Technical Data

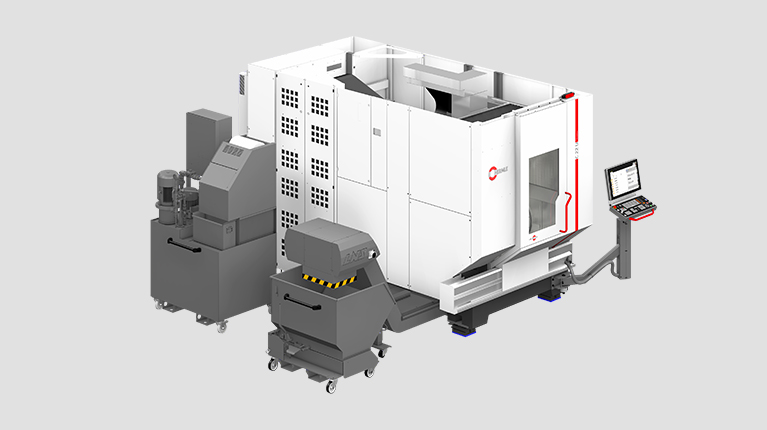

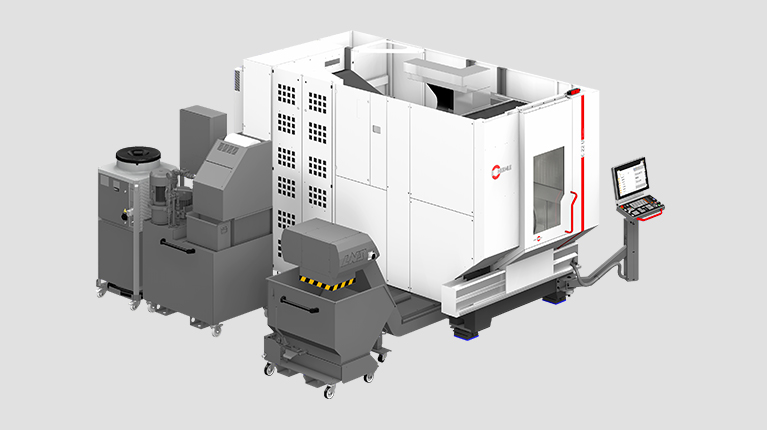

Dimensions

-

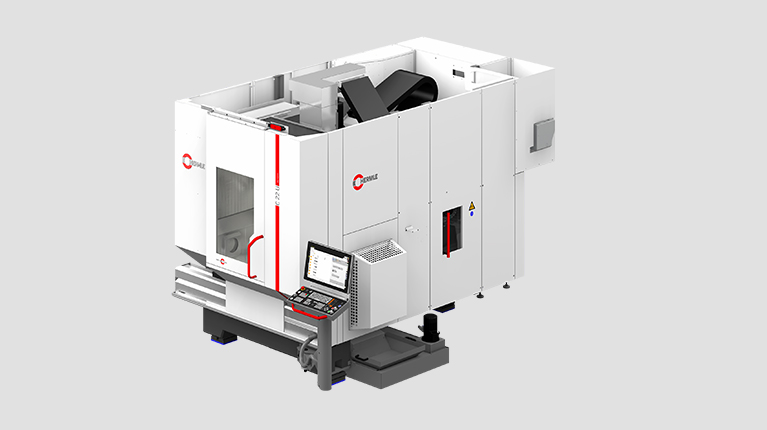

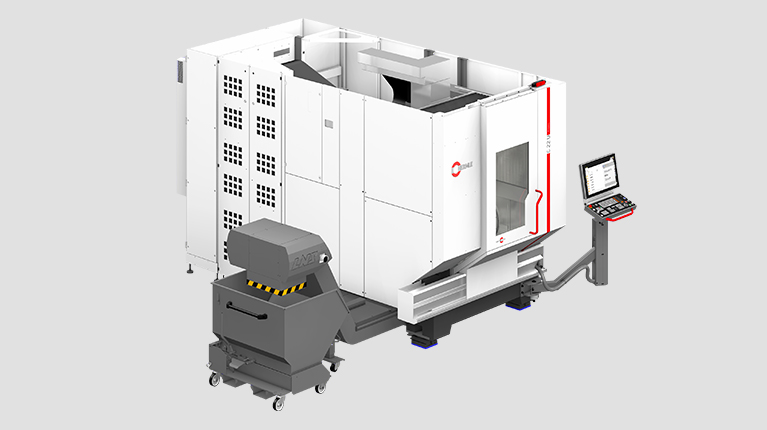

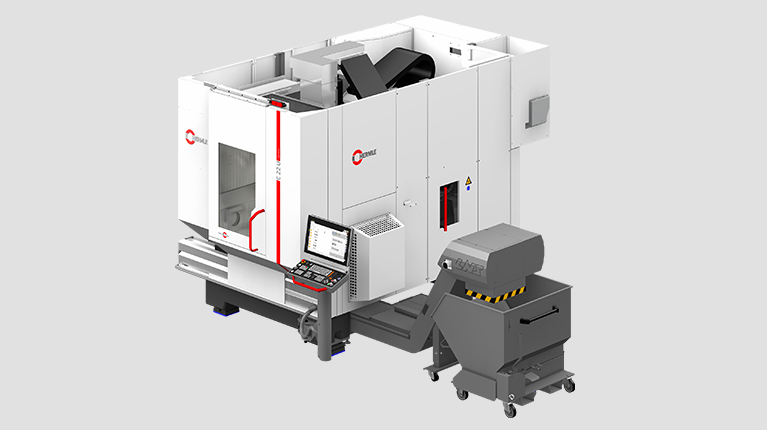

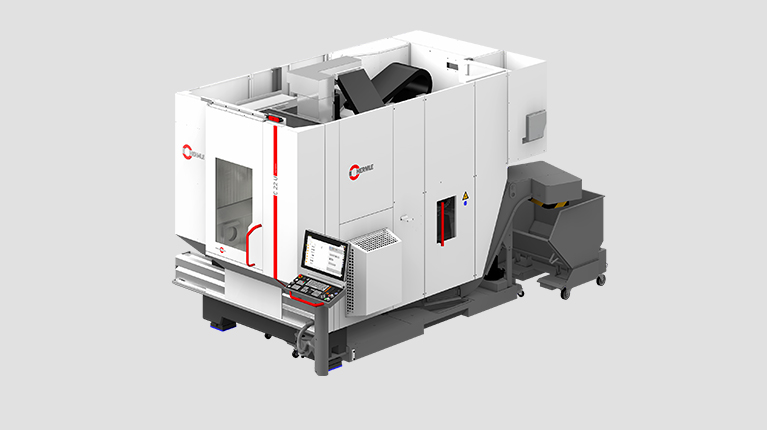

Traverse path: 450 x 600 x 330 mm

-

Body: Ø 450 / H 370

-

Collision circle: Ø 610 mm

-

Vertical table clearance: max. 470 mm

Facts

-

Rotational speed: 15000/18000/25000/30000/42000 1/min

-

Rapid traverse linear X-Y-Z : 30 (50) m/min.

-

Swivelling rotary table: ø 320 mm

-

Max. table loading: 300 kg

Applications

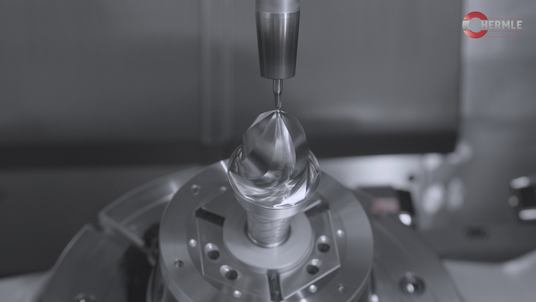

C 22 | Medical technology | Bone plate

HERMLE C 22 U dynamic in 5-axis version, machining a bone plate in grade 5 titanium for medical technology

C 22 | Model making | Soft ice cream

HERMLE C 22 U dynamic in 5-axis version, machining a "soft ice cream" in 1.2083 (HRC 55) for model making

C 22 | Sports and leisure industry | Propeller

HERMLE C 22 U dynamic in 5-axis version. Machining a propeller in 1.4305 for the sports and leisure industry. Only a sample of the component was available. The geometry data was created by scanning and reverse engineering by Staab Tec.

User reports

The perfect 13 – in China | Tool technology

Huarui Precision Cutting Tools

Tool technology

Huarui Precision Cutting Tools' mission is to be one of the best suppliers of cutting tools in China. It has therefore been looking for the best machines for production – and has finally invested in thirteen 5-axis machining centres from Hermle in 2022. Hermle China not only convinced with the hardware.

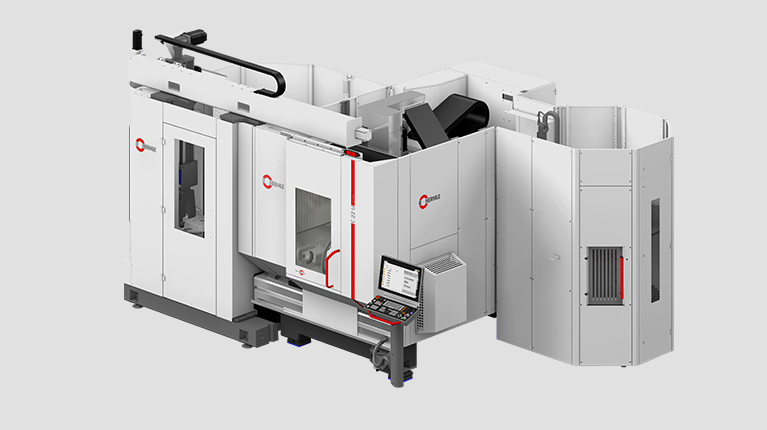

Twins for greater planning freedom

Prokutec

Metal products

These days, Prokutec is a successful metalworking specialist that provides a full range of services for all types of machining. "Our flexibility is our advantage", emphasises Managing Director Michael Beyer. A reliable stock of machinery with automation gives him the necessary capacity. This also includes two identical type C 22 U 5-axis machining centres as well as a C 12 U machine from Hermle.

Dynamic for series production

HIN Feinmechanik

Prototyping

From draft to design through to production: HIN Feinmechanik has successfully established itself as a specialist in complicated components and complex devices. The "Made in Germany" quality seal is important to the owner – including in his stock of machinery: all six milling centres are supplied by Hermle in Gosheim.