5-axis-concept to increase manufacturing capacity

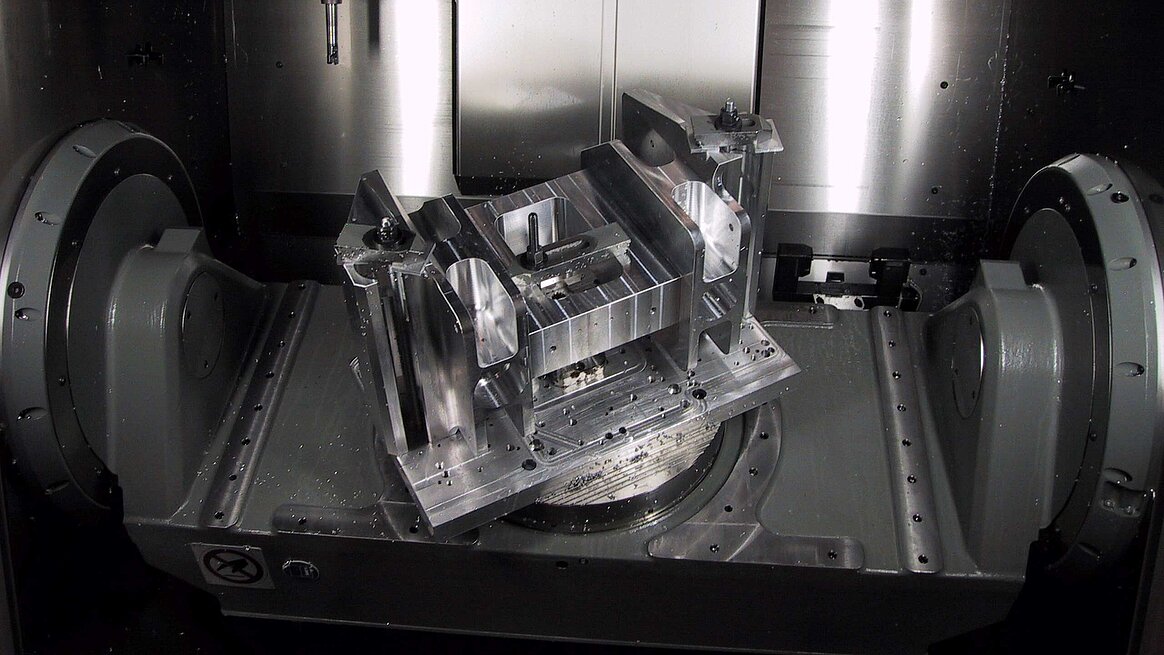

C 32 U | VMV Teknik | Tool making

The Danish machine and toolmaking company VMV Teknik decided to invest in a new 5-axis machining centre from Hermle to extend its manufacturing capacity. Since last year, the C 32 U is completing even complex jobs in a reliable and precise way.

"Our customers come to us with high demands on quality and precision," Henrik Brejning Jensen sais. He is the Technical Director from VMV Teknik ApS in Vejle, Denmark, about 70 kilometres south of Aarhus. The Danish machining specialist produces tools for the synthetic materials industry as well as machine parts and workpieces for the offshore industry and machine builders. Jensen aptly sums up the current challenges for toolmakers: "Each step is important to achieve that the workpieces can have the required precision – from design over measurement up to precise machining." Finally the customer gets complex workpieces of titanium, Inconel and other materials. The machine pool must be correspondingly versatile and reliable: In addition to turning lathes, amongst others, 3- and 4-axis milling centres are available for machining – among them also an older C 40 U machining centre from Maschinenfabrik Berthold Hermle AG.

"The increasing demand induced us to develop a concept enabling us to further enhance our manufacturing capacity," Jensen sais. The decision on a 5-axis milling centre was taken quickly, and the manufacturer chosen just as quickly. "As we had gained very good experiences with the C 40 U, we again opted for a Hermle machine," the Technical Director explains. Consequently, VMV Teknik last year ordered a 5-axis milling centre of the C 32 U type.

The machining centre of the high performance line is equipped with a compact spindle reaching the maximum speed of 25,000 revolutions per minute. In addition, the Danish toolmaker ordered a simple additional magazine to provide space for 192 further tools, as well as an 80-bar-internal cooling. With the C 32 U, the company can precisely machine workpieces up to the weight of 300 kg and the dimensions of 650 x 420 mm (diameter x height). VMV Teknik additionally had the new machine prepared for retrofitting with Hermle's HS flex handling system. There is thus no further obstacle to automation.

Outlook on the greater

But there's more to it than the outlook on an enhanced Hermle handling system. "We are already thinking about when we can plan the next investment. We have another 5-axis machining centre from Hermle in mind – this time one of a greater series," Jensen reveals and continues: "It is essential for this that we can also precisely and productively solve even complex tasks at the same time with it. We will achieve this with an Hermle machine."