The handling system HS flex hybrid– the logical further development for easy entry into automation

HERMLE AG has been investing in the automation of its machining centres for more than 25 years. Simple pallet changers were soon followed by compact handling systems, and robots have played a key role from the start. In the meantime, HERMLE has made a name for itself through its automation solutions and successfully added a second string to its bow. The customer purchases both main components from a single manufacturer and has just one point of contact in the event of service issues. “Everything from a single source” is more than just a slogan at HERMLE; it is a real and valuable advantage that is valued by customers just as much as the HERMLE service benchmark.

Our handling systemsHS flex and HS flex heavy demonstrate their efficiency daily in numerous companies and a multitude of applications for the automated production of a wide variety of parts.

The handling systemHS flex hybrid is helping us take HS flex to the next level of performance for the economic manufacture of components weighing up 450 kg. The system transports both pallets and vices from the setup station to the storage modules or the working area. The following components have all been specially configured for the HS flex hybrid – storage modules, setup station, gripper and adapter pallet. Further, the HS flex hybrid can be adapted to six different machine models and configured with either one or two storage modules.

Modifications to the standard system

- Table modification with media transfer

- Lockable setup station

- Exchangeable gripper for base plates

- small and large vices

- Special storage module for even more storage

The advantages again at a glance

- Max. flexibility through the use of pallets and vices

- Up to five times more capacity

- Retention of the popular setup strategy

- Intuitive operation

- HACS HERMLE Automation-Control-System – the intelligent order management system

- Can be adapted to machine models C 12, C 22, C 32, C 42, C 250, C 400

-

One of two storage modules with high workpiece capacity -

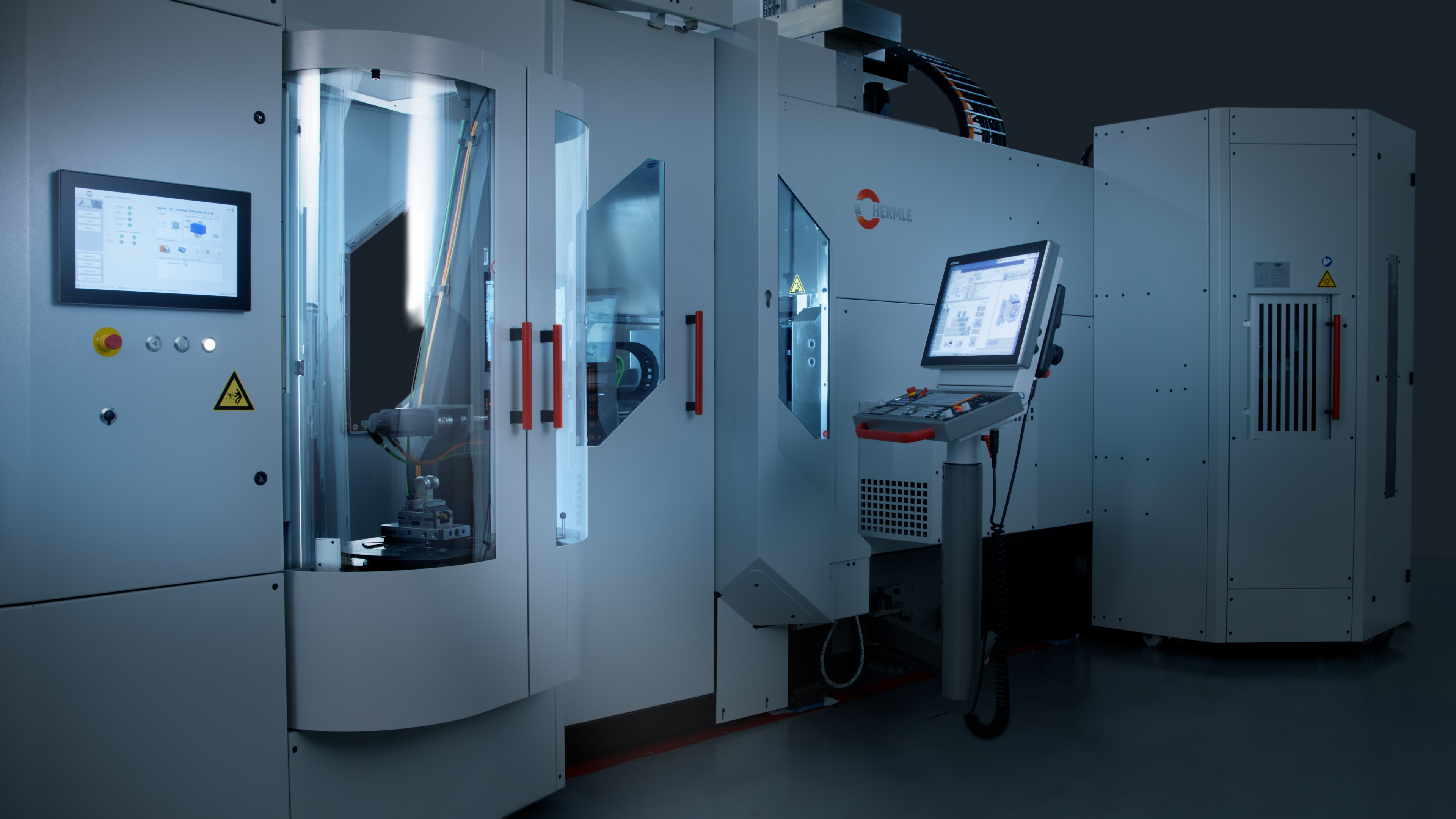

Operation terminal with HACS software (HERMLE Automation-Control-System)

on the handling system HS flex hybrid -

Automated night shift with the handling system HS flex hybrid -

Changing a vice and workpiece on the handling system HS flex hybrid -

The handling system HS flex hybrid with two storage modules

adapted to a C 400 five-axis machining centre

A typical setup that can be found in many production plants: The machining table is fitted with an adapter for raising the structure, thus creating more space for machining when the unit is swivelled. On the adapter, there is a vice and a workpiece – a standard setup for non-automated machines. The advantage of the HS flex hybrid, which can also handle vices, is that owners do not need to change this setup. Concerns about the complexity of this type of automation are unfounded, as the proven working method remains unchanged, and workpieces can still be clamped in vices. The key advantage of the HS flex hybrid is that this setup no longer needs to take place in the machine after it has come to a standstill. Setup now occurs at the HS flex hybrid setup station. The vices and workpieces are stored in racks on the HS flex hybrid, where an active gripper of the HS flex hybrid automatically loads the vices into the machine – using a straightforward pick-and-place method. This ensures that production continues without disruption. The perfect solution for both small-scale production (high level of variance and small batch sizes) and large-scale production (enabled by quick and easy setup during non-productive periods and increased capacity). Moreover, the system remains flexible for large and heavy components. The ideal solution for handling and machining components of any shape and size – simply, universally, flexibly and efficiently. Everything on a single machine and everything from a single source.

A video on our YouTube channel shows a setup example: HERMLE HS flex hybrid C 250 / C 400 (DT).

Contact details for journalists/editors:

Maschinenfabrik Berthold HERMLE AG / Marketing Department / Email: marketing@hermle.de / Phone +49 (0)7426 95-0

78559Gosheim