 in 5-axis version. Machining a moulding plate in 1.2367 for tool and mould making

C 400 | Tool and mould making | Sailboat

HERMLE C 400 in 5-axis version – hybrid manufacturing. Machining a sailboat in 1.4404 for tool and mould making. Blank additively manufactured using MPA technology

C 400 | Model making | Elephant

HERMLE C 400 in 5-axis version. Machining an elephant in AlMgSi1 for model making, workpiece clamping using Lang Makro Grip embossing technology.

User reports

When taking a risk achieves positive outcomes

BRAVO-TECH BVBA

Contract manufacturing

BRAVO-TECH is now a successful contractor based in the Belgian town of Oudenaarde. The company mills, deburrs and polishes moulds for hard-top cases, blades and turbine wheels for compressors and pumps, as well as engine components such as camshafts and crankshafts.

Update only with automation

Cafmeyer

Tool & mold making

Cafmeyer manufactures press moulds. The more complex the part, the more parts needed for the mould. In the past, the Belgian mould maker was sometimes pushed to the limits of its capabilities – both in terms of dimension and capacity. The company therefore decided to invest in a Hermle C 650 U 5-axis machining centre with HS flex heavy automation.

Open and honest, but without the show

Zerspanungstechnik Mangner GmbH

Contract manufacturing

Zerspanungstechnik Mangner chooses quality over loud marketing. The company owner now provides us with a rare glimpse inside the production facility. Nine 5-axis machining centres from Gosheim make up the bulk of the machinery. With them on its side, Mangner is sure it can live up to its delivery promises.